By SCOTT JORDAN, Director of NanoAutomation Technologies, and

STEFAN VORNDRAN, VP Marketing,

Physik Instrumente (PI),

www.pi-usa.us

A high-speed head positioner in a hard-disk track profiler; a sensitive tip/tilt planarization mechanism for a semiconductor wafer chuck; a dimensionally-stabilized laser cavity; an active mirror-segment positioner for an advanced telescope; a fast-actuating nano-focus device in a research microscope, improving our understanding of proteins and DNA and helping to unveil the secrets of disease. These are all examples of mechanisms whose design integrates piezoelectric flexure actuators – plug-and-play subsystems based on solid-state piezo actuators combined with flexure guidance and amplification elements, and optional position-feedback sensors.

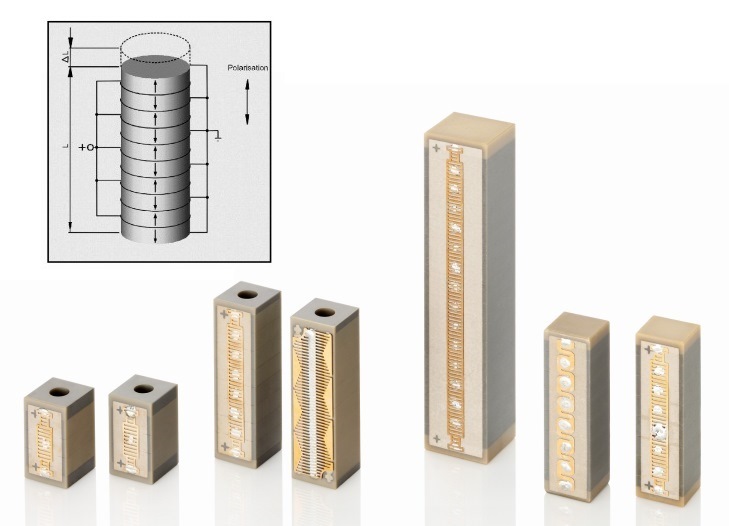

At the heart of piezoelectric flexure actuators is an exquisite stack of layers of specialized ceramic, only a few dozen microns thick, interleaved with electrodes and sintered into a solid structure (Fig. 1 ). The most common piezo ceramic for high-performance positioning applications is PZT (lead-zirconate-titanate), a ferroelectric ceramic. This material is useful for positioning because PZT ceramic exhibits a small but almost linear dimensional change as voltage is applied across the electrodes. This provides a precise, controllable motion input to the engineer’s mechanism. Position changes on the order of nanometers can be achieved without difficulty.

Fig. 1: The basic design of a piezo stack actuator (inset) results in a variety of ceramic insulated piezo stack actuators, either standard or with aperture.

The operation of the ceramic element is characterized by four factors: a) precision; b) speed; c) short travels; and d) high force.

The stack’s positioning precision comes from its almost-linear dimensional change, which is free of stiction effects and can allow controllability down into the sub-nanometer range. This is why piezoelectric mechanisms are at the heart of today’s semiconductor lithography tools, atomic-force microscopes, and the other nanoscale-precision systems.

Speed comes from solid-state actuation of the stack, which propagates at the speed of sound (Mach 1) through the material, yielding responsiveness into the kHz region, with correspondingly impressive force capability. The Mach 1 actuation also means that piezo actuators can respond to an input in microseconds, a feature that makes them suitable to applications such as valve control and nano-dosing where nanometer precision is only infrequently of secondary importance.

The ceramic element's travel limitation comes from the maximum strain the actuators can achieve, typically about 1% of their length. Consequently, piezoelectric flexure actuators use frictionless lever amplifiers to magnify the actuator motion. Clever design means motion ranges of up to 2 mm can be achieved in compact packages. Until recently, piezoelectric flexure actuators have mostly been employed inside specialized piezoelectric stages for ultra-precision positioning applications, and were not easily available to the OEM engineer. That has changed, and flexure actuators with long travels are now available as off-the-shelf items for ready integration into custom mechanisms. This new accessibility has opened the door for a wide variety of specialized mechanisms across a broad spectrum of industries.

Force characterization will be discussed in more detail following a look at some of today's actuators.

Broad choices, new options

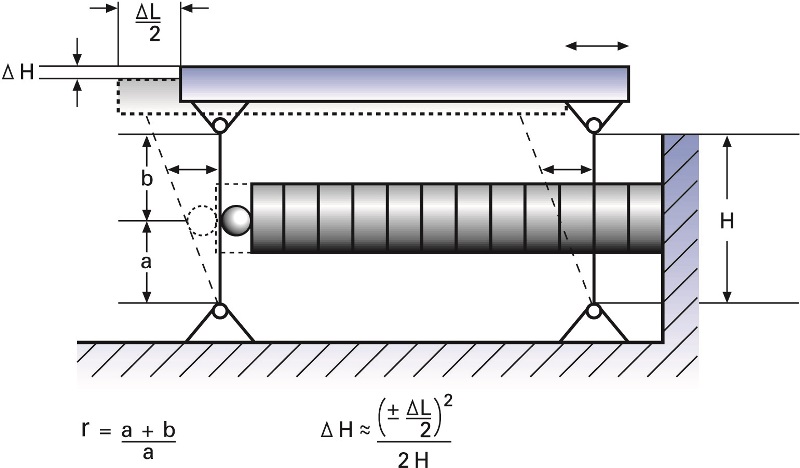

The new piezoelectric flexure actuators complement and extend the existing portfolio of form-factors and packaging styles for piezoelectric actuators. Ceramic stacks – with or without integrated position sensors – have traditionally been available to engineers wishing to perform all integration, while packaged actuators have commonly been used for applications needing easy mounting and integral low-stiction preloads for dynamic actuation. The new breed of fully integrated flexure actuators (Fig.2 ) now offer preconfigured subassemblies which integrate stictionless lever amplification (Fig.3 ) as well as preload elements and optional position feedback. Thus, piezoelectric flexure actuators offer especially easy mounting for the greatest convenience and performance for research and OEM applications, and they require the least specialized engineering to design-in and implement. All of these choices share the common benefits of piezoelectric actuators, such as nanoscale precision, high speed and force, solid-state and lubricant-free actuation, non-magnetic and field-free operation, and vacuum compatibility.

Fig. 2: Piezo flexure amplified actuators are now available in different customization levels, from low-cost OEM actuators suited to drive micro-pumps to complete closed-loop nano-focus positioning systems.

Fig. 3: For the piezo flexure actuator seen above, with a simple parallelogram flexure guiding system and motion amplifier, the amplification, r (transmission ratio), is given by (a+b)/a.

Piezo force generation

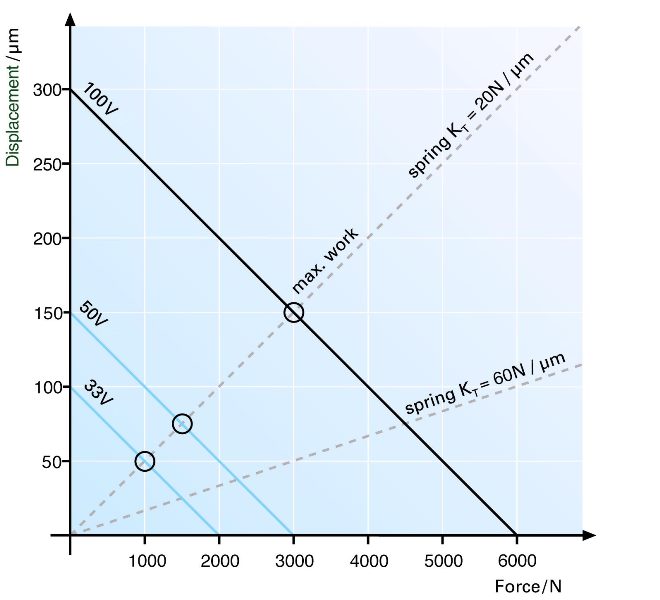

Piezo flexure actuators are used for precision positioning, as well as for moving things quickly, and for force generation. Force generation usually means pushing against an external elastic material.

Fig. 4: In this force generation vs. displacement plot of an ideal piezo actuator (displacement 300 µm, stiffness 20 N/µm) working against an external spring, the points where the dashed lines (external spring curves) intersect the piezo actuator force/displacement curves determine the force and displacement for a given setup with an external spring. The stiffer the external spring (flatter dashed line), the less the displacement and the greater the force generated by the actuator. Maximum work is generated when the stiffness of the piezo actuator and external spring are matched.

As Fig. 4 shows, working against a load reduces the available travel of an actuator, according to a simple formula for the maximum effective force (Fmax eff ) that a piezo actuator can generate in a yielding restraint:

Fmax eff = kT • ΔL0 [1 – kT /(kT +kS )]

where ΔL0 is the maximum nominal displacement without external force or restraint (m); kT is piezo actuator stiffness (N/m), and kS = stiffness of external spring (N/m).

Stiffness, responsiveness

The additional motion provided by flexure-amplified piezo actuators does, however, come at a price. With increasing amplification ratio, both stiffness and responsiveness are reduced. Nevertheless, well designed piezo flexure actuators can still provide submillisecond step-and-settle times, significantly faster than any other conventional actuator.

The following relations apply to (ideal) motion amplifiers for any primary drive system:

ksys = k0 /r2 , ΔLsys = ΔL0 • r, fres-sys = fres-0 /r

In this formula:

r = motion amplifier ratio;

ksys = stiffness of the lever-amplified system (N/m);

k0 = stiffness of the primary drive system (piezo stack and joints) (N/m);

ΔLsys = travel of the lever-amplified system (m);

ΔL0 = travel of the primary drive (m);

fres-sys = resonant frequency of the amplified system (Hz);

fres-0 = resonant frequency of the primary drive system (piezo stack and joints) (Hz).

Resonant frequency is directly proportional to the responsiveness of the system.

One size won't fit all

With the variety of parameters such as size, force, precision, travel range and cost, it is obvious, that one flexure actuator cannot fit all applications. Often, a standard part may come close enough to be integrated in a prototype, however, for optimized cost and performance it usually pays off for the OEM mechanical system engineer to work closely with an experienced piezo mechanism manufacturer. Prototypes of custom designs can be prepared within as little as a few weeks.

Regardless of the form-factor, the latest designs of piezoelectric actuators are very reliable mechanisms. They must be, since they are the mission-critical heart of so many industrial and research applications, ranging from semiconductor fabrication to atomic-force microscopy. After all, they are structurally quite similar to ceramic capacitors, which are ubiquitous in electronics.

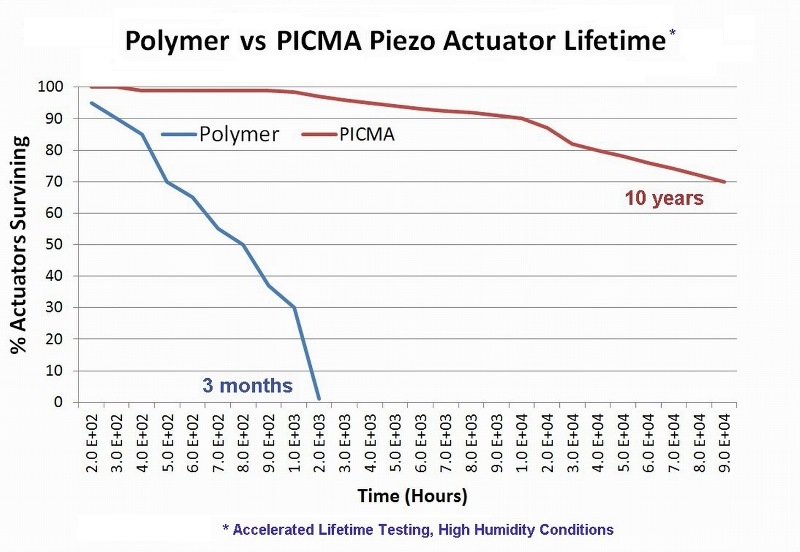

However, they can be sensitive to humidity. Previously, PZT stacks were encapsulated by painting them with a polymer coating. This provided a small amount of protection against infiltration by ambient water vapor. Far more effective is the patented construction of PICMA® model actuators – developed by Physik Instrumente (PI), which has played a pioneering role in advancing the development of piezo devices – incorporating a hermetic ceramic coating and many subtle design details which ensure long life even in the presence of high humidity. PICMA stacks are used in all PI flexure actuators.

The solid state, frictionless design means wear and tear are not an issue when it comes to lifetime. Recent tests for space qualification of PICMA actuators have shown that even after 100 billion cycles the actuator performance only dropped by a few percentage points. These actuators are now used in the Mars Science Laboratory on the Curiosity rover’s Chemln particle analyzer instrument.

Fig.5: High humidity lifetime testing results clearly demonstrate PICMA ceramic insulated actuators' lifetime advantage.

Expanding the motion spectrum

Piezoelectric flexure actuators are but one utensil in a deep toolbox of motion technologies driven by piezoelectric principles, which include:

- Piezo ceramic stacks;

- Packaged, preloaded stack piezo actuators;Piezo flexure actuators;

- Piezo linear motors with long travels and nanoscale position-hold stability

- a) Walking motors for high push/pull and holding force;

- b) Ultrasonic resonant motors for high speeds;

- c) Incrementing inertial motors (stick/slip) for low cost.

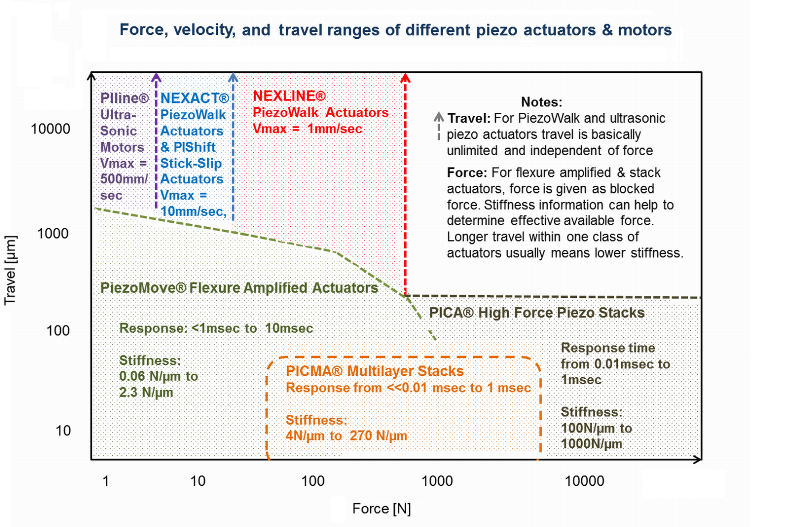

Each of these piezoelectric tools extends the capability spectrum of piezoelectric motion – a spectrum which has expanded dramatically in breadth and depth in recent years (Fig. 6). Thus piezoelectric flexure actuators can offer unmatched ability to drop into a custom assembly and provide fast, precise actuation without fuss and bother, and with demonstrated reliability that extends to the many billions of cycles. Recently-introduced integrated flexure actuators offer a new level of convenience and performance for the designer, as they come complete with stictionless lever amplifiers for long travel, built-in preloads for high-dynamic operation, and optional feedback sensors for high-performance servo-control.

Fig. 6: Comparison of force, speed, and travel capabilities of different piezo-based drive systems.

As a result, piezoelectric devices are increasingly being used by product designers and incorporated successfully into a widening range of applications where precision motion control is needed. These devices are compact, require low voltage, deliver high torque, exhibit short response time, generate little heat, are both nonmagnetic and vacuum compatible, and have few mechanical component parts to wear out and service. Now, the latest generation of piezoelectric flexure actuators deliver an even broader product development capability for OEM designers.

About the Authors

Scott Jordan is Director of NanoAutomation Technologies for Physik Instrumente L.P. A physicist by training with an MBA in New Venture Management and Finance, he publishes frequently on nanotech developments, including novel instrumentation, software and microscopy techniques.

Stefan Vorndran is VP of Marketing at Physik Instrumente L.P. He holds a Dipl. Ing. degree in electrical engineering from University of Darmstadt/Dieburg, Germany. He has held several positions in sales, product management, and applications support of piezo technology and precision motion control equipment at Polytec PI, Inc and at the Physik Instrumente in Germany. He may be contacted by phone (508-832-3456) or e-mail ().

Advertisement

Learn more about Physik Instrumente