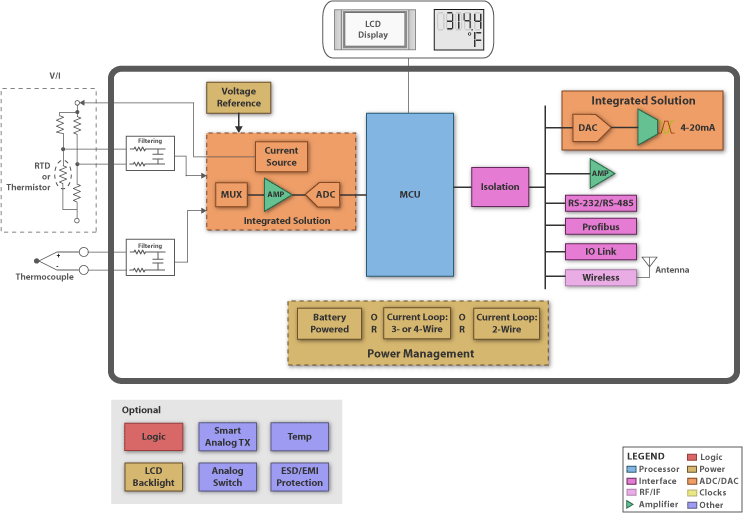

Temperature Sensor solutions are used to measure temperature and have a wide range of uses in industrial, commercial applications. Temperature measurements are made using RTD (Resistance Temperature Devices), Thermistor or Thermocouple.

RTD and Thermistor utilize the property of Change in Resistance according to temperature to measure voltage drop across the element and calculate the temperature. A thermocouple is a junction between two different metals that produces a voltage related to a temperature difference, known as Seebeck effect. Ambient temperature is added to this calculated temperature difference to measure actual temperature. The process of measurement of Ambient Temperature is known as cold junction compensation.

Temperature transmitters are of two types. The conventional Field Transmitters working as a part of Industrial control loop that are line or loop powered and the Wireless or Handheld temperature sensors that are battery powered.

Excitation Technique: RTDs and Thermistors being passive elements need a current excitation source to make measurements. Highly stable and accurately matched current sources with low drift are critical to making 3 wire RTD measurements. TI’s temperature sensor front-ends have high precision on-chip current sources. Accurate measurement of the ambient temperature for Cold Junction compensation in Thermocouple measurements can be made using the high accuracy on chip temperature sensor. Thus the TI analog front-end for temperature measurement is a single chip solution that provides all aspects of signal conditioning needed for RTD, Thermistor and Thermocouple measurements.

Signal Conditioning/Signal Acquisition and Processing: The output range of the temperature sensor is very small and thus the signal needs to be amplified before processing to prevent introduction of errors. The signal chain has to handle the small signal accurately in presence of noise. TI’s temperature sensor front-ends have an input multiplexer, high impedance PGA and high resolution sigma-delta modulator all integrated into a single chip. The low noise, chopper stabilized PGA provides the versatility of scaling the gain as needed in accordance with how small or large the output from the sensor is. High end products also have integrated features for system diagnostics and fault monitoring. A further level of system calibration could be implemented in the MCU.

Interface and Communication: Traditional analog (4 – 20mA) interface remains the popular choice for industrial control and sensor applications. The other popular protocols include HART, Profibus and IO-Link. TI's IO-Link interface products have integrated regulators and diagnostic outputs. In addition, wireless options based on IEEE 802.15.4 protocols are becoming more prevalent. TI is committed to provide solutions for both traditional and emerging industrial interfaces.

Power Management: The Field Transmitter can be powered in one of three ways. Line powered transmitters are commonly powered by voltage rails of 12V, or 24V. Loop powered transmitters are powered by the 4-20 mA loop. Such transmitters require extremely low power architectures as the entire solution has to be powered off the loop. TI provides high efficiency Step Down converters with low quiescent current and low output ripple appropriate for Line and Loop powered transmitters. Battery powered transmitters powered can be designed using TI's low power Buck and Buck-Boost converters. The DC/DC buck converters offer over 95% efficiency over a wide battery voltage range, even with input voltage down to 1.8 volts extending battery life. Special Buck-Boost converters generate a stable required output voltage and supply constant current for over- and under-input voltage conditions and support various battery configurations.

Microcontroller: The Hercules™ Safety MCUs offer an ARM Cortex-R4F based solution and are certified suitable for use in systems that need to achieve IEC61508 SIL-3 safety levels. These MCUs also offer integrated floating point, 12 bit ADCs, motor-control-specific PWMs and encoder inputs via its flexible HET Timer co-processor. Hercules Safety MCUs can also be used to implement scalar and vector-control techniques and support a range of performance requirements.

Download Full Block Diagram Below

Advertisement

Learn more about Texas Instruments