By Brian Santo, contributing writer

3D printing has proven itself as a low-volume option for one-offs, prototypes, and — for those determined to use 3D printing — low-volume production. Regardless of the material, be it plastic, concrete, metal, or something else, 3D printing is a serial-production technology, and serial production will always be slower than parallel production. That doesn’t mean that 3D can’t be used for production; it’s just that nobody has figured out a way to accelerate the process to production-volume speeds — until now.

Desktop Metal has devised a technique that it says is not only 100 times faster than extant 3D metal printing systems but can also do metal printing 10 times less expensively. It is preparing to market two systems: an economical model for low-volume use and another for production-volume use.

As of a few months ago, the company still didn’t have a final product , but what it has been able to demonstrate thus far has earned it an impressive amount of confidence — $212 million worth of it. That’s the total venture capital that the company has attracted thus far, including a recent series D financing that brought in $115 million from some of Silicon Valley’s most prominent money houses, including Google Ventures, along with BMW, GE, and even a nominal rival, 3D-printer-maker Statasys.

To date, metal printing has differed from the more common plastic 3D printing. Plastics can be heated and deposited, with each successive layer naturally bonding to the layer below as it cools. Metal printing, conversely, has relied on the use of lasers to sinter successive layers of metal powders. These printers are expensive, slow, and require trained staff to operate. They tend to be used for highly complex and specialized parts.

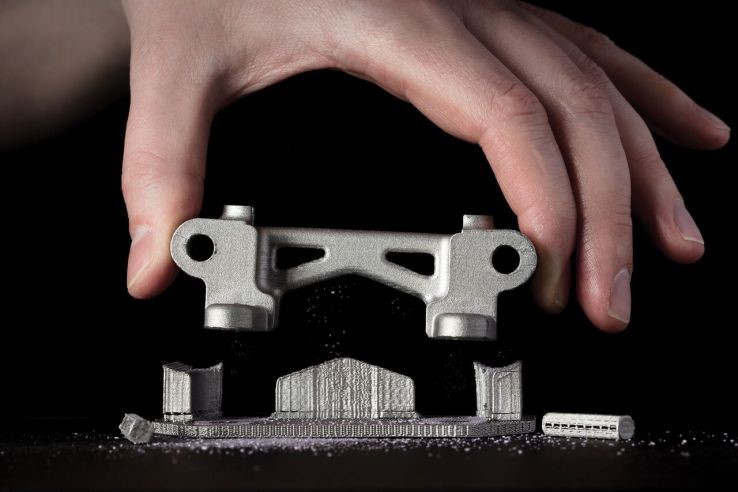

Desktop Metal is a startup founded in 2015 by several researchers from MIT, including co-founder Ely Sachs, who filed one of the first patents on 3D printing. The company has devised a method in which metal powders are mixed with a flowable polymer binder. The printer extrudes the substance layer by layer in a manner more similar to plastic printers. The binder “clumps” the metal powder into the intended shapes, as the MIT Technology Review explained it. Each part goes through a debinder (which removes much of the polymer binder) and a single sintering step.

The low-volume system is able to print up to 24 cubic inches a day, with a maximum resolution of 50 microns, according to the company.

In part because there are no lasers involved, the system can be easily maintained and easily operated, according to the company. All you need, the company says, is “power and an internet connection” — the design system is cloud-based.

The materials that Metal Desktop uses are widely available, as they are used in metal injection molding (MIM). The variety of printable materials includes several types of steel, aluminum, and titanium, along with superalloys (Inconel, cobalt chrome, Hastelloy). So why not just use MIM? Metal Desktop’s 3D metal printing promises to be faster and more precise.

The company plans to introduce its low-volume model shortly. The printer, debinder, and furnace together will be $120,000. The company plans to introduce the high-volume version next year.

With that model, the company will end up competing less with other 3D printer manufacturers than with the entrenched metal-working industry based on traditional forging, casting and stamping. On the one hand, that’s a formidable challenge, but on the other hand, the global metal-working business is enormous, and the company needs to capture but a fraction of a percent of the market to thrive.

In addition to the expected mix of venture capitalists, investors in Desktop Metal include BMW, General Electric, Lowe’s, Saudi Aramco, and Stratasys. The venture financiers include Kleiner Perkins Caufield & Byers, Google Ventures, Lux Capital, and Shenzhen Capital Group, among others.

Advertisement

Learn more about Electronic Products Magazine