When Curtis Kirk, CEO of Playmate Enterprise (Tyler, Texas), was ready to have his company’s first professional PCB assembled for its Music Mate product, he thought it would take a couple of months from start to finish. Instead, to his surprise, a week from delivering files to Advanced Assembly, he had the working PCB in hand, and was ready to go.

The Birth of the Music Mate

The Music Mate, a light-sensitive and sound-reactive LED coaster, was developed as a college electronics project when Curtis was tasked with creating a unique electronic circuit. Drawing from an experience on a camping trip when a friend held a flashlight to the bottom of a water bottle and it amplified the light, combined with his love for music, the idea hatched. The school assignment progressed using components purchased at a hobby store and, upon completion a provisional patent was filed after research ensured nothing quite like it was on the market.

While the coasters target the entertainment/party market segment, in addition to being able to “see” the sound of music being played, the device can also be used to check for over-modulation for a live music event to make sure that highs, mediums, and lows of sound are adequately represented.

The coaster design separates audio frequencies, representing the frequencies visually using three LEDs per channel. Operation requires three conditions:

1) There must be a glass sitting on the top of the coaster that applies sufficient pressure to initiate use,

2) An adequately dark environment for the relay to enable the device to switch to open, and

3) Sound to drive a triple-band pass circuit to translate audio into light.

Development Process

Building prototypes with hobbyist components solidified the design concept. Obtaining components that were tiny enough to put in a small case was a different matter, since most of the components Curtis used to make the prototype were quite large. At this point the objectives for the design became small footprints, performance, and an attractive but affordable product.

Figure 1: The Music Mate in operation. The small coaster delivers a powerful visual aspect to music in the environment.

Figure 1: The Music Mate in operation. The small coaster delivers a powerful visual aspect to music in the environment.

In addition to shrinking the design, Curtis also had to scale the LEDs correctly. Initially, the LEDs selected were smaller than required to give off sufficient light. Another obstacle was the power source, necessitating a move from cylindrical-cell batteries to a 9 V battery source.

All of the components also needed to fit within a 2.5″ radius. Given that the original components used were geared toward hobbyists, making the design small enough that it could be manufactured and not just soldered together was problematic.

PCB Criteria

With a better understanding of the challenges that would need to be overcome to take the product to market, Playmate Enterprises established well-defined criteria with which to conduct its PCB partner search. Those criteria included:

• An American-based partner

• Sufficient size to be able to handle orders efficiently

• Credibility in the marketplace

• The willingness/ability to fill small batch orders

• The capability to make changes quickly, if necessary

• Affordability without compromising quality

Based on a Google search of PCB manufacturers, contact with several potential partners was attempted, but, “Disappointingly,” says Curtis, “They’d take my name and number, and I’d never hear back from them.”

Finally, two potential manufacturers were identified that fit the company’s specific criteria. One vendor, however, estimated a cost that was thought to be unrealistically high, given the scale of the project. Advanced Assembly, in comparison, provided not only a cost basis that the company considered fair; they also exhibited excellent communications from the onset.

“Brad Mahoney, the Regional Sales Executive at Advanced Assembly, made it easy. Every time I had a question about a capacitor or an LED or whatever, I got very responsive answers to my questions. He was extremely cooperative. I wasn’t made to feel like I was hassling anybody.”

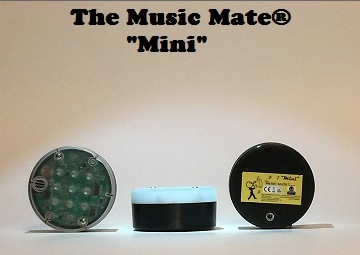

Figure 2: The Music Mate “Mini” is a 3″ unobtrusive coaster that enables users to “see” sound.

Figure 2: The Music Mate “Mini” is a 3″ unobtrusive coaster that enables users to “see” sound.

The Results

Once the circuit was scaled down by TGI Electronics, the files were turned over to Advanced Assembly. After the boards were received, the actual assembly time only took two days, so although the quote indicated a 10-day turn, it was ready and available in just seven days.

“I was surprised at how easy it actually can be to get a board manufactured on a professional level,” said Curtis. “I thought it would not be cost-effective, but it was. Also, I figured I would have to wait for a long time because I am a small company with a smaller order. However, the turnaround was amazingly fast.”

When asked about the benefits of handing off his design to Advanced Assembly, Curtis had this to say: “I did my work with the hobby-level components to make sure that the design worked. If I had tried to assemble the board myself, it would have been a mess. For a minimal amount of money to not have to go through the frustration that I would have gone through was invaluable. Also, Advanced Assembly has a unique design-for-assembly check that caught and corrected a few errors for me. This extra benefit saved me months of debugging time.”

He added, “I couldn’t have gone to the next level of my design without Advanced Assembly working with me on this, within my budget, and very quickly; it was everything I needed.”

The Future

At this time, Playmate Enterprise is hard at work in the launch-phase of bringing the Mini Mate to market, and additional Music Mate designs are on the drafting table. All products will continue to revolve around the same functionality, but will feature increased input and connectivity options with larger open-source development boards, Bluetooth, and more, all targeting specific applications.

Asked if he would do anything differently regarding PCBs for his next product, Curtis indicated that he would listen to Advanced Assembly’s recommendations and place multiple small quantity orders as needed rather than too many boards at once. “Other than that, no,” he said. “Advanced Assembly provided exactly what I needed.”

By: Carolyn Mathas

Advertisement

Learn more about Advanced Assembly