By Dr. Vijaya Kayastha, lead device development engineer, Brewer Science, Inc.

Temperature measurement has long been vital to most industrial and manufacturing operations. It has taken on new importance in the era of smart buildings and homes, where automation of such functions has become more sophisticated and requires solutions that are more streamlined and easier to implement.

Measuring and maintaining consistent temperature can be accomplished by one or more temperature sensors, with different types of sensors offering different advantages depending on the application or environment in which they’ll be used. The advent of silicon sensors broadened the ways in which temperature can be measured, and printed electronic (PE) technology has, quite literally, brought new flexibility to this important function.

Types of temperature sensors

In general, a temperature detection circuit, regardless of the sensor type employed, monitors ambient temperature, keeps the system apprised of the actual temperature, and sends a notification when the temperature passes a specified threshold range. This “early warning” triggers the system to take preventive action to lower or raise the temperature as needed. Let’s take a look at the main types of temperature sensors and their basic pros and cons before delving into today’s newest sensing technology.

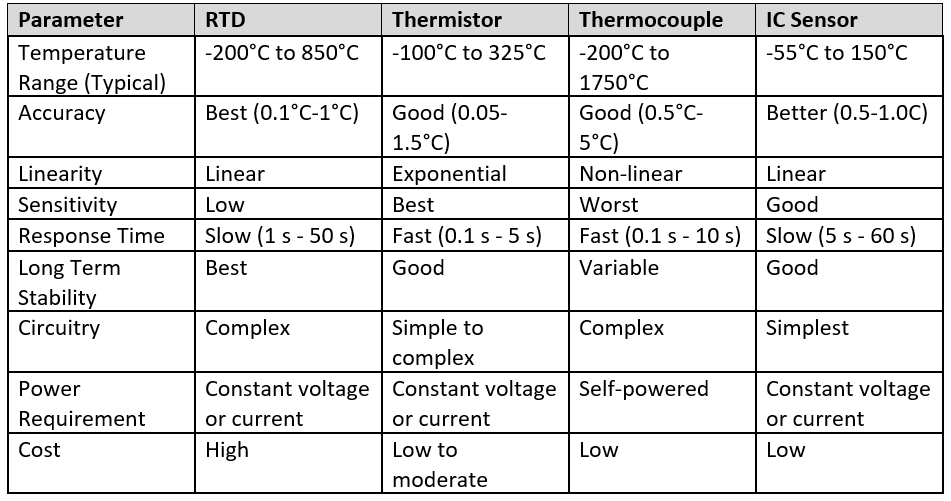

Table 1: Comparison of typical temperature sensor types.

- Thermistor — Thermistors are thermally sensitive resistors, made of ceramic or metal oxide, whose resistance changes exponentially in correlation to temperature variations. The most common type, the negative temperature coefficient (NTC) thermistor, provides very high resistance at low temperature (i.e., as temperature increases, resistance drops quickly); thus, small changes in temperature are reflected rapidly and accurately (within 0.05°C to 1.5°C). Because NTC thermistors are highly non-linear, if the user needs to measure a wide range of temperatures, an NTC thermistor will require linearization via calibration to several temperature points. The effective operating range is typically –100°C to 325°C. Additionally, the thermistors suffer from self-heating.

- Thermocouple — Unlike a thermistor, a thermocouple consists of two wires of different metals connected at two points. Instead of using resistance, it measures temperature by detecting a change in voltage at the junction of the two metals. Thermocouples are non-linear, requiring conversion when used for temperature control and compensation, and their accuracy is low (0.5°C to 5°C). However, they operate across a wide temperature range and are self-powered.

- Resistance temperature detector (RTD) — An RTD, also known as a resistance thermometer, operates by responding to an increase in resistivity with an increase in temperature. An RTD consists of a pure metal wire wrapped around a ceramic or glass core. The most accurate RTDs are made using platinum, but lower-cost RTDs can be made from nickel or copper. However, nickel and copper versions operate at lower temperature ranges and are not as stable or repeatable as platinum. Platinum RTDs offer a fairly linear output that is highly accurate (0.1°C to 1°C) across –200°C to 850°C. RTDs tend to be the costliest temperature sensors, but they are also highly versatile.

- Semiconductor-based sensor — The introduction of integrated circuit (IC) temperature sensors broadened the scope of sensing beyond traditional capabilities, bringing with them benefits such as lower power consumption, a small footprint, and, for some applications, low device cost. They also simplify the calibration process because IC sensors are calibrated during production testing. The most common varieties are analog output devices, digital interface devices, remote temperature sensors, and temperature switches. Modern semiconductor temperature sensors offer high accuracy and high linearity over an operating range of about –55°C to 150°C.

All of the temperature sensors above are available in discrete form and are not flexible.

Printed electronics up the ante

Printing electronics on flexible substrates using conductive and non-conductive inks instead of lithography is beginning to move into the mainstream as the industry grows increasingly aware of the benefits that this technology can bring to myriad applications. For example, they can marry the functions of a humidity sensor and a temperature sensor within one flexible form factor that can be adjusted to fit a particular shape. In addition, because the technology can pull data from virtually anywhere, these sensors allow users to reap the benefits of big data analysis.

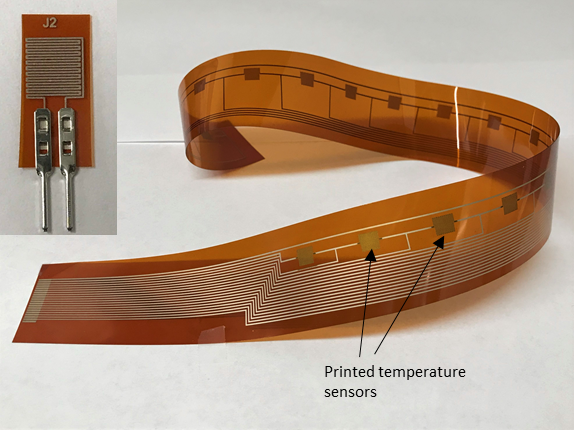

Fig. 1: A printed temperature sensor array with 16 sensors. Inset: A printed temperature sensor.

Printed sensor arrays (Fig. 1 ) offer design, area, and form-factor advantages, and they can be made to accommodate the desired capabilities of a particular sensor type — thermistor, RTD, etc. They are flexible and conformable, unlike conventional sensors, and can be made to accommodate a variety of end-product sizes. In addition, printed sensors offer an advantage of low-cost, scalable manufacturing.

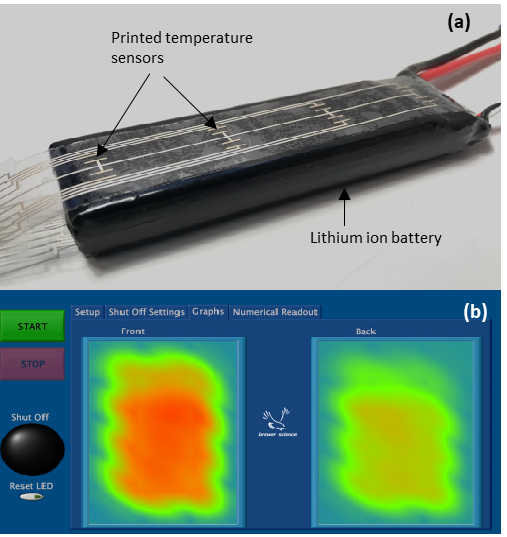

Typically, users look for printed flexible hybrid electronics (FHE) systems when looking to measure temperature in confined spaces with narrow areas where typical silicon sensors can’t fit. For example, a thin array can be printed or attached to a battery pack (Fig. 2 ) to quickly indicate where the batteries may have overheated due to malfunctioning. This capability — which individual, non-flexible sensors cannot perform — is vital for such applications as smartphones and precision equipment.

Fig. 2: a) Printed temperature sensor array attached to front and back of a Li-ion battery; b) Temperature mapping output.

A key benefit of printed electronic sensors when provided in arrays or sensor systems is the ability to measure temperature change simultaneously across multiple points without the need to wire individual sensors, whereas traditional sensors can measure absolute temperature at only a single point. FHE arrays are key for measuring multi-point surface temperature. Multi-point temperature sensors give you the ability to obtain a more accurate reading of what is going on in a given space, as opposed to one-point measurement, which is accurate for that one spot only in the entire room.

Let’s assume that you need to measure the surface temperature of a vessel. While you could measure the temperature at one point and assume that this single point represents the whole, multi-point temperature measurements paint a far more accurate picture. This approach allows the detection of temperature gradients within the vessel to provide better feedback of heating or cooling control.

PE technology allows for measurements in irregular surfaces and tight spaces that are typically found with these vessels. Also, a sensor array for a test apparatus can be printed and quickly applied to numerous test objects, eliminating the need for tedious discrete sensor placement. This not only speeds setup time but allows the sensor array to be placed in the same orientation on every test object.

There are a number of other areas in which being able to measure/monitor temperature changes across multiple points can be not just valuable but truly life-saving. Some examples include:

- Warehouses — Items kept inside these rooms may be damaged by sudden shifts in temperature. An array of sensors can monitor the temperature, activate an alarm in response to undesired temperature conditions, and protect unnecessary loss of inventory. In addition, it protects the warehouse from potential unauthorized access.

- Greenhouses — Say you have a greenhouse full of plants that you are trying to grow in the middle of winter. When you open the door to the room, is their growth affected due to sudden temperature change? If so, how long does it take for them to be affected?

- Server rooms — Heating and cooling are very important when ensuring uptime on servers. Knowing if and when a given zone of the room is getting out of specification is vital to offloading the usage of that stack so that it can cool down as needed.

- Laptops/phones/tablets — Mobile devices today must be assured of not overheating with the constant amount of usage that they are receiving. User harm due to extreme overheating must be scrupulously avoided.

PE addresses challenges

Helping those in the manufacturing sector understand temperature measurement challenges and the benefits afforded by PE arrays is vital. Solutions can be customized for manufacturing equipment to ensure that their specific systems’ temperature management needs are met.

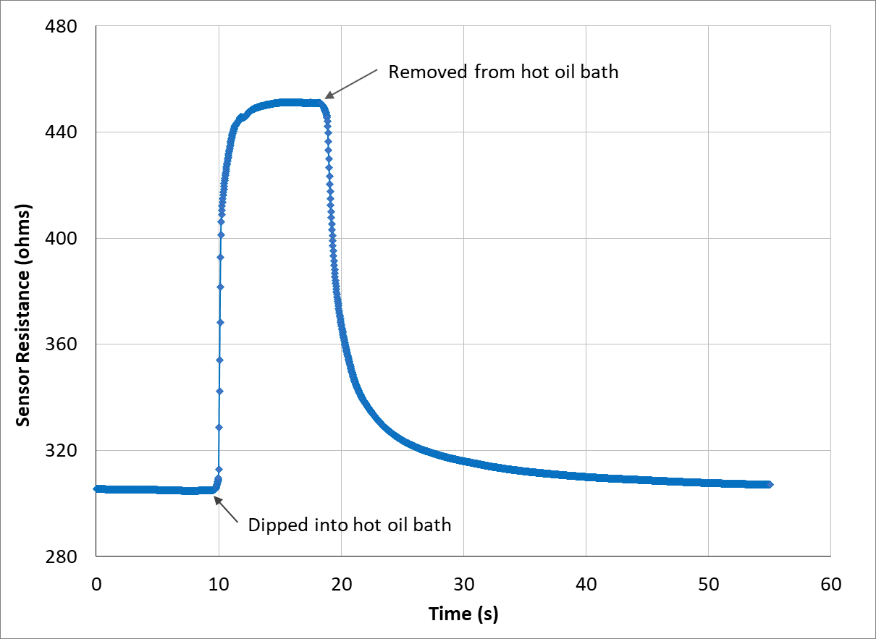

One of the key values for PE temperature arrays is their fast response time. A response time of 175 ms has been observed with manual, hot oil bath tests and may be shorter with more automated testing. A very thin, printed film with almost negligible thermal mass provides the high speed. Having electronics and software built right on the device keeps the response time very quick and enables quicker decisions that could affect the critical objects that the user is trying to keep within such strict temperature constraints.

Fig. 3: Response of a printed temperature sensor when dipped into/out of a hot oil bath (at 160°C).

As with any temperature-sensing device, the user must be aware of any limitations of the PE sensor. These can include working temperature range, accuracy, hysteresis, and long-term drift. Studying the datasheet for each sensing technology will ensure that the sensor is capable of producing the desired results.

With any sensor device, there is no “one size fits all”; selecting the best PE sensor for your application comes down to a make-versus-buy question. It is possible to purchase discrete sensors off the shelf, wire them to a data-acquisition system, place the sensors on the measurement surface, and collect data. For a single test, this can sometimes make sense.

But if the requirement is to replicate the test on multiple devices, this endeavor becomes a time-consuming task. With a custom solution, the actual time constructing the test apparatus can be greatly reduced, and you can obtain a more reproducible result.

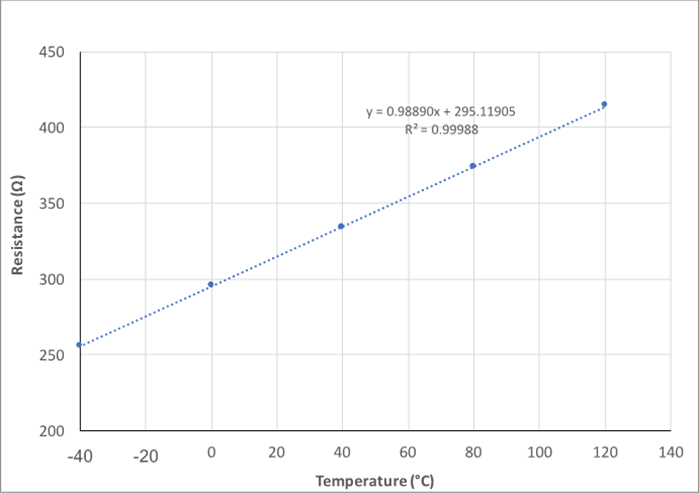

Fig. 4: Extreme linear behavior of a printed, silver-based temperature sensor in the –20°C to 120°C range.

Flexible and printed electronics are becoming a reality after years of research and experimentation. Enhanced performance from printed sensors is achieved through the proper choice of substrate, materials, and manufacturing processes. An accuracy of 0.5°C in the –20°C to 100°C range and a drift (100°C/100 days) of

Advertisement

Learn more about Electronic Products Magazine