Researchers at the Chung-Ang University, South Korea, have developed a new fabrication process for manufacturing flexible supercapacitors on paper. The new process vertically integrates multiple gold electrodes in a single sheet of paper to create high-density energy storage devices.

The new fabrication process yielded a supercapacitor with a low electrical resistance, high foldability and good mechanical strength. Tests demonstrated high energy storage with maximum areal energy and power densities of 13.73 μW-hr-cm-2 and 1.6 mW-cm-2, respectively. The supercapacitor also retained its storage capacity after undergoing 6,000 charge-discharge cycles, said the researchers.

Paper is a promising alternative to plastic and metal foil electrodes used in flexible electronics for powering wearable devices, such as smartwatches, fitness trackers and VR headsets, said the researchers. Plastics have poor adhesion and low durability and metal foils make the devices bulky and less flexible compared with paper, which is flexible, foldable, porous, light and thin, they reported.

Another benefit cited is the randomly distributed fibers of paper that provide more surface area for depositing active electrode material, resulting in “excellent” electrochemical properties.

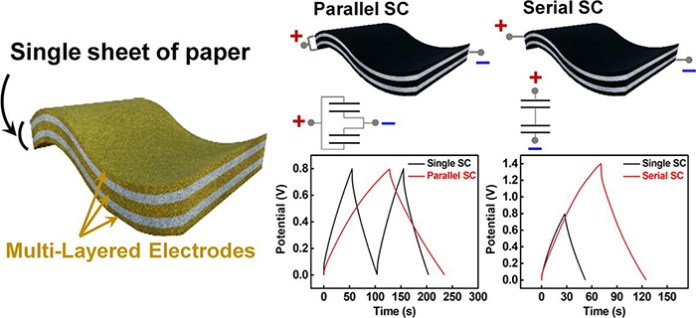

By fabricating multi-layer electrodes that are vertically integrated within the sheet of paper, instead of using multiple stacked sheets for storing energy in existing paper-based supercapacitors, researchers said they were able to avoid mechanical issues caused by the multiple stacked sheets. It also resulted in a supercapacitor with “excellent energy storage.”

The paper-based high energy storage device can be used in both parallel and serial single supercapacitor (SC) configurations without modifying external wires and circuits. The equivalent circuits and electrochemical performance data are shown on the bottom right. (Source: Dr. Inho Nam and Prof. Suk Tai Chang, Chung-Ang University, Korea)

Other drawbacks of existing paper-based supercapacitors using stacked sheets is increased device size and resistance, said researchers, and the they can crease, peel off and slip over each other, which can decrease device performance.

To solve these challenges while maintaining the inherent advantages of a paper-based substrate, researchers at Chung-Ang University, led by Professor Suk Tai Chang and Associate Professor Inho Nam, developed this new fabrication process of vertical integrating multi-layer electrodes within a sheet of paper. Researchers published their results in the Chemical Engineering Journal, which describes the fabrication process using a water-repellent paraffin wax layer, gold nanoparticle and gold enhancement solutions for the gold electrode and a manganese dioxide active electrode material deposited on the gold-paper electrode, which was immersed in a polyvinyl alcohol–sodium sulfate gel electrolyte solution.

The manganese dioxide-gold-paper electrodes were then characterized using a variety of electrochemical measurement techniques, such as cyclic voltammetry, galvanostatic charge and discharge and electrochemical impedance spectroscopy.

“In effect, the multi-layer electrode supercapacitor platform is a super-dense energy storage device that utilizes the two-dimensional paper surface as a three-dimensional scaffold,” said researchers. They believe the findings indicate that future fabrication of paper-based electronics will focus on more multi-layer electrodes.

Advertisement