Researchers from Cornell University have developed a lightweight, stretchable material, similar in consistency to memory foam, which has connected pores so as to allow fluids to be pumped through it.

They believe this polymer foam will significantly advance the capabilities of soft robotics, prosthetic body parts, artificial organs, and more.

The foam starts out as a liquid that gets poured into a mold to create its shape. Because of the pathways for fluids, when air or liquid is pumped through it, the material itself moves; in fact, it can stretch and change its length by 300%.

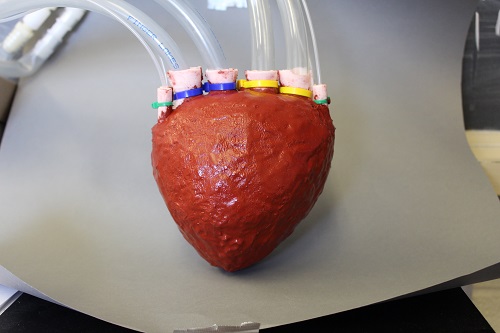

To prove the potential of the material, the team demonstrated a pump they made into a heart, mimicking both its shape and function.

While assigning applications for use in the body is subject to federal approval and testing, the researchers did say they’re pretty close to making prosthetic body parts with the material.

“We are currently pretty far along for making a prosthetic hand this way,” said Rob Shepherd, assistant professor of mechanical and aerospace engineering, and senior author of a paper appearing online and in an upcoming issue of the journal Advanced Materials. Benjamin Mac Murray, a graduate student in Shepherd's lab, is the paper's first author.

In addition to the heart, the team used carbon fiber and silicone on the exterior to create a structure that expands at different rates on the surface. This allowed them to demonstrate making a spherical shape into an egg shape, while still holding its form when inflated.

“This paper was about exploring the effect of porosity on the actuator, but now we would like to make the foam actuators faster and with higher strength, so we can apply more force. We are also focusing on biocompatibility,” Shepherd explained.

A video interview with Shepherd explains the technology a bit further:

The paper is entitled, “Poroelastic Foams for Simple Fabrication of Complex Soft Robots”. You can download it here.

Advertisement