A team of researchers from various education institutions and research facilities has published a first-of-its-kind study that details how structural damage to batteries evolves in real-time, with indications of how this action can spread to neighboring batteries.

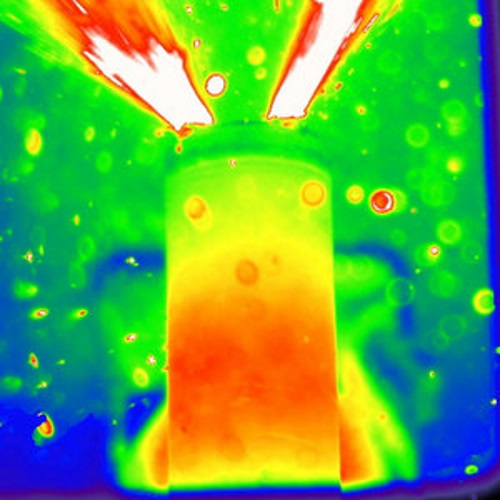

“We combined high energy synchrotron X-rays and thermal imaging to map changes to the internal structure and external temperature of two types of Li-ion batteries as we exposed them to extreme levels of heat,” explained the study’s first author, University College, London PhD student Donal Finegan. “We needed exceptionally high speed imaging to capture 'thermal runaway' — where the battery overheats and can ignite. This was achieved at the ESRF beamline ID15A where 3D images can be captured in fractions of a second thanks to the very high photon flux and high speed imaging detector.”

To date, x-ray-based computed tomography (CT) has been used to analyze battery failure mechanisms post-mortem using static images, and to monitor changes to batteries under normal conditions.

With new monitoring technologies in hand, the team was able to focus on the effects of gas pocket formation, venting, and increasing temperatures on the layers inside two commercial lithium-ion batteries as they exposed the exterior of the battery to temperatures above 250 degrees Celsius.

What they found was that the battery with an internal support pretty much remained intact up until the initiation of thermal runaway; when this instance occurred, the copper material inside the cell melted (indicating temperatures up to 1,000 degrees Celsius). This led to the heat spreading from the inside to the outside of the battery, and very quickly, thermal runaway.

The battery without an internal support, meanwhile, exploded, which caused the entire cap of the battery to detach and its contents to eject. Before thermal runaway took place, the tightly packed core collapsed; when this instance occurs, it increases the risk of severe internal short circuits and damage to neighboring objects.

“Although we only studied two commercial batteries, our results show how useful our method is in tracking battery damage in 3D and in real-time,” said corresponding author, Dr. Paul Shearing. “The destruction we saw is very unlikely to happen under normal conditions as we pushed the batteries a long way to make them fail by exposing them to conditions well outside the recommended safe operating window. This was crucial for us to better understand how battery failure initiates and spreads. Hopefully from using our method, the design of safety features of batteries can be evaluated and improved.”

Looking ahead, Finegan, Shearing, and the rest of the team, which includes scientists, engineers, and researchers, from ESRF The European Synchrotron, Imperial College London and the National Physical Laboratory, will look into what happens with a larger sample size of batteries; in particular, what changes at a microscopic level cause widespread battery failure.

Check out the short clip below to learn more about this study:

Via the University College, London

Advertisement

Learn more about Electronic Products Magazine