For many years, electrical power companies have faced the conundrum of how to balance supply and demand in the most efficient manner.

Demand varies considerably hour-by-hour, even minute-by-minute. In order to meet that demand, utilities must supplement economical base load power plants, which operate continuously at maximum output, with expensive peaking power plants, which spool up and down in response to demand fluctuations.

To complicate matters further, alternative energy sources such as wind and solar are highly variable, but increasingly mandated by law. An efficient, low-cost way of storing energy is needed so that excess production can be saved during periods of low demand, then called into service during periods of peak demand.

Batteries are the preferred choice for small-scale applications such as mobile phones, electric vehicles and server farms, but for grid-scale use, something more is needed. Pumped-storage hydropower has been used for many years, but it's hugely expensive, time-consuming, and suitable sites are increasingly scarce.

Here are five other technologies to watch:

1) Below-Ground Pumped Storage Hydropower

We're all familiar with traditional pumped storage hydropower. Images of massive civil engineering projects spring to mind. In fact, traditional pumped storage hydropower has over 130,000 MW of capacity worldwide, with the current, ahem, “top of the heap” being the Bath County Pumped Storage Station in Virginia, with 3,003 MW capacity. Unfortunately, such projects take years to come to fruition and are incredibly expensive. By the time it's completed in 2019, the Fengning 3,600 MW Pumped Storage Power Station in China will have taken six years to build at a cost of $1.9 billion.

There's more than one way to slice this particular onion, however. Another approach under development – Gravity Power Grid-Scale Electricity Storage – will store water in a 10-meter diameter underground shaft up to 2000 meters deep, topped by a massive piston known as the weight stack. A reversible pump-turbine and motor-generator pumps water down during an associated return pipe during times of excess power, raising the weight stack to store energy.

Admittedly, problems remain to be solved – sealing, for example – but some claim that a single shaft could supply up to 150 MW each for four hours, equating to approximately 1 GW per acre using multiple shafts, at a target cost of $200/kWh.

2) Rail-Based Energy Storage

No place to construct a reservoir at the top of that mountain? How about dragging some 300-ton railroad cars up the slope instead? That's exactly what a rail-based energy storage system does. Enough railroad cars and a long enough incline and you've got yourself grid-scale storage, like the $40M, 50 MW system planned for Pahrump, NV.

Self-propelled cars will travel uphill along a 5-mile track during periods of surplus electricity, powered by high-efficiency motor/generators; they roll back down the 8% grade at up to 20 mph when excess power is required.

The image below shows a scale model undergoing testing. The Pahrump installation will employ 32 vehicles with a catenary system able to absorb or provide 1.5 MW of power per vehicle.

Rail-storage demonstration vehicle

The initial project will be used for load-balancing to even out intermittent power from a neighboring wind farm. Here's a video that shows how it will work.

3) Solar Thermal Storage

Much as solar energy operators wish for more consistent sunshine, solar energy is an intermittent resource. Photovoltaic cell systems convert solar energy directly into electricity and can use any of the storage methods discussed herein. For concentrating solar power (CSP) systems, though, storing excess thermal energy for later use requires a different approach.

Depending on the scale – individual buildings on up – this has led to a wide variety of solutions, with storage media ranging from rock caverns to concrete and underground aquifers.

For a grid application, though, molten salt is a popular method, with an intermediate heat-transfer medium such as water, organic oil or even molten metal for temperatures up to 650ºC. The salt is synthetic, primarily composed of potassium nitrate (KNO3) and sodium nitrite (NaNO2).

4) Compressed-Air Storage (CAES)

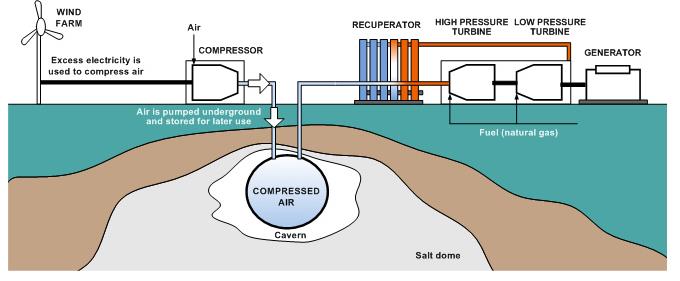

CAES uses off-peak electricity to compress air and store it in a reservoir, either an underground cavern or above-ground pipes or vessels. When electricity is needed, the compressed air is heated, expanded, and directed through a conventional turbine-generator to produce electricity.

Conceptual configuration of a CAES system

Although geological studies have shown much of the U.S. to be potentially suitable for below-ground CAES, above-ground systems are still easier to locate. They are more expensive on a 4 kW basis, however, and typically smaller – up to 15 MW with 2-4 hour discharge times, versus 400 MW and 8-26 hour discharge times.

5) Flywheel Storage: Reinventing the Wheel

A current-generation flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the system, the flywheel's rotational speed is reduced as a consequence of the principle of conservation of energy; adding energy to the system correspondingly results in an increase in the speed of the flywheel.

Such flywheels have carbon-fiber composite rotors, suspended by magnetic bearings, and spinning at speeds from 20,000 to over 50,000 rpm in a vacuum enclosure. Such flywheels can come up to speed in a matter of minutes, reaching their energy capacity much more quickly than some other forms of storage.

This almost instantaneous response (~4ms) has made flywheels attractive for load-balancing systems, which are commercially available. For example, a Beacon Power Flywheel Storage 20 MW plant in Stephentown, NY has been in operation since 2011. In a novel application of flywheel load-balancing, the new Gerald R. Ford class aircraft carrier will use flywheels to accumulate energy from the ship's power supply, for rapid release into the Electromagnetic Aircraft Launch System, replacing venerable (1950s) steam catapult technology.

And The Winner Is…TBD

The jury is still out on which (if any) of these approaches – or one of a number of alternative approaches – will win out. A likely scenario would have multiple solutions being adopted depending on the unique circumstances of each individual situation. Stay tuned…

Contributed by Paul Pickering

Advertisement

Learn more about Electronic Products Magazine