The current power infrastructure is in need of an update for better efficiency, reliability, and safety. Standards organizations and engineers have risen to the challenge, promising to solve many problems with the grid. The so-called “smart grid” embodies many of these solutions. Implementing a smart grid system offers significant design challenges to the engineer, as these systems must have longevity, from not only from a reliability standpoint but also performance and component availability.

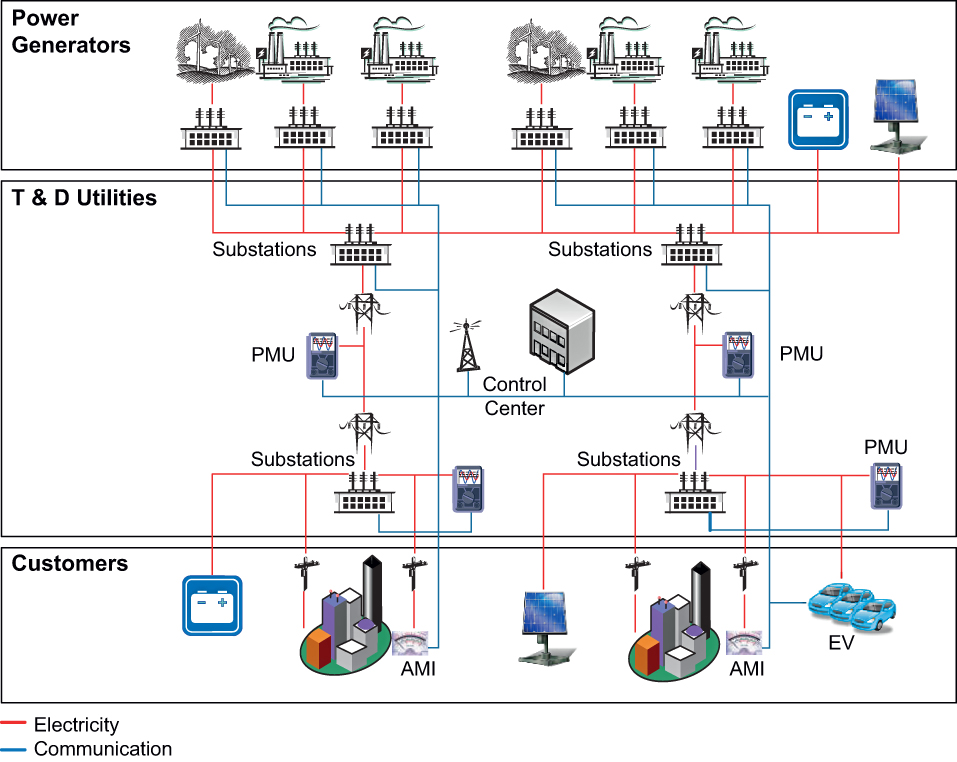

A modern power delivery architecture (see Fig. 1 ) has power generation, transmission and distribution (T&D), and end users. The smart grid differs from legacy systems in many ways, including incorporating renewable energy sources, energy storage, and instrumentation for consumer metering and grid performance analysis. Optimal control of the grid hinges on the presence of extensive communications, the close monitoring and control of grid parameters, and provisions to aid reliability and security.

Fig. 1: Overview of a smart grid.

Standards development

Prior to the mid-1990s, no global power grid standards existed that enabled energy providers to deploy interchangeable equipment. To facilitate improved control and flexibility, the grid needed transforming from a single network of transmission lines to a pair of networks of communications and power distribution. The International Eletrotechnical Commission (IEC) developed a set of core standards that addressed substation architecture, communications, and security, as well as timing and synchronization.

Work began on the IEC 61850 standard, Communication Networks and Systems in Substations , in 1995 with collaboration between the IEC and the American National Standards Institute (ANSI) on a new way of thinking about substations and robust communications networks, as well as a framework to facilitate automation.

Challenges of IEC 61850

Since the inception of IEC 61850 incremental capabilities have been added to broaden the standard's functionality, including areas like hydropower, PV power plants, and distributed energy resources. From an internal substation infrastructure perspective, the standard facilitates interoperability, flexibility, and control with a network of substation equipment communicating over fiber-optic cable. While this network solves a number of problems associated with flexibility and interoperability, it creates new challenges as well. For example, the fiber-optic network (and its accompanying layers of communication hardware and communication stacks) replaces low latency copper wire connections, and to facilitate this IEC 61850 provides support for special messaging that bypasses layers of the communication stack to reduce latency.

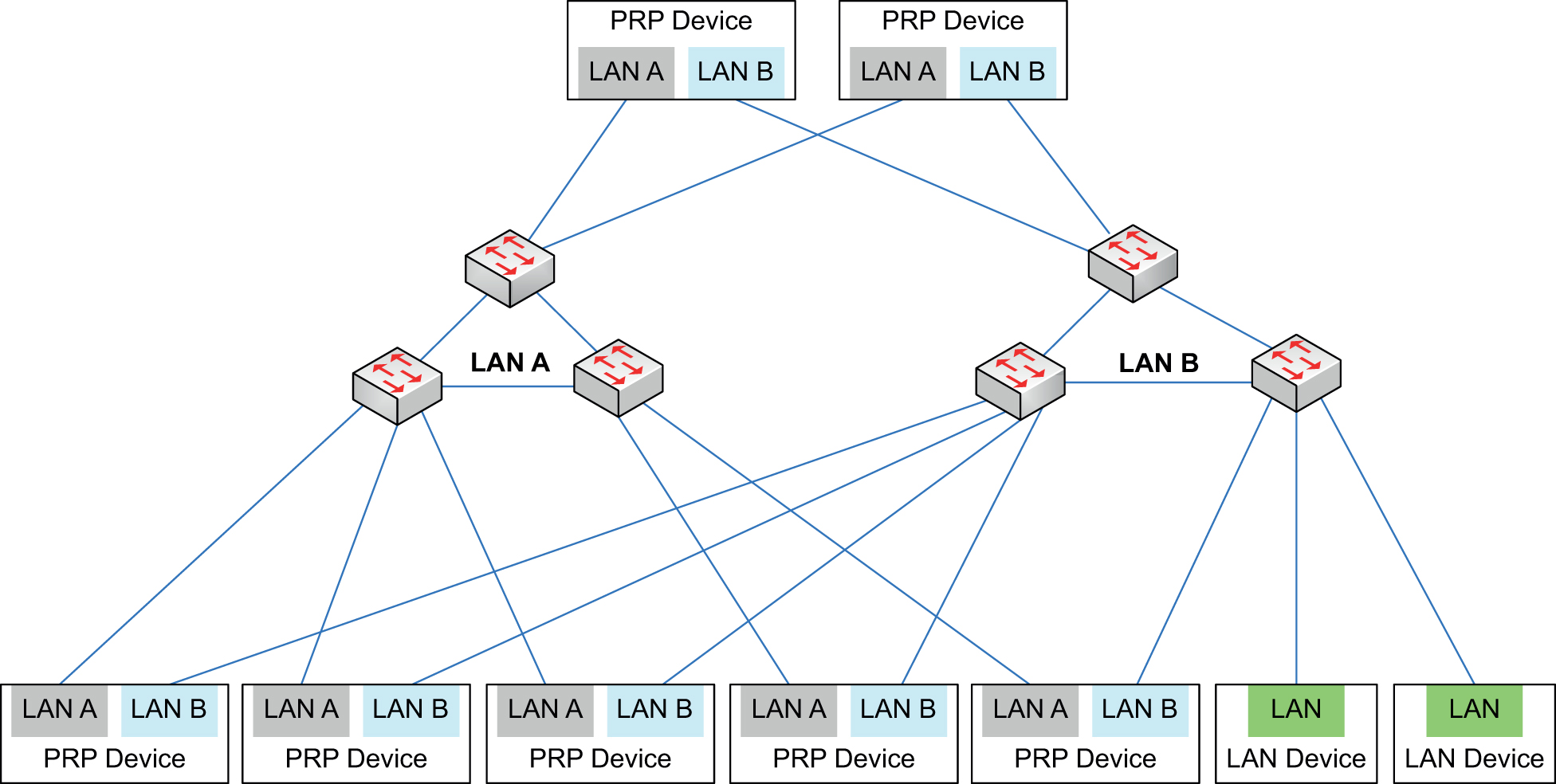

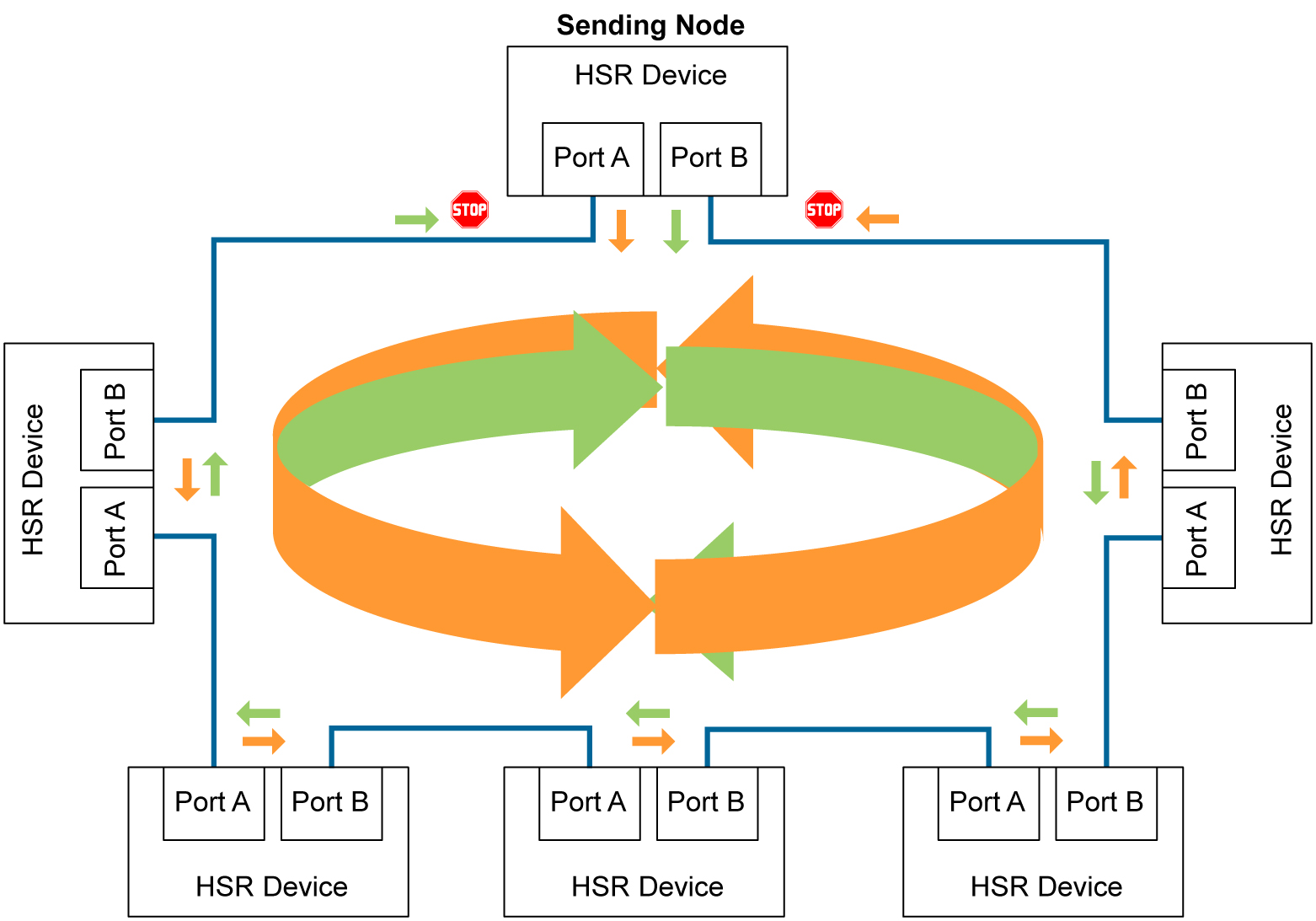

Substation automation standards, like IEC 61850, specify that no single point of failure causes a system malfunction and substation architectures employ redundancy for all mission critical components. Additionally, substation system engineers must meet failure recovery time specifications. IEC 61850 prescribed the use of IEC62439-3, Parallel Redundancy Protocol (PRP) [see Fig. 2 ] and High-Availability Seamless Redundancy (HSR). [see Fig. 3 ]

Fig. 2: Overview of a Parallel Redundancy Protocol (PRP) network.

Fig. 3: Overview of a High-Availability Seamless Redundancy (HSR) network.

Smart-Grid applications for FPGAs and SoCs

In order to make the smart grid “smart,” power grid equipment includes a combination of signal processing, communications management, and dedicated hardware blocks. To accomplish this, systems typically use a DSP, a CPU, and an FPGA. As the capabilities and levels of integration of FPGAs have increased, several smart grid applications have incorporated an FPGA or an SoC to implement all of these blocks, affording better flexibility, reliability, maintainability, and cost. The designs also leverage the device's support for 10/100 and Gigabit Ethernet.

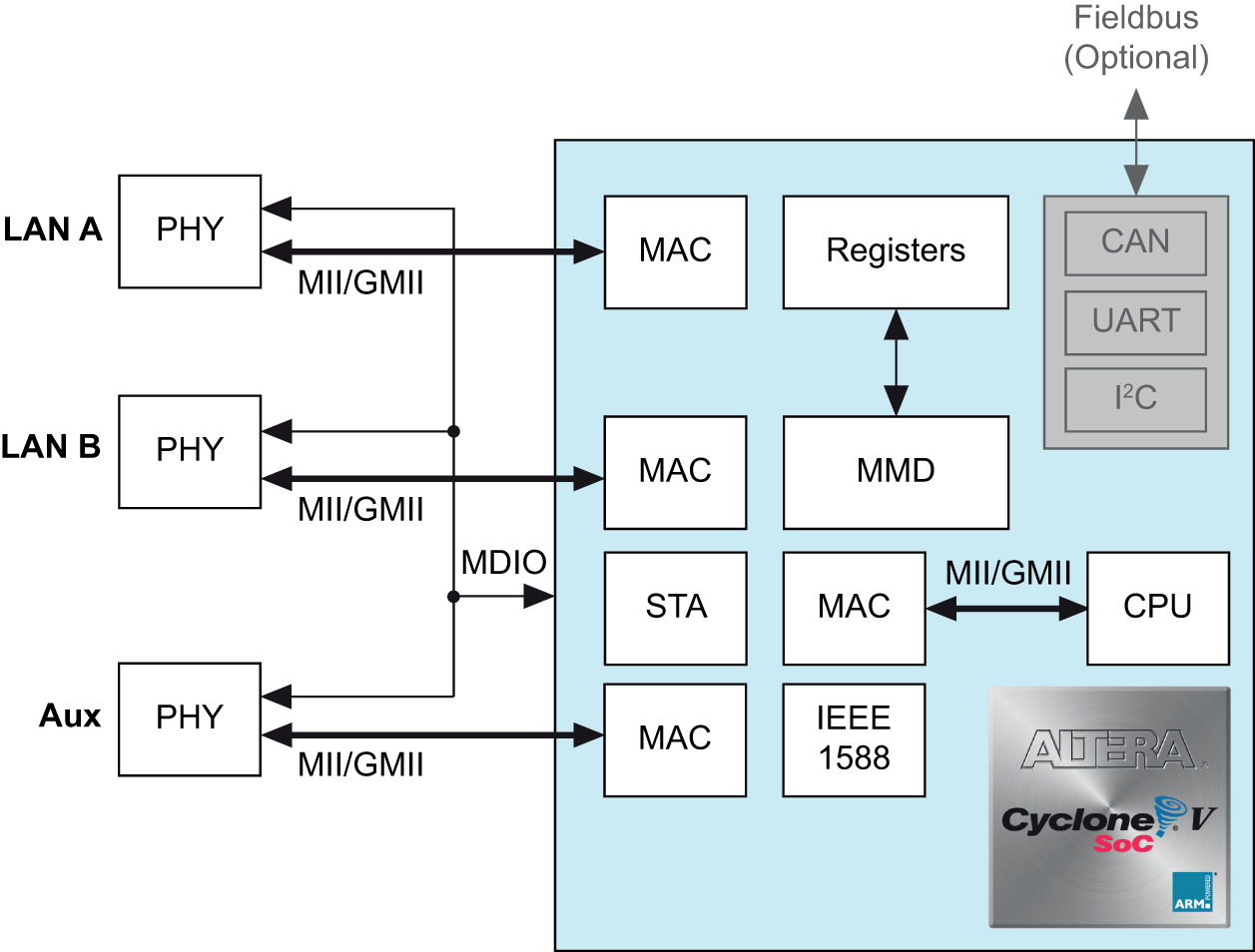

An example of FPGAs being used in a smart-grid applications is the 4-port Ethernet switch with support for HSR, PRP, and IEEE1588-2008 offered by Altera and its smart grid design partner, Flexibilis (see Fig. 4 ). The design is a 4-port switch that is expandable to 8 ports. It supports 10/100/1000 Ethernet, IEC 62439-3-compliant implementations of PRP/HSR, support for IEEE1588-2008, and requires no external memory. Other substation automation equipment (e.g., a transmission relay, etc.) can integrate this implementation with other functions on a Cyclone V SoC.

Fig. 4: PRP/HSR switch architecture.

This SoC FPGA features a dual-core ARM Cortex-A9 processor operating at 800 MHz, and flash, RAM, caches, GPIO, and communications ports commonly used in smart grid systems. The FPGA fabric provides smart-grid developers a variety of benefits, while affords opportunities for integration, performance acceleration, and upgradeability.

Reliability, performance, and time to market

Today's FPGAs and SoCs possess several qualities that help enhance smart grid equipment reliability. High levels of integration reduce the number of components required, thereby enhancing MBTF/FIT rate performance. Features like error correction code (ECC) memory coverage and the use of multiple processors help to insure reliable operation. Some configurations implement a small RISC core within the FPGA fabric, while others simply lock down the level-1 cache of one of the two ARM Cortex-A9 processor cores and employ the dedicated core for diagnostic purposes.

Twenty-eight-nanometer low-power, low-cost SoCs deliver up to 4,000 MIPS performance from the dual-core Cortex-A9 CPU. A NEON coprocessor with double-precision floating point accompanies each core. Each processor includes 32 Kbytes of L1 coherent cache and the cores share 512 Kbytes of L2 cache. Applications that require real-time computational capability often implement hardware acceleration in the FPGA fabric.

An FPGA helps support customer's time to market requirements by available industry-standard CPU cores, state-of-the-art development tools, off-the-shelf IP

Maintainability and longevity

Providing solutions for products that have long product life cycles goes beyond reliability and a commitment to provide the solution for the life of the product. The ability to reconfigure and upgrade products, in production or in the field, is critical, particularly as standards evolve over time. FPGAs help mitigate this problem by providing scalability and reconfigurability to implement product updates that go beyond a simple software change.

Advertisement

Learn more about Altera