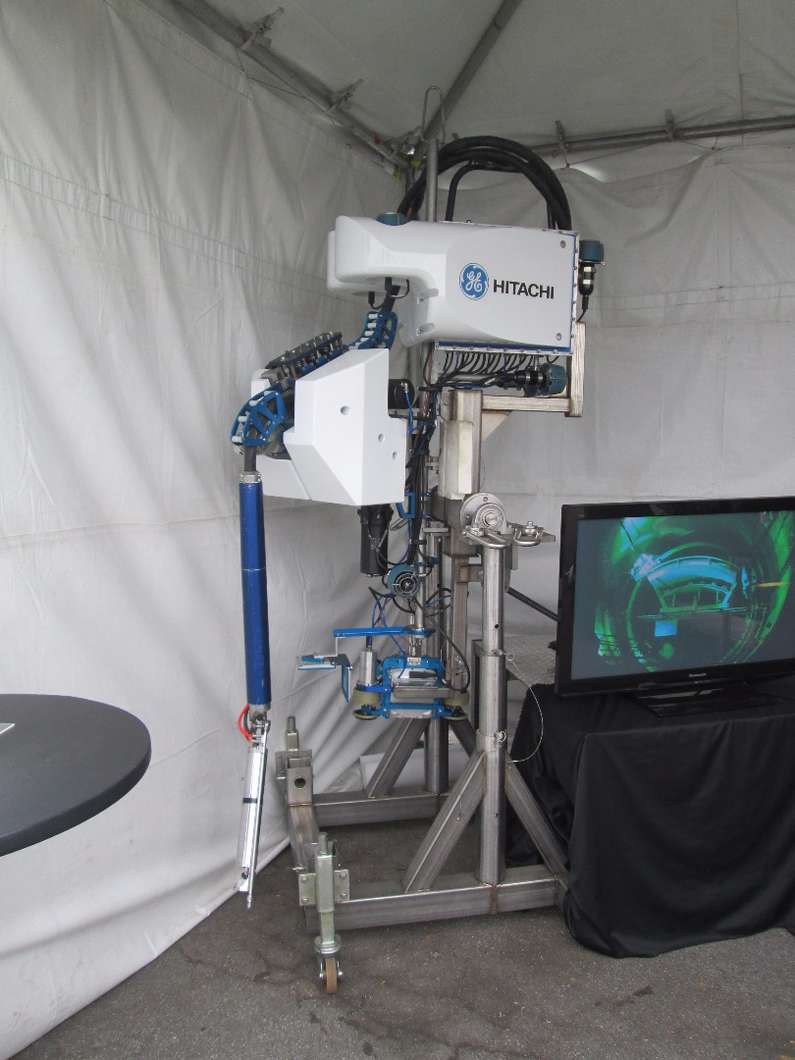

Developed by General Electric Hitachi Nuclear Energy (GEH) and its Boiling Water Reactor (BWR) experts, The Stinger is a robot designed to perform In-Vessel Visual Inspections (IVVI) and maintain the nuclear cores inside of nuclear reactors. Rather than having a team of workers go inside the containment vessel, it offers a safer and more cost-effective method.

To ensure they are working perfectly, nuclear reactors require regular maintenance and inspection as well as periodic cleaning. The inspections are labor intensive and costly, requiring the installation of special bridges just so workers can walk out with poles attached to the instruments needed to properly do the job. This type of work exposes employees to radiation and interrupts inspections constantly because it requires them to remove and change the rods.

The GE Hitachi Stinger replaces the need for a team and a bridge with a large free-swimming robot. Rather than using a track, the robot swims throughout the chamber using an advanced camera and remote positioning technology that is controlled by an operation in a radiation-free area. As an added benefit, the robot may refuel without any interruption.

“Stinger uses a hydro-laser to blast welds with water before it shoots HD video of the weld. This video is then beamed near real-time to Nuclear Regulatory Commission-approved inspectors at our global Center of Excellence in Wilmington, NC, where they are analyzed. Stinger literally replaces eight people standing on the bridge of the reactor lowering cameras and brushes with ropes and pulleys. It is much faster and more accurate than previous methods, while also significantly reducing radiation dose,” said Jerry Dolan, Senior Tooling Manager at GE.

The Stinger has been operating and inspecting nuclear reactors for roughly two years, with hope in the future that this robot can be upgraded to carry out maintenance and repair operations.

Source: Gizmag

Advertisement

Learn more about Electronic Products Magazine