BY VINCENT WANG

Global Product Manager Circuit Protection,

Eaton Electronics Division,

www.eaton.com/electronics

Selecting the right type of circuit protection for a light-emitting-diode (LED) driver can be challenging because system demands vary greatly, depending on the application and power source. However, introducing a few key parameters will help designers dial in on the right component for the job.

Designing new generations of drivers requires knowledge of a wide range of power supply topologies and circuit protection choices. Selecting the right fuses will help engineers optimize lighting durability, lifespan, cost, and form factor.

A single LED typically requires a voltage of 2 to 4 Vdc and constant current to ensure optimal performance and long life. For this reason, all LED lighting solutions need a driver circuit that provides steady voltage and current levels for each LED or LED string. The complexity of the LED driver can range from a very simple 1-W dc/dc converter to a more than 100-W dc/dc or ac/dc converter with power factor correction (PFC).

Older designs rely on simple resistors to limit LED-drive current. A small change in forward voltage results in large forward current in the junction. This will overheat the LED junction. As the junction temperature increases, the forward voltage decreases, producing large current in the junction. This chain of events leads to thermal runaway and LED failure. To eliminate this type of failure, proper current protection in the LED driver circuit is required.

Fig. 1: Block diagram of a complex LED driver.

LEDs are driven by constant current. If the LED junction temperature increases, the forward voltage of the driver decreases, causing the driver to overheat. In this case, the driver itself must be protected against overcurrent and overvoltage to prevent thermal runaway. Without protection, there is a high risk of damaging both the driver and the LED itself. This is a critical reason that circuit protection is mandatory in most markets around the world.

To determine what type of circuit protection is required for a specific LED application, it is important to know where it is needed and the typical operating parameters for the application. Additionally, knowing the difference between primary and secondary overcurrent protection will help designers choose the appropriate fuse selection. Specific application metrics for voltage rating, current rating, temperature de-rating, and interrupting rating also help to determine the component choice.

LED drivers powered by the electrical grid must have overcurrent and short circuit protection. This is driven by UL, IEC, and other safety agency requirements. Typically, time-delay and one-time fuses are used for the driver protection because they can tolerate the high inrush currents when power is initially switched on. Additionally, the fuses can be very small, making them easily integrated into consumer LED light bulbs.

Consider the following parameters for LED driver fuse selection:

1. Voltage rating — For 110- to 230-V grid-powered LED applications, a 250-Vac-rated fuse is needed. Note that select countries demanding 277- or 347-V capable solutions require a higher-rated fuse.

2. Current rating — This is determined by the power output of the driver. Select a fuse rating that is 20% higher than the nominal LED driver current (select 1-A-rated fuse for a driver with 800 mA nominal current).

3. Interrupting rating — This determines the maximum current that the fuse can safely interrupt during short circuits.

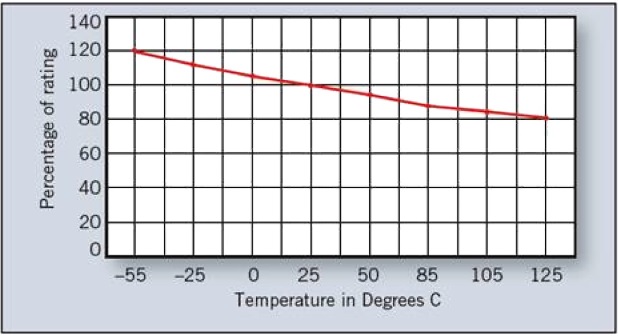

4. Temperature derating — Fuses at higher temperatures open at lower currents. The fuse current rating (See Fig. 2 ) must be derated according to the ambient temperature level. During operation, LEDs generate high levels of heat, which must be conducted away from the printed circuit board. Derating is critical for fuses used close to the light source.

Fig.2: Fuse temperature rating.

5. Melting integral (I2t) — LED drivers tend to draw larger currents at power-up due to the initial charging from input capacitors, so a fuse with larger melting integral (I2t) capability makes an ideal choice.

6. Required agency approvals — Depending on the country of the final lighting device installation, applications may require certification from UL or IEC.

7. Mechanical considerations (size, shape, etc) — LED drivers typically require fuses as small as possible. Chip fuses starting at 0603-size are available for lower-voltage drivers, and for grid-powered drivers, subminiature radial leaded is the popular choice.

Battery-powered LED solutions or subsystems can be protected separately. If only one LED light source is malfunctioning, protecting subsystems is a good way to avoid complete system shutdown.

New applications for LED lighting and illumination technologies are popping up in several industries, including:

• Internet of Things (IoT) — Integrated lighting, heating and security systems, hubs and servers, and smart phones, digital TVs, and appliances.

• Medical instruments, monitors, lighting and emergency systems for hospitals, doctors’ offices, and home health care.

• Automotive and aeronautics — Interior and exterior lighting, headlights, instrumentation and emergency systems for automobiles, as well as roadway and signal lighting.

• Telecommunications — Lighting, energy and emergency controls for server farms, indicators for switches, routers and hubs, lighting and monitoring for enterprise computer systems.

• Industrial — Illumination for handsets, remote equipment, environmental monitors, security systems and industrial sensors, and specialty LED lighting for applications such as food processing plants to refineries.

Eaton has a large selection of circuit protection products to satisfy just about every LED driver circuit requirement. Selecting the ideal fuse to protect against overcurrent and overvoltage is essential to ensuring the long life and reliability of LEDs. The appropriate circuit protection can also help designers optimize driver size and cost for all markets around the world. Visit Eaton’s circuit protection selection guide or www.eaton.com/electronics for additional product information.

Advertisement