Over the past decade, LEDs have had explosive growth in general lighting applications. LEDs offer great advantages over traditional lighting sources that include reliability, long life, reduced power consumption, small size, high efficacy (light delivered per energy consumed), and a high degree of design flexibility. LED manufacturers have been working diligently to increase creative design possibilities for customers, adapting products by incorporating a variety of packaging options. Three major categories worth examining include: (a) discrete components, (b) integrated and general arrays, and (c) packaged solutions such as LED modules.

Discrete High-Power Lighting LEDs

When people first think of lighting-class LEDs, they often think of a discrete high-power (1W or greater) LED. A discrete LED is a single semiconductor diode that has been individually mounted into an appropriate thermal-mechanical package. Ideally, discrete LEDs would be simultaneously very bright and small. Footprint areas on these types of packages have naturally been shrinking over time. Footprints of some commonly used packages in the recent past have been 12 mm2 and 6.3 mm2. An LED package such as the Philips Lumileds LUXEON® Z measures only 2.2 mm2, thus allowing extremely high design-density. LED manufacturers work to provide as much light-output power into the smallest possible package size. The constraining factor in discrete (singular LED) designs is often the thermal resistance (°C/W). LED packages with low thermal resistances allow better transfer of heat away from the die.

Figure 1: An example of a Discrete High-Power Lighting LED, the LUXEON Z platform from Philips Lumileds. Its footprint measures only 1.3 mm x 1.7 mm = 2.2 mm2.

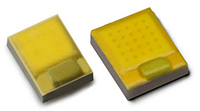

Discrete Mid-Power LEDs: a Category that has Come of Age

In the last couple of years many LED manufacturers have moved towards a new product category called mid-power LEDs, due to the very high number of linear- and distributed-lighting applications. These packages are generally defined as LED packages, consuming somewhere in the 0.2W to 1.0W range (@ 3 VDC x [75mA to 250mA]). Mid-power products are often manufactured in similar footprint sizes to (yet in a different type of package than) their brighter (> 1W) LED brothers. Lower cost and lower total light-output power allow more LEDs per linear meter, thus achieving a smoother and more distributed lighting pattern that replicates the smooth visual output customers are used to.

Arrays

After LED manufacturers developed product lines of discrete LEDs, they quickly came to the conclusion that there would be many advantages to packaging multiple LED dies into a single thermal-mechanical package. One reason for this was the increased need for consistent correlated color temperature (CCT) in general lighting applications. One benefit of an LED array is the ability for the LED manufacturer to control the mixing and matching of LED dies in a very small physical footprint, under the electrical control of one distinct package, and under the optical control of one distinct window and/or lensing arrangement. Common variants of this configuration arose in many packaging arrangements, with the very common approach of one quad-die (4) in a single package.

Integrated (Chip-on-Board) Arrays

As LED manufacturers continued to focus on customer’s end applications, they hit upon another creative idea: integrated arrays or chip-on-board (COB) arrays. This takes the advantages of an array and moves it yet further by mounting the LED die directly onto the circuit board or substrate. This allows a unique packaging arrangement, enabling manufacturers to enclose the entire array with a phosphor-coated window. This ends up as high efficacy, high lumen output light from a single, integrated component. These encapsulated arrays are particularly attractive where high lumen output from a single light source is necessary, such as bay lighting.

Figure 2: LMH modules from Cree are a comprehensive solution.

Comprehensive Solutions, or Modules

LED manufacturers have a goal to sell more LEDs. They recognize that many customers find it hard to take the requisite design steps that are necessary to be successful. To alleviate design issues, many LED manufacturers have continued to move up the customer design chain to offer comprehensive solutions for customers. Solutions often include combining LED, optical, electronic, and mechanical features into a single product called a module[1], a representative example of which is Cree’s LMH product family.

Conclusion

Mouser Electronics is a company dedicated to supplying design engineers and buyers with the newest LED lighting products and leading-edge technologies, combined with unsurpassed customer service and worldwide support. This includes stocking the broadest and deepest assembly of off-the-shelf LEDs, optics, electronics, and mechanical products to support LED lighting designs. For more information on how to select and design LED products, go to www.mouser.com/applications/lighting.

1: An LED module is a unit containing one or more LEDs that is supplied as a light source. Additionally, it may contain further components, e.g. optical, mechanical, electrical, and electronic components, excluding control. Zhaga Standard, http://www.zhagastandard.org/faq/

Advertisement

Learn more about Mouser Electronics