By Cory Jenkins

For some reasons industrial connectors are displacing hard wiring in machine design, manufacturers of railway and transit rolling stock have embraced modular connector design with enthusiasm. After all, a rail or transit vehicle is a machine on steel or rubber wheels. With hard-wiring, it can take many hours of unwiring before maintenance workers can begin to unbolt a bogie in order to replace a malfunctioning traction motor.

With connectors, the power, signal and communications systems can be disconnected and reconnected in minutes. Furthermore, railway and transit vehicles tend to get multiple end-to-end overhauls and system upgrades during their decades-long service life. Consequently, connectors are economical, cost less to install and reduce over-wiring.

Based on Bombardier’s Flexity 2 platform, Toronto’s new Light Rail Trains depend on multiple connectors from HARTING Canada.

That’s an important design consideration where large amounts of wire and cables must fit in tight spaces under floors, or between ceiling panels or sidewalls and as operators add more sophisticated safety and train control technology and passenger information systems on board. Hybrid connectors that accommodate combinations of power, signal and data, even pneumatic lines, are a further time, space, weight and cost saver.

HARTING has made transportation a focus industry. It sells more transportation-specific connectors than any other manufacturer and new connectors are being added on a regular basis. Rail specific connectors are designed to withstand the rigors of rail and transit operations – extreme temperatures, shock and vibration, fluctuating power levels, electromagnetic interference, and more.

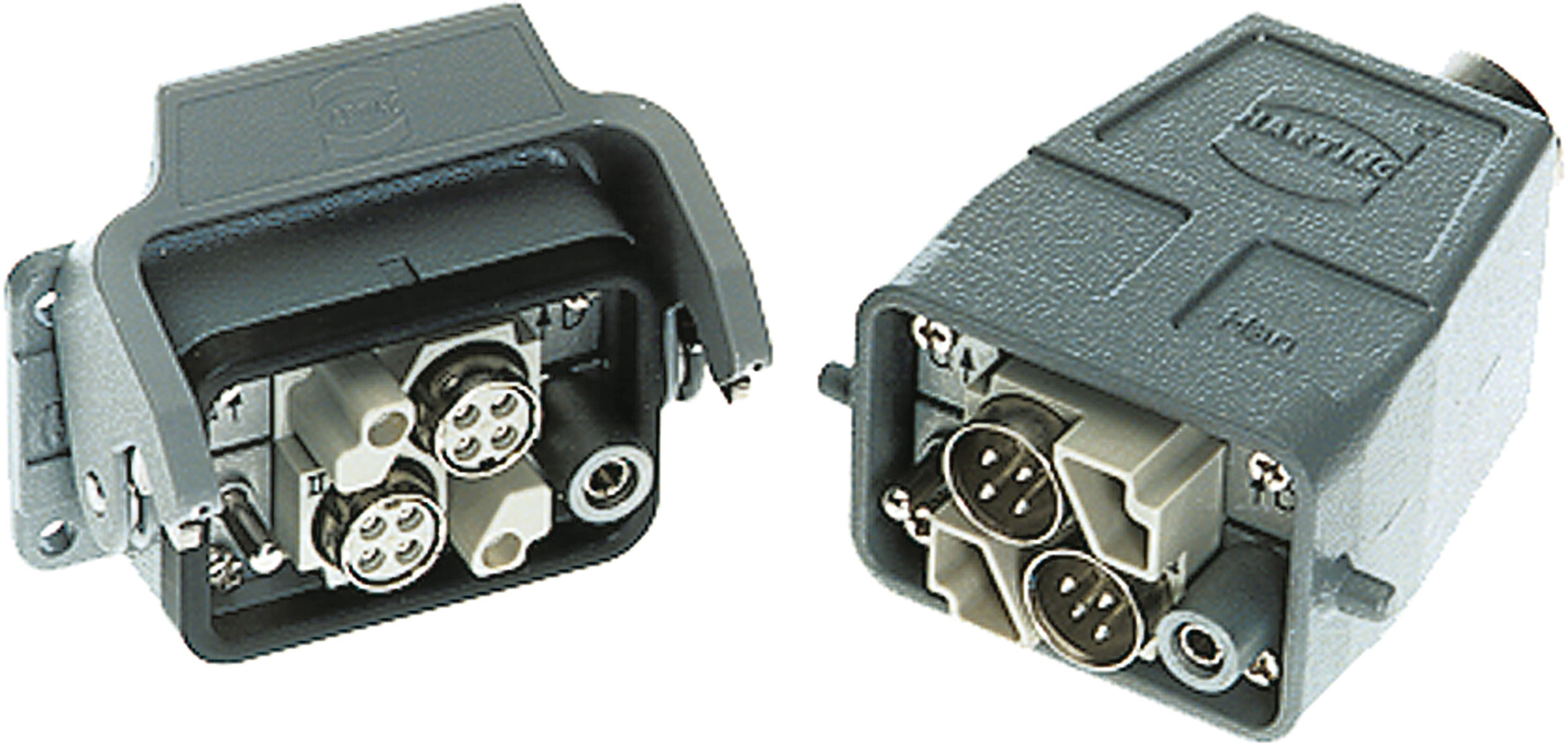

HARTING HAN-modular in an HPR housing are used for power and signal transmission in rugged environments.

In fact, there’s some HARTING connector technology in every new Toronto subway car being built by Bombardier Transportation in Thunder Bay, ON. There will be even more in that city’s light rail vehicles (LRVs) from the same manufac- turer: 204 streetcars to replace the current trams and 182 light rail cars for 52 km of new lines. Those will incorporate HARTING power and signal content as well as communication network and connectivity content.

For HARTING North America, the Toronto LRVs are a marquee order for Canada and a high water mark in building its relationship with Bombardier on this continent. The Toronto LRV fleets will be based on Bombardier’s Flexity 2 100 percent low-floor global platform. Even when modified for local requirements, LRV contracts based on Flexity platforms have a great deal of design commonality.

The Toronto Rocket subway cars and LRVs all use Han-Quintax and M12 crimp connectors. The Han-Quintax is a good example of a product optimized for transportation. It’s a highly shielded, low impedance, 4-pin connector designed to handle sensitive communications with no loss of signal. It is dramatically more efficient to install and maintain than hard-wiring the same network.

HARTING’s Han-Eco connector series used to connect medium voltage cabling systems

The Toronto Trolley LRVs will use Han- Quintax and M12 crimp connectors, but also high IP, all-weather rugged connectors to carry signal power, and communications on some of the company’s latest high performance innovations. For example, the LRVs will incorporate the stainless steel Han-Inox and aluminum die cast connectors for internal and external vehicle applications. In addition, HARTING has developed the Han Megabit module, which is even more compact than Han-Quintax and was designed for rail/transit communications where a Cat 5e Ethernet interface, rated up to 100 megabits, is required.

Spirit of Collaboration

In Europe, HARTING and Bombardier have built a strong relationship. HARTING’s reputation for transportation-specific standard components is part of that, but also for working with Bombardier on developing customized solutions. As an example, HARTING engineers created a special coatless zinc die cast housing for DIN 41612 connections for the front interface to Bombardier’s MITRAC energy saver train control modules.

For Bombardier’s AC TRAXX locomotives, the two companies collaborated on implementing HARTING’s Han-Eco connector series as the standard for connecting medium voltage cabling systems, linking ventilators, pumps and other auxiliary units in the locomotive engine room. Standardizing these functions with Han-Eco connectors made from fiber-glass reinforced, high performance plastic that is lighter in weight and more economical than metal lowered hardware, assembly and warehousing costs.

For new Flexity 2 streetcars in Innsbruck, Austria, HARTING helped implement a new third party passenger infotainment system based on an IP solution it developed for the interconnection of PC-based components that uses HARTING connectors and an eight-port Ethernet switch. Such collaborations don’t just happen in Europe now. At the request of Bombardier engineers in Kingston, Ontario, HARTING customized a communications connector destined for use in the new Sao Paulo monorail program. They liked a particular InduCom interface, but wanted to have additional functionality. As a result of a joint effort by HARTING staff in North America and Europe, the PCB inside the interface was redesigned to meet the customer’s requirement, and a new version of the product was created while also serving an important customer’s requirement.

Cory Jenkins is senior product manager for the Industrial Products Division of HARTING North America.

Advertisement

Learn more about HARTING, Inc. of North America