While graphene has long been heralded as the future of supercapacitors, new research indicates that fibers from hemp plants can contain as much energy and power as graphene itself.

What’s more, its source is a plant, which means it would cost significantly less to manufacture.

For those unfamiliar, supercapacitors are energy storage devices that stand to transform the way future electronics are powered. Where today’s rechargeable batteries sip away at energy over several hours, supercapacitors are able to charge and discharge in a matter of seconds. Convenient, yes, but the problem with the technology as it is currently constituted is that it cannot store nearly as much energy as batteries.

One way researchers have tried to overcome this hurdle is by designing better electrodes, and that’s where news of this discovery becomes relevant. A team of researchers, led by Dr. David Mitlin, has figured out how to make better electrons from hemp fibers, and they’ve proven capable of holding as much energy as its top competitor — graphene.

“Our device's electrochemical performance is on par with or better than graphene-based devices,” Dr. Mitlin explains. “The key advantage is that our electrodes are made from biowaste using a simple process, and therefore, are much cheaper than graphene.”

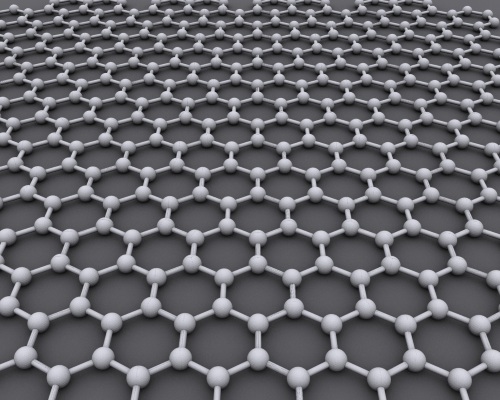

Graphene is widely accepted as the miracle material that will one day lead to more energy efficient technologies. Some of the areas in which it is being applied include building solar cells, water filtration systems, touchscreen technology, batteries, and supercapacitors. The reason why development with the material has somewhat slowed in recent years is the fact that it is expensive to produce.

In an attempt to find an alternative solution, Dr. Miltin and his group sought to create graphene-like carbons from hemp bast fibers. These fibers come from the inner bark, and are typically thrown away by companies that use the plant for things like clothing, construction material, furniture, and other products.

Researchers have always believed there to be more value to the hemp bast; it was just a matter of figuring out how best to process the material.

“We've pretty much figured out the secret sauce of it,” says Dr. Mitlin. “The trick is to really understand the structure of a starter material and to tune how it's processed to give you what would rightfully be called amazing properties.”

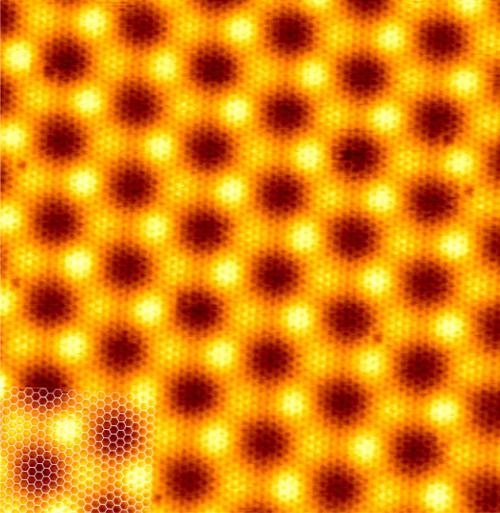

Specifically, the group heated the fibers for 24 hours at approximately 350°F. They then blasted the material with more intense heat, which resulted in the exfoliation of carbon nanosheets.

Using this technique, Dr. Mitlin’s group built supercapacitors using the hemp-derived carbons as electrodes and an ionic liquid as the electrolyte. When fully assembled, the technology performed better than commercial supercapacitors both in regards to energy density as well as the range of temperatures over which it could operate.

In terms of actual numbers, the hemp-based supercapacitors were able to yield energy densities as high as 12 watt-hours per kilogram, which is somewhere between two and three times higher than technologies now on the market. Dr. Mitlin’s devices were also able to operate over a much wider temperature range, from freezing to more than 200°F.

“We're past the proof-of-principle stage for the fully functional supercapacitor,” he says. “Now we're gearing up for small-scale manufacturing.”

Dr. Mitlin and his colleagues published their paper under the title “Interconnected carbon nanosheets derived from hemp for ultrafast supercapacitors with high energy.” They will present their findings at the 248th National Meeting & Exposition of the American Chemical Society.

Story via phys.org

Advertisement

Learn more about Electronic Products Magazine