By Heather Hamilton, contributing writer

Researchers at the University of Tokyo’s Graduate School of Engineering in partnership with Dai Nippon Printing recently unveiled an elastic display designed to fit tightly over the skin to show the waveform of an electrocardiogram. The wearable, which contains an on-skin electrode sensor and wireless communication module, transmits data to the cloud. The team hopes to reduce the burden on patients and family members who utilize nursing care and improve the quality of life by enhancing the availability and accessibility of information.

Doctors can see the electrocardiograms on a screen in real time or they can be stored for later access. Right now, the device has the potential to improve the quality of information from patients that are elderly or otherwise unable to operate more difficult and intrusive devices. For self-care or at-home-care patients, the promise of more accurate, easier-to-obtain information is significant.

Basically, the skin product turns a patient’s actual skin into a tiny screen that can broadcast (or send to the cloud) their heartbeat, allowing medical professionals to see results in the moment.

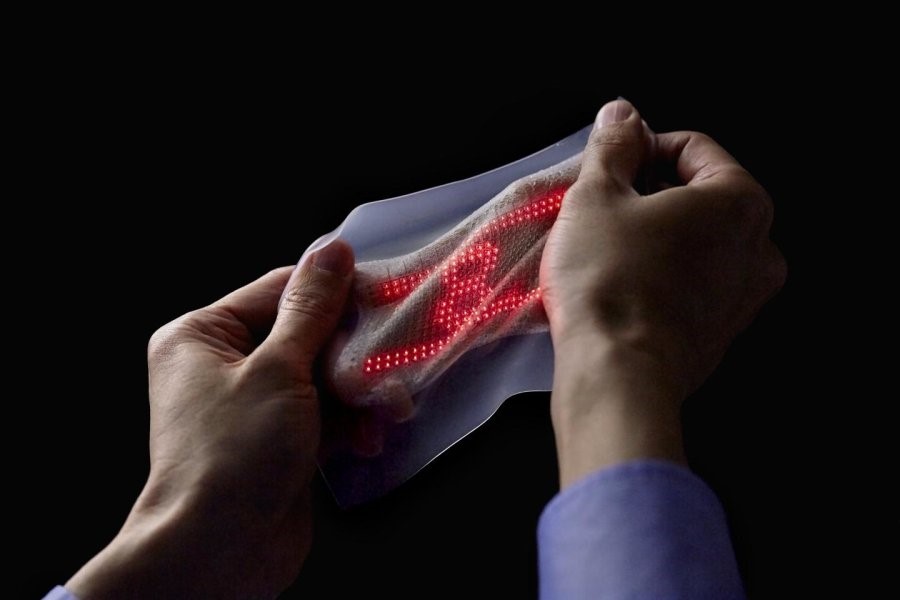

The electronic skin is made from a 16 x 24 cluster of microLEDs and wiring on a rubber sheet. The wiring is stretchable (by up to 45% of its original length), which helps make the material more like actual, human skin.

“Our skin display exhibits simple graphics with motion,” says professor Takao Someya, the project’s lead researcher. “Because it is made from thin and soft materials, it can be deformed freely.”

Among a host of electronic skin competitors, this particular one stands out because it claims to be the most durable because it stretches where the hard and soft materials meet. It is stable in air and can be worn for a week at a time without irritating the skin. In fact, researchers claim that not a single pixel failed in the matrix display when it was attached to and moving with the skin.

In a press release, the team notes that they achieved the electronic skin product by using methods often used in the mass production of other electronics. By screen-printing silver wiring and using a chip mounter to mount the LEDs on the rubber sheet, they will likely be able to accelerate the commercialization of the display and minimize production costs.

Dai Nippon Printing has said that they’re planning to introduce the skin display to market within three years, assuming that they’re able to improve the reliability of the stretchable devices through improvements to structure, a production process better suited for high integration, and a few other technical challenges, which include the coverage of large areas.

Sources: Eureka Alert

Image Source: 2018 Takao Someya Research Group

Advertisement

Learn more about Electronic Products Magazine