By Krunal Maniar, business development manager, Texas Instruments

Drivers in the market for a new vehicle are actively seeking quieter cars that provide a superior communication experience, both among passengers as well as to the outside world. Cars are much quieter as they become more electric; however, passengers in these quieter cars, especially at higher speeds, would typically hear more noise from outside than they would in a noisy, internal combustion engine car.

With the quest to reduce cabin noise even further, advanced techniques using microphones, amplifiers, loudspeakers, and advanced digital signal processing are used to enable background-noise reduction, clear voice communication between passengers, and emergency and high-fidelity hands-free voice calling.

Introduction to active noise cancellation

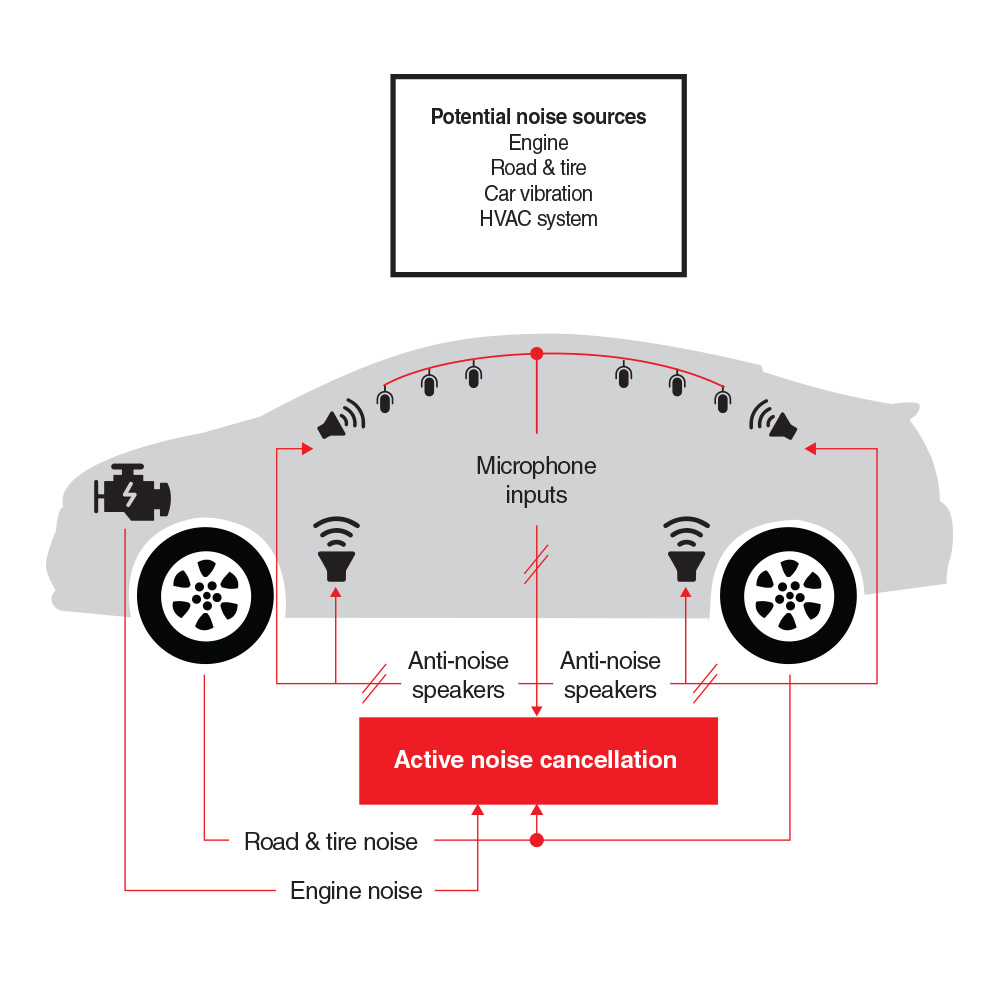

Conventional noise-cancellation techniques such as passive insulation and specialized tires make vehicles heavier and reduce fuel efficiency. As shown in Fig. 1 , active noise cancellation (ANC) methods can achieve the same benefits with reduced overall weight compared to passive insulation methods and without affecting fuel efficiency.

An ANC system works by strategically placing two to six microphones throughout the interior cabin of a vehicle. These microphones measure interior noise and transmit audio data to an audio subsystem that, in turn, puts out an anti-audio signal to built-in loudspeakers. Because these are the same loudspeakers used for audio playback applications, the addition of an ANC system comes at a relatively low additional cost.

Fig. 1: An ANC system uses microphones and built-in loudspeakers to reduce in-cabin noise.

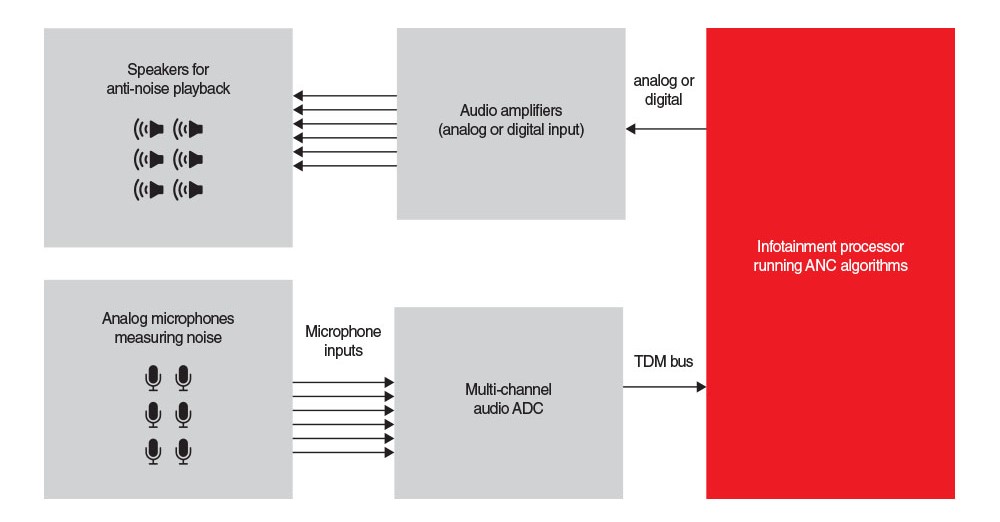

The ANC system for entry-level cars uses two to four microphones, whereas high-end cars use as many as six microphones. Fig. 2 shows a typical ANC implementation.

Fig. 2: Block diagram shows how the microphone signals are combined to generate an anti-noise playback signal.

Several strategically placed microphones inside the car cabin capture noise from sources such as the engine, road and tire contact, wind, structural vibrations, and the heating, ventilation, and air-conditioning system.

An audio analog-to-digital converter (ADC) digitizes the audio signal coming from the microphone array and sends the digitized output to the applications processor through a time division multiplexing (TDM) bus.

The applications processor implements the feedback ANC algorithm and produces an anti-noise signal of equal and opposite amplitude to the measured audio noise. This anti-noise signal is played back on the already-available speaker system, resulting in the cancellation of active surrounding noise.

Similar to an ANC system, in-cabin communication (ICC) and hands-free voice beamforming systems that enhance the communication experience between passengers, as well as to the outside world, require a multi-microphone and multi-speaker system. All these systems coexist and effectively communicate with each other to create an enhanced experience inside the cabin. Depending on system requirements, vehicle size, and luxury level (low, middle, and high end), OEMs use different numbers of microphones for each of these applications.

Key design considerations

ANC systems use two to six microphones. These microphones need to be biased to the recommended bias voltage as provided by the microphone manufacturer. They also need to be diagnosed for different fault conditions such as:

- Microphone signal shorted to ground

- Microphone signal shorted to MICBIAS

- Microphone signal is open

- Microphone differential signals shorted with each other

- Microphone signal shorted to the battery voltage (VBAT )

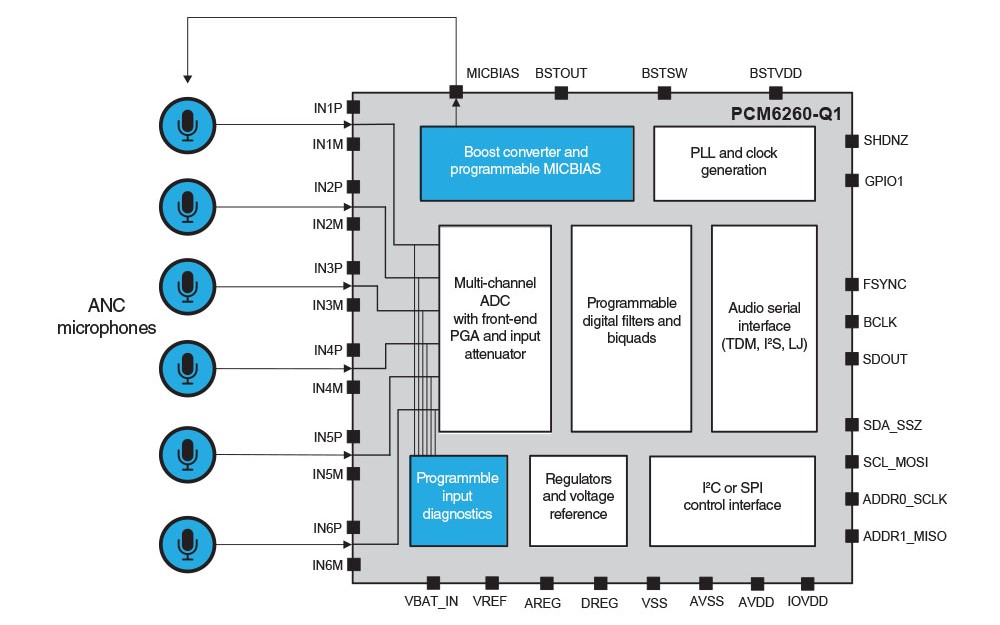

As an example, programmable microphone bias and the comprehensive fault diagnostics features available in the audio ADC PCM6260-Q1 from Texas Instruments (TI) allow the user to accommodate both of these functionalities in a very cost- and size-optimized manner.

The device supports a fully programmable, microphone-input, DC-fault diagnostic feature for direct-coupled or DC-coupled inputs while simultaneously recording the microphone. These faults use programmable thresholds. The individual faults and the individual channels can be individually enabled or disabled. In the event of a diagnosed fault, an interrupt is sent to the interrupt pin. Reading back the status registers can provide other details such as the type of fault, as well as the channel for which the fault occurred.

Additionally, this device integrates a built-in low-noise, programmable, high-voltage microphone bias pin for biasing analog microphones from 5 V to 9 V. The integrated bias amplifier supports up to 80 mA of load current that can be used for multiple microphones and has been designed to provide a high power-supply rejection ratio, low noise, and programmable bias voltages to enable fine-tuning of the biasing for specific microphone combinations.

For the two to six microphones needed in an ANC system, the PCM6260-Q1 is one of a family of audio ADCs that are available with two (PCM6020-Q1), four (PCM6240-Q1, PCM6340-Q1), six (PCM6260-Q1, PCM6360-Q1), and eight (PCM6480-Q1) channels. Fig. 3 is an application block diagram for a six-microphone ANC system with the PCM6260-Q1.

Fig. 3: PCM6260-Q1 is used to implement a six-microphone ANC system.

What are the future trends for implementing audio in ANC systems?

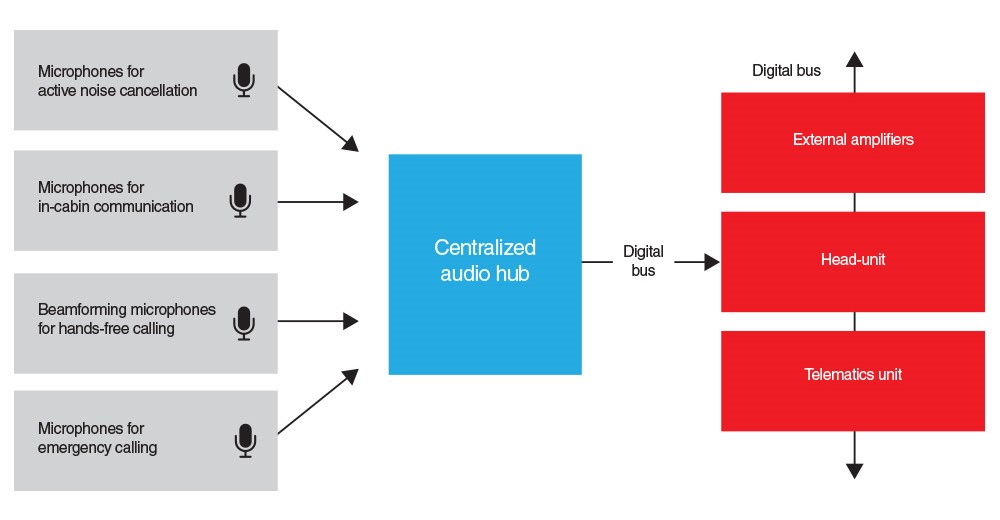

Looking ahead to future implementations, some OEMs are also considering an audio hub, as shown in Fig. 4 .

Fig. 4: Audio hub module

The audio hub would take in audio signals from the ANC, ICC, eCall, and hands-free microphone systems. It would then digitize and accumulate the audio signals and send the digitized signals to the respective audio subsystem for further processing.

While the audio hub is meant to support an increasing number of microphone inputs, an audio ADC such as the PCM6260-Q1 would serve such an architecture well by allowing up to 24 microphones to share the same control I2 C bus and TDM bus.

As trends in ANC, ICC, and hands-free beamforming continue to evolve, the audio hub will reduce microphone routing and implementation complexity as well as reduce the cost associated with microphone cables.

About the author

Krunal Maniar is a business development manager for precision ADCs at Texas Instruments. Prior to this role, Krunal was the lead validation and test engineer at TI for high-performance delta-sigma ADCs. Krunal earned his master’s in electrical engineering from Arizona State University.

Advertisement

Learn more about Electronic Products MagazineTexas Instruments