Robots are becoming smarter. In the factory, industrial robots have to sense the presence of human workers to avoid possible injuries to them. They should also be able to detect abnormal situations, such as excessive vibration, that could cause damage. Service robots that are either safe-guarding a warehouse or acting as a telepresence device for a remote person need to navigate autonomously. Just like we use our natural senses, robots need sensor technologies to help them become smarter, safer to use, and more useful to humans.

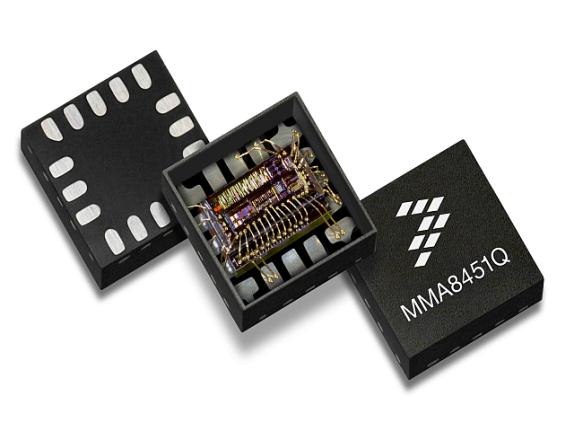

MEMS sensors are amazing little devices, just a few square millimeters in size and typically packed with two dice. One is the sensor die itself, typically a MEMS device providing, say, motion or pressure information, but it could also be a magnetic solid state sensor. The other die provides the signal-processing function needed to convert the very small analog signal coming from the sensor into usable information that can be communicated over some serial bus (see Fig. 1 ).

Fig. 1: The MMA8451Q is a smart low-power, three-axis capacitive accelerometer that can be used for applications such as eCompass, orientation direction, activity analysis, and motion detection .

The small size and affordable price of these sensors make them ideal pieces of technology for use in robots. They are small and inexpensive because they are sold in the hundreds of millions into smartphone and other consumer gaming applications. They also consume very little power. For instance, an accelerometer sensor typically consumes less than 10 µA operating from a 2- or 3-V power supply; power consumption will usually be a trade-off between the frequency and the accuracy of the desired point of operation. Lower power schemes — below 1 µA — can also be achieved with specialized sensors designed to operate as a movement trigger or tamper detection unit. The fast wake-up and shut down mechanisms they provide are then the most important parameters influencing power consumption. Power savings techniques will vary depending on the application needs and the requested frequency for taking data points.

For space-constrained applications, robot designers can also choose an accelerometer with built-in microcontrollers and memory to build very small systems with customized software (see Fig. 2 ). These sensors are frequently referred to as sensor hubs, since they also often offer the ability to connect additional sensors without needing additional processors. The Freescale Xtrinsic MMA9550L, for instance, offers a 3 x 3-mm three-axis accelerometer and a 32-bit microcontroller with 14 Kbytes of flash and 1.5 Kbytes of RAM. This sensor and others like it could be useful when the sensors would need to be placed in robot end-tips or arm segments, where space is very tight. Another application could be to design very small robotic systems that could be worn, or even a robotic capsule that could be swallowed for endoscopic medical applications (see Fig. 2 ).

Fig. 2: For space-constrained applications, smaller chips or those with built-in microcontrollers are most useful. This chip, the Kinetis KL02, is so small it’s considered swallowable .

The on-board memory and microcontroller in such device could also be used to implement a sensor communication protocol, such as IO-Link. This increasingly popular sensor network protocol requires around 10 Kbytes of memory and could therefore be integrated in this small form factor, enabling new sensor-node designs and form factors.

Synergy

The next step in sensor system design is to use all the “senses” that you can and should have to achieve the desired robotic performance. This is often referred to as sensor fusion, which allows a sensor system to capitalize on the individual sensors’ strengths to produce more accurate data and a better product design.

For example, an electronic compass gives north/south direction. While one might think a magnetic sensor reading the earth’s magnetic field is enough to deliver stable information, this is actually not the case. Magnetic sensors’ output values will change when the sensor is titled up or down. So a linear-motion sensor (accelerometer) needs to be added to sense tilt movement and compensate the magnetic sensor reading using some trigonometric algorithm. A good electronic compass will be designed with both these sensors. An even better system would encompass these sensors integrated into the same package, resulting in a smaller sensor. For example, the Freescale Xtrinsic FXOS8700CQ offers geomagnetic field measurement with tilt compensation in only 3 x 3 x 1.2-mm package size, providing an easy way to integrate an X/Y orientation into any robotic system.

Another example: indoor location systems that can’t rely on GPS signals use WiFi base station triangulation to locate a user’s smartphone inside a shopping mall or airport (see Fig. 3 ). The precision of this system can be enhanced by adding a very small altimeter sensor, such as the Freescale Xtrinsic MPL3115. With a relative altitude resolution of about 30 cm (1 ft), this sensor will easily detect the phone traveling up or down a floor within the building. This simple information can be very useful to simplify or validate the results of the complex triangulation algorithm. A surveillance robot watching an outdoor facility will also need to know if it is moving up or down floors, which will have an impact on its speed or power consumption; this is important data to take into account for its autonomy duration.

Fig. 3: Indoor location systems that can’t rely on GPS signals use WiFi base station triangulation to locate a user’s smartphone inside a shopping mall or airport to provide relevant information. This approach could be used in robots that must operate in similar non-GPS environments.

Another sensor-fusion function you can implement with an altimeter is shock detection. Autonomous robots that move around a warehouse floor or a hospital hall are designed not to bump into people or objects, but in case this happens, the robot needs to be able to detect the collision. Accelerometers can be programmed to detect vibrations with a specific “bumping” signature, but that it is not foolproof. By adding a pressure sensor coupled with some pneumatic belt around the robot, the system has two different sources of sensing information, improving the accuracy of “bumping event” detection.

More fusion

Still another great technology to help autonomous robots navigate and avoid obstacles is image recognition. Vision systems exist today that can recognize shapes, objects, or even human faces. A moving robot will want to create a real-time 3D map of its surroundings to determine any possible obstacles.

A camera will work as long as the visibility or light conditions are good enough for the image sensor to capture enough relevant data. But in outdoor conditions, vision system capability could be limited by snow, fog, or other weather incidents. Radar sensing technology, though not MEMS-based, is then the appropriate sensor fusion addition. Combining video image processing information with distance and speed radar data could help the smart navigation algorithm to compute more accurate data and build a better 3D map of the robot surroundings.

Radar systems have been designed primarily for automotive applications, but are easily applied in other systems. They operate in the 77-GHz frequency band and provide very accurate distance and speed information from distances of a few hundred meters to close proximity. Traditional systems use discrete RF circuitry and RF modules with rotating antenna to provide the 3D mapping information. But with a high-performance silicon-germanium (SiGe) process using super-fast transistors with a transition frequency (fT ) of 150 GHz, discrete RF functionality can be integrated into chips. This enables the design of cost-efficient multiband RF chipset solutions driving multichannel patch antennas that can be used to eliminate the need for rotating antennas. This high-performance RF process and design expertise, together with digital beam-forming techniques and signal processing algorithms, brings radar systems to a size and cost compatible with high-volume automotive applications and robotics requirements.

These are only a few examples of sensing technologies that robot designers can leverage to enhance their system designs. Many sensors are designed for

consumer smartphone or automotive applications, which require high volume, high quality, and low cost. With appropriate sensor-fusion algorithms, these low-cost sensors can enable new design possibilities for robots.

Advertisement

Learn more about Freescale Semiconductor