By Jean-Jacques DeLisle, contributing writer

In many modern aviation, naval ship, nuclear facilities, and industrial projects, confined spaces and hazardous environments are very common. Traditionally, many of these applications have required specially trained and expensively equipped technicians to maneuver complex machinery and inspection equipment into awkward and dangerous spaces. Though there are some societal concerns of robots replacing human workers, in many of these dangerous instances, a robot is a safer and more efficient solution.

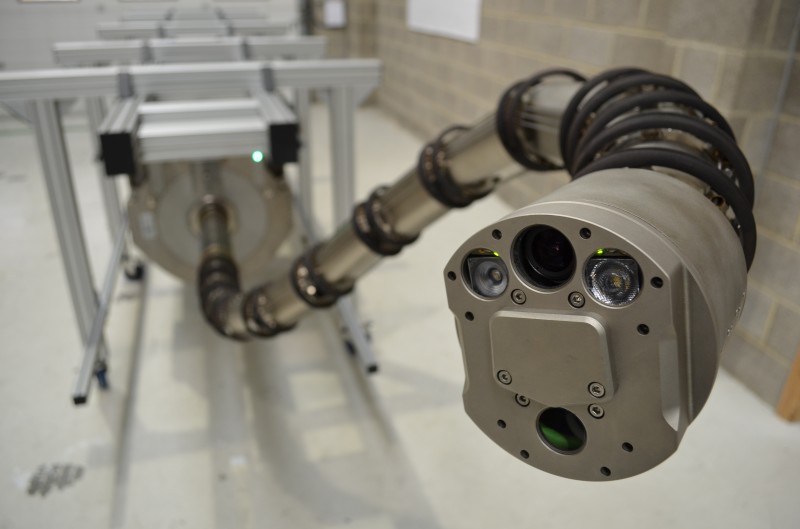

An exciting innovation that meets these needs is the snake-arm robot from OC Robotics, a U.K.-based snake robotics manufacturer. With the help of a human operator, advanced control software, and a suite of inspection, vision, and manipulation tools, a snake-arm robot is able to follow the path that the operator steers the snake to in order to perform in a variety of confined and dangerous spaces. These snake-arm robots are able to cover articulated lengths up to 3.1 m and rigid extension lengths to 5 m, with 24 degrees of freedom for 12 joints and a total cumulative bend of 225 degrees.

A Series II, X125 System from OC Robotics seen unsleeved and equipped with an inspection camera and light tools. Image source: OC Robotics.

Though this may sound awesome, and creepy, they’re actually potentially very useful robotic devices. For example, during Hong Kong’s below-sea-level road-tunnel planning in 2012, resident engineers had to devise a method to ensure that the large boring machine, with many blades and massive metal shield, was within operation and safety standards. This required an inspection technician to crawl between the boring machine and the recently bored rock and perform blade sharpness and shield integrity inspections while lugging all of the necessary equipment and keeping an eye on hazards.

Today’s solution leverages a snake-arm robot with a laser measuring system to gauge the sharpness of the blades and a high-power water jet used to clean the boring machine head. “This is faster and easier, and it keeps people safe,” Andrew Graham, OC Robotics co-founder, told GE.

The robot’s dexterity and skills impressed engineers from GE Aviation such that it acquired OC Robotics last summer. The company believes that snake-arm robots will be useful for jet engine maintenance, allowing workers to do as much work with the engine still on the wing as possible.

OC Robotics’ snake- arm robots and similar robotics solutions could handle many of the tasks that are too dangerous or impossible for human workers to perform. Image source: OC Robotics.

Another example of the usefulness of such robotics and their ability to protect human workers is the LaserSnake variation, which is an integrated snake-arm robot with a 5-kW laser cutter protruding from the head of the snake. Far removed from an evil villian’s hero-torturing robot, the LaserSnake was previously used to disassemble radioactive parts or a nuclear fuel processing facility, namely a 5-ton and 1.5-inch-thick stainless steel tank. The laser-cutter-equipped snake-arm robot was able to cut the tank into roughly 40-pound pieces, which were then more easily removed. Without the LaserSnake, this operation would have required many technicians, all donning $2,500 single-use protective suits, years of claustrophobic labor to extract.

Though many articles discuss how the new robot economy is threatening jobs and could eventually cause labor shortages, there are many applications that are unarguably much safer for human technicians to be performed by such cutting-edge robotic systems. These types of innovative robotics may also enable a new workforce of robot operators, who benefit from higher pay and safer working conditions than technicians who face daily hazardous conditions.

Advertisement

Learn more about Electronic Products Magazine