With new 3D printers entering the market on an almost monthly basis, the web is so caught up reporting on these devices that no one has actually taken an opportunity to answer the question of “how to actually select a 3D printer” in the first place. Searching the web does not yield satisfactory results; there is hardly any free information available and most content only ranks a printer based on a number of criteria, but never clarifies what that criteria means in relation to how the printer works. E.g.; nozzle size.

This makes it difficult for the amateurs to break into 3D printing, devalues products aimed specifically at novices, and alienates potential customers who would otherwise purchase your model if only they could appreciate what hell it does.

The first important question to ask yourself when hunting for a 3D printer is: what is the primary application of the printer? Are you creating concept models, verification models, pre-production applications, or what exactly? Modern printers vary according to the materials they use, feature definition, surface finish, environmental resistance, visual appearance, accuracy and precision, useful life, and thermal properties. If your goal is to create a simple concept model without any substantial working components, well then there’s no need to invest in a printer with a high level of accuracy. Instead, narrow your search based on print speed.

3D printer application review

Concept models

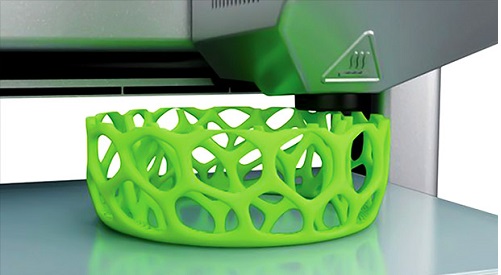

Concept models are created to give designers an idea of what the finished product will look like, without needing to function. This allows the comparison of alternative design paths at an early stage in production.

Concept models intended to display basic aesthetical design

Verification models

Verification models are intended to create a hands-on feel of the finished product and proto-type during all stages of design. Any time a new feature is added or revised, it should be tested with a verification model. For this reason, feature detail resolution, model accuracy, and material characteristics are important printer characteristics for producing an accurately functioning verification model.

Manufacturing applications

Incorporating 3D printing technologies into manufacturing grants designers an entire new level of freedom previously unseen in traditional subtractive manufacturing methods. Since subtractive techniques remove excess material, the shape of the crafted component is limited within the confines of the starting supply and there is a high amount of excess waste. Alternatively, 3D printing stacks material to create a final shape, and as a result, is unbound by not nearly as many geometric restrictions. 3D printers specializing in manufacturing operations must exhibit a high amount of accuracy, precision, and use multiple types of materials.

3D printer attributes

Print Speed

The meaning of print speed varies by vendor and technology, however, the primary definition refers to the time required for printing a finite distance in the Z-direction, or z-axis, during a single print job, e.g.; the number of inches per hour in the Z-direction. Z-direction printing methods are preferred for 3D printers that have stable vertical build speeds independent from the geometry of the parts being printed.

The second meaning of “print speed,” refers to the time required to print a complete part or part volume. If too many parts are a queued, the print speed will suffer, and hinder the scope of concept modeling.

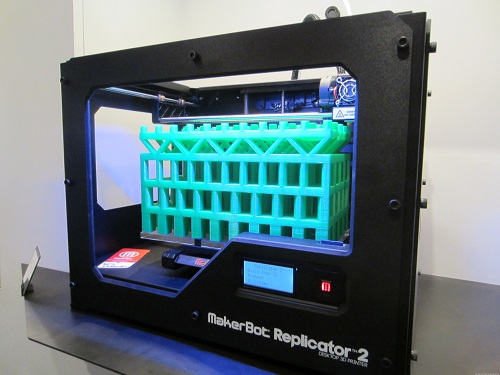

Part cost

Part cost is synonymous with production cost and is defined by the cost per volume of printing, e.g.; cost per cubic inch or centimeter. The difference in production cost between multiple printer models is one of the primary attributes to be aware of when shopping for a printer, as some models produce the same quality prints, at significantly higher prices. For example, both the Makerbot Replicator 2 and Deltaprintr produce 100 micron resolution prints, but the Makerbot Replicator 2 costs $5.36 per cubic inch of material versus Deltaprintr's $0.73 cost per cubic inch.

Cost also varies by the part complexity, so be conscious if outsourcing your part production to a third party printer as to whether the vendor is charging per individual part or a gross average across different parts.

Feature detail resolution

The printing resolution metric is often expressed in a number of ways: dots per inch (DPI), Z-layer thickness, pixel size, beam spot size, and bead diameter; however, these metrics ultimately refer to the printer’s ability to convey detail. This is apparent in the sharp edges, corner definition, sidewall quality, surface smoothness, and the minimum feature size that printer can produce.

To put things into perspective, 100 microns is considered standard for hobbyist grade printers. 100 microns is actually equivalent to 250 DPI. The lower the micron count, the higher the DPI. The Objet Connex and 3D Systems' ProJet series of printers are both reputed for printing layers as thin as 16 microns, equivalent to 1,600 DPI. A higher resolution printer is not always a justified increase in spending; this depends on the scope of the prints.

High resolution printers are beneficial in verification testing where it is critical for printed parts to accurately reflect their design. But for concept modeling purposes, the part function is second to part cost and model appearance, making this trait less important.

Accuracy and material properties

As discussed in my earlier 3D printing material guide, accuracy, strength, and flexibility, amongst other traits, differ depending on the material being used. ABS plastic is strong and flexible and requires a heating bed to solidify the end result, but does not yield a sharp printed resolution. The applied heat occasionally introduces outside variables such as material shrinkage, which can countered by applying extra material into the part. On the other hand, if material warping is triggered by the heat, the printed item is no good.

PLA plastic is more accurate than its ABS counterpart and does not require any post processing in the form of heat, yet PLA lacks flexibility, making it less ideal for building joints or interlocking mechanisms. Powder-based 3D printers are the typically the most accurate of the bunch. The binders used to unify the small particles produce the least amount of shrink distortion.

Material properties are not the only factors affecting 3D print accuracy ― part size and geometry also play a role and change with each design. Fortunately, some 3D printers provide print preparation tools for refining the accuracy for desired geometric shape.

If printing is contracted to a third party component/design printer, make certain you've defined your exact application accuracy requirements because accuracy claims are sometimes specific to only the tested parts.

Nozzle size

Most printers feature either a 0.4mm or 0.35mm nozzle. The filament extruded from the larger nozzle retains its heated temperature, and thus its stickiness, for a slightly longer period than that from the 0.35mm nozzle. This basically equates to a longer window period in which the filament can settle in the build area.

For the reason that the 0.4mm filament grips more effectively to the build plate, it also excels at binding to the previously printed layer of plastic: hotter plastic is stickier than cooler plastic. As a result, support structures are not necessarily needed for smaller prints.

Image courtesy of Zavax

The main difference between the two nozzles can be observed in the printed surface of the finished product. The smaller 0.35mm diameter nozzle packs finer layers of material, and thus a smoother, more detailed finish. Consequently, the layers produced by the smaller nozzle create a tighter surface area as well, resulting in a slightly more rigid structure.

Conclusion

3D printing is no longer the luxury that it once. Hardware innovation and the “open sourcefulness” have rendered the technology accessible to designers and artists alike, empowering anyone to bring their creative vision to life. Couple this with crowd-funding and the growing popularity of the Maker movement and entrepreneurship is more accessible than ever before. There 3D printers available for almost any budget, so shop around.

Advertisement

Learn more about Electronic Products Magazine