Graphene, for all its intents and purposes, appears to be positioned at the precipice of becoming the world’s next wonder material.

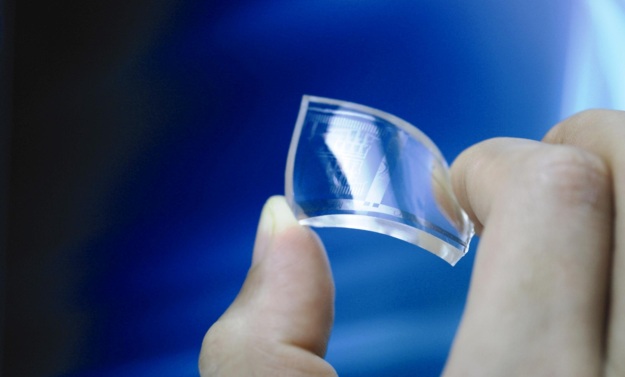

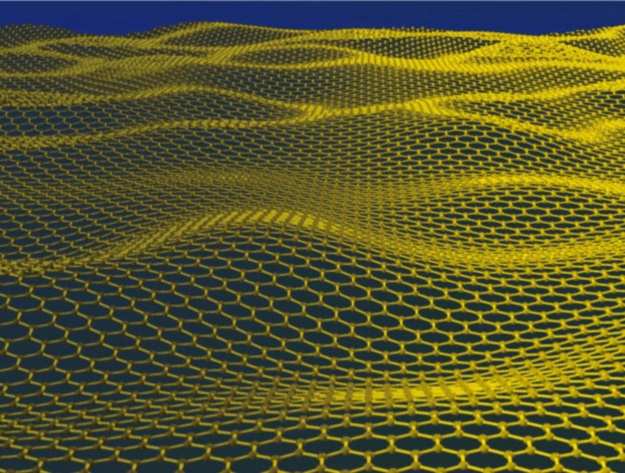

There are several reasons why. Key among them are the following: The material (a form of carbon one atom thick) is approximately 100 times stronger than steel, and it can conduct electricity at a rate significantly better than copper. For this reason, a good majority of experts believe it will eventually replace silicon in all future electronic devices.

The one thing holding it back, though, is mass production of the material. At this point in its relatively young history (it was discovered in 2004), graphene is still too expensive to produce on a large scale. That being the case, companies are hesitant about incorporating the material into any part of their devices' components for fear that it might increase the price of said gadgets and scare away customers.

So it comes as a bit of a surprise to hear that scientists have published a relatively simple process for the manufacturing of this much-desired material.

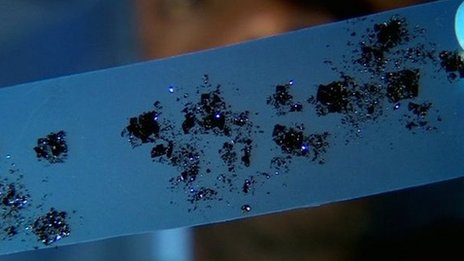

The team is made up of researchers out of Ireland and the United Kingdom. According to their report published in the journal Nature Materials (available for purchase), they poured graphite powder (the same used in pencil leads) into a blender, added a bit of water and some dishwashing liquid, and then blended the concoction at a high speed.

The shearing force generated by the rapidly rotating kitchen tool was intense enough to separate the layers of graphene that make up graphite flakes, and it was able to do this without damaging the material’s two dimensional, honeycomb structure.

Even though the process is relatively simple and straightforward, the team does not advise amateur hobbyists to try it in their homes.

The amount of dishwashing liquid necessary is dependent on a variety of factors that need to be taken into consideration prior to the mixture being put to the blade; also, the resulting black solution, which contains the desired graphene material within it, needs to be carefully separated afterwards.

Regardless, the researchers concluded that the results of their study act as an important step toward making graphene a material that can be mass-produced, and thereby included in a variety of commercial technologies.

Story via bbc.com

Advertisement

Learn more about Electronic Products Magazine