Researchers at Nanyang Technological University believe they have developed the world’s first low-cost system that can turn ordinary objects with plain surfaces — think windows, table tops, white boards, TV screens, etc. — into responsive, touch-sensitive devices.

STATINA converts normal, everyday objects into touchscreen devices.

The system, referred to as STATINA, which stands for “Speech, Touch, and Acoustic Tangible Interfaces for Next-generation Applications,” is based on principles of vibration and imaging, which, when combined, allows it to track the movements of fingers and objects. The assembly is retrofitted onto the surface of an existing object, so it’s easy to use, and its components cost only a fraction of what new touch-sensitive display screens are going for in today’s market.

NTU assistant professor Andy Khong led the research on STATINA. He says that the system, which has been awarded the prestigious Engineering Achievement Award by the Institution of Engineers, Singapore, has already proven to work on several different types of surfaces.

“Our innovative system is able to transform surfaces such as wooden tables, aluminum, steel, glass, and even plastics into low-cost touch screens,” says Prof Khong. “It means in future, you could play computer games or draw sketches on walls or windows since almost all surfaces can be made touch-sensitive with our system.”

Understanding how STATINA works is not terribly complicated. The system uses a few low-cost vibration sensors and a specially developed algorithm to pinpoint the location of a light tap on any surface. It is also equipped with low-cost web cameras to track the movements of multiple fingers or objects on a surface. The combination of these components ensures not only a speedy response, but greater accuracy too.

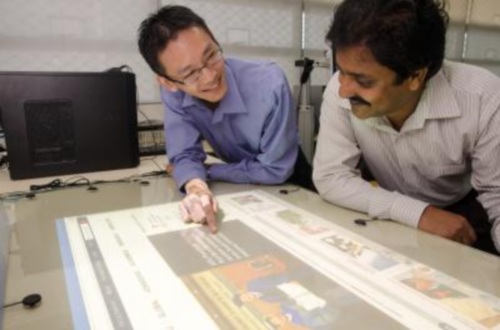

Andy Khong (left) and Research Fellow Dr. V. G. Reju using STATINA.

The technology certainly sounds exciting — there are still a few steps that need to be completed before we can all go to Best Buy to get a STATINA kit and convert our kitchen table into a gigantic iPad. Khong and his team are now working on ways to make the system more compact and also expand its capabilities to include tracking of fingers and stylus movements using optical cameras.

Also, they’ve only tested their system on surfaces like wooden tables, aluminum, steel, glass, and plastic; the group would like to explore additional surface types to see how the system responds.

Story via: ntu.edu.sg

Advertisement

Learn more about Electronic Products Magazine