By Gina Roos, editor-in-chief

Bourns, Inc. has developed the industry’s first surge-protection device to integrate a gas discharge tube (GDT) with a metal oxide varistor (MOV) in a compact package. Designed to deliver enhanced overvoltage protection, the new hybrid GMOV line of overvoltage protection components integrates Bourns’s GDT with FLAT technology with an MOV, delivering a compact and drop-in replacement for standard 14-mm and 20-mm MOVs.

The hybrid protection component design was developed to offer improved protection and to overcome some inherent challenges with discrete MOVs, including degradation and catastrophic failures when the MOVs are subjected to transient surges or a temporary overvoltage exceeding their maximum rated values. Target applications include surge-protection devices, surge strips, power supplies, and appliances.

Advantages of the GMOV line:

- Integrated and compact design

- GDT isolates MOV from line voltage; extends MOV life

- Drop-in compatible to standard 14-mm and 20-mm MOVs

- RoHS-compliant

- Meets IEEE 62.41 ring wave test

- Meets UL 1449, Issue 4, Type 5 components

“The need for circuit protection evolution is constant,” Kurt Wattelet, product line manager at Bourns Inc., told Electronic Products. “Electronics equipment continually needs to meet higher density and performance in smaller packages. More reliability, compact solutions, and energy efficiency are also key aspects for equipment.”

“In general, equipment powered by AC and rectified by DC are susceptible to transients such as lightning, switching transients, and temporary overvoltages,” said Wattelet. “As power systems are exposed to poor regulations and more transient events, discrete MOVs become more susceptible to premature failure, which can negatively impact equipment reliability.”

“MOVs have been around for about 40 years and widely used and, like all technologies, it has its limitations,” said Wattelet.

An MOV is placed across the load to provide overvoltage protection. Degradation of the MOV can happen during one of three types of transients, said Wattelet. These include lightning, which will have a high-voltage/high-current impact (when transient surge currents exceed its maximum value), a temporary overvoltage advent that is particularly harmful to the MOV and switching transients, he added.

“As damage degrades the zinc oxide structure of the MOV, the varistor voltage will decrease and you’ll get more leakage, which will cause localized heating and watt-loss heating and damage and, as it can no longer dissipate the heat, it will enter a thermal runaway condition and end its operational life,” explained Wattelet.

Over the past few years, Bourns has seen a lot of equipment manufacturers pairing a discrete GDT with a discrete MOV for a protection solution to mitigate some of the MOV’s limitations. And now, with the FLAT GDT technology, Bourns could integrate a GDT with an MOV in a small package, leveraging the advantages of both technologies in a single solution.

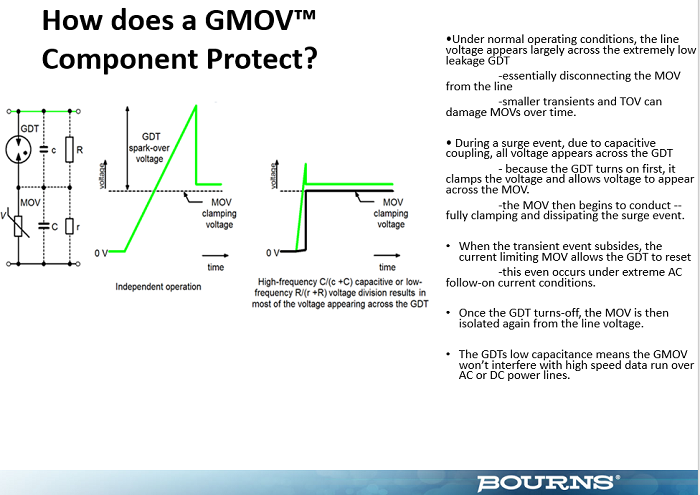

“A gas discharge tube itself can’t be used on an AC line because it will short out,” said Wattelet. “But a good way to leverage this FLAT GDT technology is to integrate it with an MOV. With the GDT in series, you’re essentially isolating the MOV from the line voltage, and that is advantageous because it will extend the life of the MOV.”

The GDT isolates the MOV from the line voltage so it remains “on call but not on duty,” thereby shielding it from transients and temporary overvoltage spikes that typically damage the MOV over time. In thermal runaway conditions, MOVs can flame out and increase the risk of fire, which often requires additional protection devices in the equipment such as fusing or thermal cutoff devices for safety. With the GMOV devices, it eliminates the need for additional protection of the MOVs.

“Another key attribute of the pairing is that MOVs are very high in capacitance, so by putting the two in series, you end up with an overall capacitance of less than 4 pF, which really makes this device useful in powerline communications applications, for example,” said Wattelet.

In addition, the GMOV device offers ultra-low leakage (

A lot of equipment manufacturers, including smoke alarms and appliances, have to be compliant to the IEEE 62.41 ring wave test, said Wattelet. The GMOV datasheet provides the spec for the 200-A ring wave test.

The GMOVs are matched up with standard MOVs, said Wattelet. It’s a kind of pre-built solution, which is already UL-approved, and it becomes an easy drop-in for a designer. “You only need to re-spin the board if your design is using two discrete devices — an MOV and a GDT.”

Key performance features include:

- Zero standby energy consumption

- No degradation from watt-loss heating

- Low capacitance

The GMOV components are offered in 14-mm and 20-mm versions, with maximum continuous operating voltage ratings from 45 Vrms to 320 Vrms. The 14-mm version has a maximum surge current rating of 6 kA, while the 20-mm version has a 10-kA maximum surge current rating. For more information, Bourns offers a whitepaper on the benefits of the GMOV.

Under development is a higher-voltage GDT that will allow Bourns to expand the GMOV range up to 550 Vrms. The company also is planning to introduce higher-current and higher-temperature GMOVs. Bourns expects to offer a GMOV line rated at 125°C by mid-summer.

Advertisement

Learn more about Electronic Products Magazine