Researchers from the Georgia Institute of Technology won a Defense Advanced Research Projects Agency (DARPA) contract to develop three-dimensional chip cooling technology able to handle heat loads as much as ten times greater than systems commonly used today. In addition to higher overall chip heat dissipation demands, the new approach will also have to handle on-chip hot spots that dissipate considerably more power per unit area than the remainder of the device. Such cooling demands may be needed for future generations of high-performance integrated circuits embedded in a wide range of military equipment.

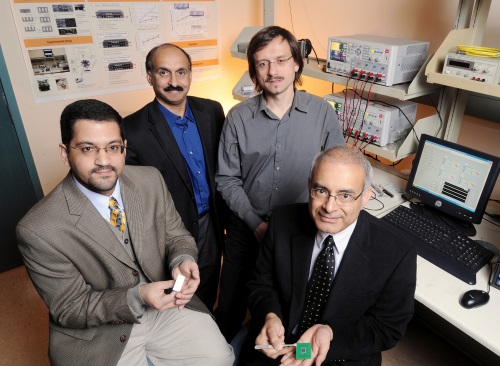

Georgia Tech researchers Muhannad Bakir, Andrei Fedorov, Yogendra Joshi, and Suresh Sitaraman are developing three-dimensional chip-cooling technology that will be able to handle heat loads as much as 10 times greater than systems commonly used today. (Credit Gary Meek.)

There’s no doubt that the challenge of dissipating heat will only get worse as computers get faster and have more capabilities. Not only that, the surface area is shrinking to mere millimeters square and that makes it even more important to control the high power on the chip.

Georgia Tech will work with DARPA’s Microsystems Technology Office, which provided the three-year $2.9 million contract, to seek techniques to dissipate heat of as much as 1 kW/cm2 in the overall IC, and 5 kW/cm2 on smaller areas. The research is part of DARPA’s Intrachip/Interchip Enhanced Cooling (ICECool) program.

While applications for the high-powered chips aren’t specified, their installation in systems intended for field use will add to the level of challenge. Cooling these high performance ICs will be even more challenging because they will operate in rugged military environments

Among the significant challenges ahead are:

• Implementing non-uniform cooling using liquid evaporation in three dimensional integrated circuits. The program calls for two dies to be cooled together, but the approaches developed for that could be used in multiple stacked dies. Being able to cool smaller areas with higher heat dissipation needs will provide an additional challenge.

• Meeting reliability standards while ensuring that the coolant and vaporization within tiny microfluidic passages does not induce liquid dry-out, passage cracking, fluid leakage or undesirable electronic performance.

• Fabricating micron-scale cooling structures smaller than the thickness of a hair in the integrated circuit stack and understanding the flow and heat transfer physics taking place at that scale.

The microscale thermal technologies that will result from this project will address the most demanding thermal needs of future 3-D nanoelectronic systems. Beyond the technology challenges, the researchers will also need to develop a detailed and fundamental understanding of how liquids boil at the micron size scale.

“The physics of how liquids boil has been well studied for large systems such as power plant boilers,” professor Yogendra Joshi, noted. “What we are talking about here is boiling that will take place in passages that are produced by microfabrication techniques that may be only 50 x 50 μm. The physics of what will be going on there is very different than what happens at the large scale, and how these liquids boil in the passages of interest will result in new scientific insights.”

Selecting an appropriate coolant able to provide the necessary phase change performance — while not damaging the silicon chips — will be part of the project. In an earlier research program supported by the Office of Naval Research, Georgia Tech developed new coolant candidates that will be considered along with traditional dielectric fluids.

The research will be done in collaboration with industry partner Rockwell-Collins, a major manufacturer of electronic systems for the military. That collaboration will help ensure that solutions developed will be compatible with defense system requirements. Beyond meeting the project requirements, the research will produce technology advances that should be broadly useful for future microsystems. For more information http://tinyurl.com/luyachd.

Advertisement

Learn more about Electronic Products Magazine