BY AJINDER SINGH, Systems Architect, and ADAM YAGER, Industrial Systems Marketing engineer

Texas Instruments

www.ti.com

There is an increasing value to sense the physical parameters around us for safety, comfort, fun and – believe it or not – to lower insurance premiums. The advancements in low-power RF and analog technology is enabling wireless sensor networks (WSN) to have more functionality and application possibilities than ever imagined. Wireless sensor networks are a network of sensor nodes that monitor environmental data such as temperature, humidity, gas, light, and occupancy and then communicate the data wirelessly to a central gateway.

When we consider WSN applications, the capability to have advanced interactivity and control is not just limited to traditional smart home applications. It also applies to the traditional industrial, health and fitness, energy exploration and beyond. With the capabilities of self-organization, self-healing pervasiveness, WSN’s are enabling even newer applications such as structural monitoring of bridges and buildings, proximity marketing in shopping malls, preventive maintenance in machines, and medical telehealth among a variety of other applications.

Sensor nodes are said to have a projected growth of 100 billion deployed by 2020 [1]. Powering these nodes becomes a true challenge in order to realize this growth. Traditional battery-powered sensor nodes have a finite energy storage that requires maintenance and logistic overhead. Sensor nodes can be potentially placed in inaccessible locations that can open up even more novel usage. Based on some research, the cost of replacing batteries in WSNs could approach greater than a billion dollars. The big question would be if there is an alternative to save this overhead and still realize the benefits of WSN –that alternative is energy harvesting. Energy harvesting can help the businesses and building owners or end users of WSN to avoid the time and cost commitments in the maintenance required to replace all these batteries.

Energy harvesting sources in building automation

From vibration sources in HVAC vents, floors, windows and various appliances to thermal differentials in HVAC units, boilers, and hot water pipes to indoor and outdoor light sources, the energy is there. However, harvesting it sufficiently and reliably is definitely a challenge. With vibration the challenge is getting the transducer designed to match exactly the vibration source. With light the challenge is when there is no light. With thermo electric generators, it is the cost of transducers and the constraints of temperature differential that restricts them. Thus, there may not be a “one size fit all” model when it comes to which energy source to harvest. Rather, a careful analysis on the application usage, constraints and design cost need to be taken into account for such system design.

Energy harvesting reference design

Proximity marketing is a relatively newer application in building automation that leverages the smartphone used by consumers. A fixed Bluetooth low energy beacon can determine proximity to a location of interest or even indoor navigation. Since the application is indoors like a commercial office space, shopping mall, or a healthcare facility, indoor light energy is readily available – which can be harvested. A typical illumination in an office building or retail store environment is usually around 500 lux or higher. This can be enough to power a wireless sensor node with low-power radio frequency (RF) capabilities.

However, there are key system design challenges that need to be understood and addressed for a reliable, autonomous WSN design that leverages indoor light energy.

Accurate power requirements

For a Bluetooth low energy beacon application, let’s look at the following assumptions:

1. A Bluetooth low energy beacon transmission once per second

2. One heartbeat LED that blinks once every 2 seconds for 100 ms (enough for visual confirmation that the system is operational)

3. System sleeps for the rest of the duration when it is neither transmitting a beacon nor blinking an LED

For the LED blinking power budget, it is important to know the forward voltage drop of the LED as well as the limiting resistor value that is connected in series. Let’s say the LED chosen has a forward voltage drop of 2.1 V and a limiting resistor value of 2.2 kΩ. The current drawn by the LED when it is ‘on’ will be (see Eq. 1 ):

~1 V / 2,200 Ω = 454 µA (Eq. 1)

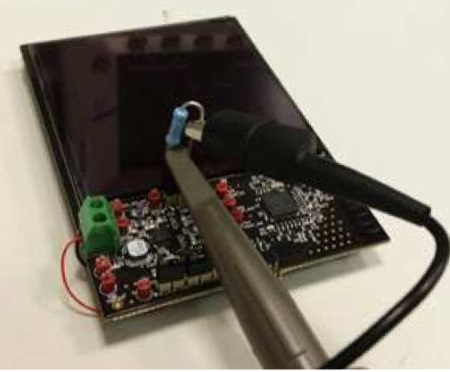

To calculate the energy budget when the Bluetooth low energy packet is being transmitted, we used the setup in Fig. 1 . Here a 10 Ω resistor was connected in series with an input power connection. This is done to ensure that dynamic power consumption can be calculated as a Bluetooth low energy packet is transmitted. A voltage probe can then be attached differentially as shown in Figure 1. The oscilloscope can then capture the voltage versus time waveform which can be converted to current versus time by factoring in the 10-Ω series resistor.

Fig. 1: Setup for Bluetooth low energy packet power measurement

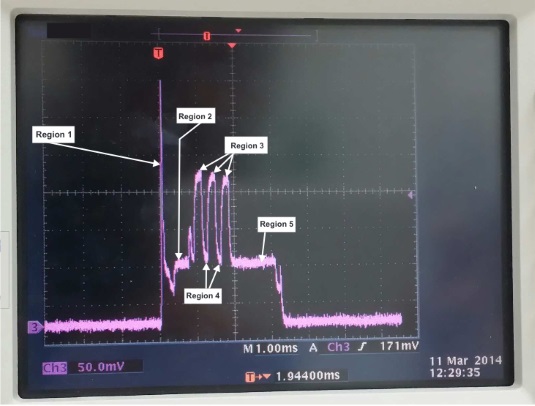

As shown in Fig. 2 , the current drawn by the Bluetooth low energy wireless device from TI when transmitting a beacon is captured. In summary, the total energy budget needed by the application is shown in Table 1 .

Fig. 2: Power drawn during beacon transmission

Table 1: Bluetooth low energy beacon power budget

Power budget calculations

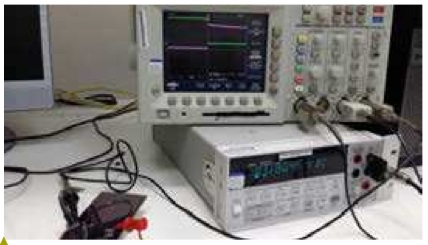

As shown in Table 1, the energy required by the Bluetooth low energy device to transmit a beacon once a second and blink an LED for 100 ms every 2 seconds, is ~179 µW/s. To confirm if the solar cell selected can support the required energy as well as confirm the minimum lighting (lux) required supporting the energy budget, setup as shown in Fig. 3 was used. The system was kept in a typical lab environment. The light measured in the setup was ~450 lux which is similar to a typical retail environment lighting. A multimeter was connected in series such that the current going into the power management device can be measured.

Fig. 3: Measurement setup

Current measured by the multimeter in-series between the solar cell and input power connector is 350 µA.

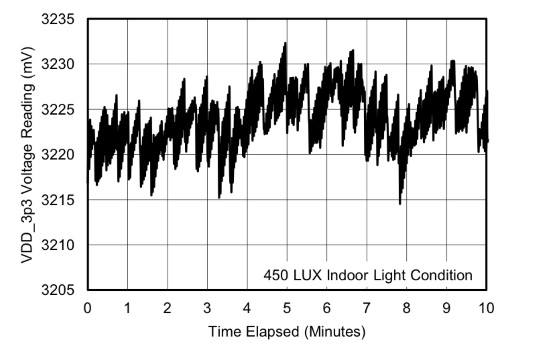

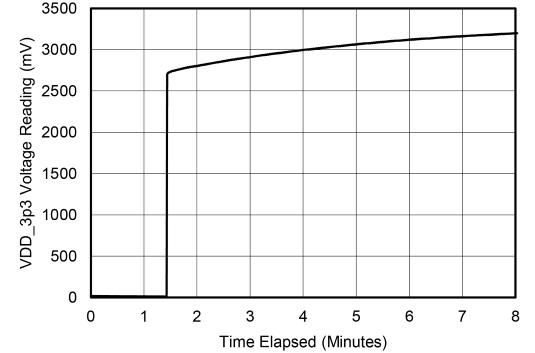

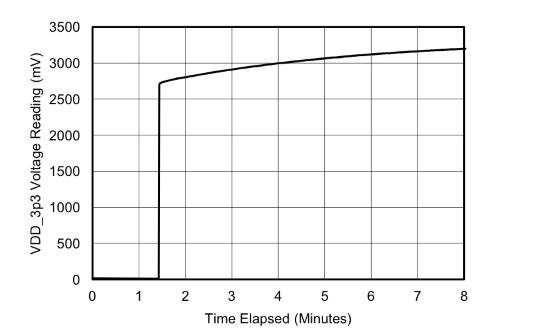

Input voltage measured: toggles between 1,095 V to 1,383 V. Power sourced by the solar cell and assuming 85% efficiency of the power management device under 450 lux is between 325 µW to 411 µW. Thus, at 450 lux, the energy provided by the solar cell is enough to charge the supercap up to VBAT_OV as shown in Fig. 4 . Note that a supercap (or supercapacitor) is an energy storage device used to store charge with advantages over a battery for these types of applications. To characterize the minimum energy required (lux) for this application to work, data can be collected with lower indoor lighting (250 lux).

Fig. 4: Load power supply rail measured during Bluetooth low energy beacon transmissions

At 250 lux, the current measured by a multimeter in series between the solar cell and the input power connector pin 2 is 195 µA.

The input voltage measured is relatively stable at 1.035 V.

Power sourced by the solar cell with 85% efficiency of the power management device under 250 lux is approximately 170 µW.

Thus based on power requirements for the application ~179 µW/s, it is evident that indoor light energy of greater than 250 lux would be required for the application to work reliably.

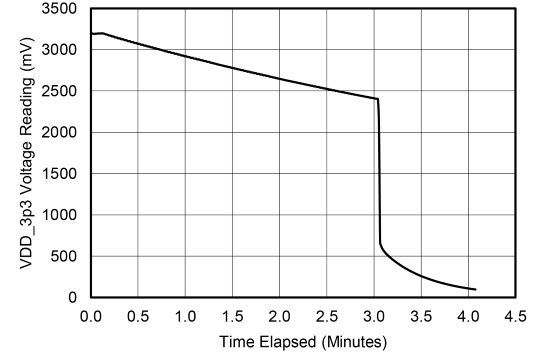

Reliable load connect – disconnect

For energy harvesting power management, it is key that the load (in this case, a Bluetooth low energy device) is connected when the power management device indicates a power good or equivalent condition has been met as well as disconnect the load when the input power level has fallen below a certain threshold. This ensures that the application can run autonomously without any intervention. Another challenge here is when a load is first connected. There is considerable strain on the power source since the power-up sequence of a Bluetooth low energy device can require significant energy, thus, creating a drop in the input voltage. Having a power management device that can have a hysteresis level to counteract that initial drop addresses this challenge. Hence, the key requirement from the energy management device is to provide programmable levels of load connect and load disconnect such that the load connect level [V] > load disconnect [V] + drop in voltage when the load is connected [V] (Figures 5 and 6 ).

Fig. 5: Load connect

Fig. 6: Load disconnect

Supercap charging

Having the power management device able to harvest energy, even at low input voltage, is crucial to ensure the application can work efficiently with a given energy harvesting source. The system design to meet the power requirements of a Bluetooth low energy device while transmitting a beacon, needs to come from an energy reservoir that can source instantaneous energy. For a majority of the time while the Bluetooth low energy device sleeps, this energy reservoir can be charged by the energy harvesting source.

A supercap is one solution that can be used as an instantaneous energy reservoir, which can be charged by a power management device. When a supercap is first connected to the power source, the supercap must be charged before it can be used. A power management device should be able to charge the supercap even at low-input voltage. As shown in Fig. 7 , until 1.8 V, the power management device operates in the cold start-mode and takes ~20 minutes to charge the supercap from no charge to 1.8 V.

Fig. 7: Supercap charging

After reaching the 1.8 V threshold, the power management device enters into normal boost charge operation. It takes approximately 2.7 minutes to charge up to the V_BAT_OK_HYST level of 2.9 V (V_BAT_OK_HYST is the voltage level at which the load gets connected), and the Bluetooth low energy beacon application starts. As shown in Fig. 7, there is enough energy sourced by the solar cell to charge the supercap up to the VBAT_OV value of ~3.2 V at 450 lux indoor light condition.

Wireless sensor networks have the ability to change the way we interact and monitor the environment around us. The indoor light energy harvesting reference design from Texas Instruments provides all the system design knowledge as well as addresses the challenges on how to reliably harvest indoor light energy and build a Bluetooth low energy beacon, thus eliminating the need of battery replacement forever.

References

1. Semiconductor Wireless Sensor Internet of Things (IoT) Market Analysis 2014 Industry Size, Shares, Growth, Trends And Forecast Research Report 2020, ResearchMoz, February 20, 2014

2. Check out the: Indoor light energy harvesting reference design for Bluetooth low energy beacon subsystems.

About the Authors

Ajinder Pal Singh is a Systems Architect at Texas Instruments, where he is responsible for developing reference design solutions for the industrial segment. Ajinder brings to this role his extensive experience in high-speed digital, low-noise analog and RF system-level design expertise. Ajinder earned his Master of Science in Electrical Engineering (MSEE) from Texas Tech University in Lubbock, Texas. Ajinder is a member of the Institute of Electrical and Electronics Engineers (IEEE)

Adam Yager is an Industrial Systems Marketing engineer at Texas Instruments where he is responsible for building automation. He received his BSEE from the University of Cincinnati, Ohio.

For questions about this article, contact: ti_adamyager@list.ti.com

Advertisement

Learn more about Texas Instruments