By Carolyn Mathas, contributing writer

For the past several years, the focus of the industrial internet of things (IIoT) and Industry 4.0 has rested squarely on subsystems, components such as sensors and switches, big data, and interconnectivity. As Industry 4.0 development continues, however, energy efficiency becomes imperative for real Industry 4.0 advances to take hold.

Industrial facilities are major energy consumers, and the availability of reliable power is critical to advanced manufacturing processes. The industrial sector can have a significant impact on global sustainability. In 2016, according to the International Energy Agency, the sector accounted for 41.6% of global electricity consumption.

Power and power management are necessary to enhance maintenance and minimize disruptions with regard to industrial robots in a market where every second counts and downtime must be avoided. Even more important, however, efficiency improvements hold the potential for substantial resource savings.

Multiple methods are available to attain energy efficiency, including but not limited to the following:

- Schedule production processes to track with peaks in energy generation from renewable sources.

- Increase efficiency of industrial robots by optimizing the speed at which they operate rather than just making them work faster via programming, thereby increasing savings by up to 30%.

- Use 3D printing to reduce material waste.

- Reduce the energy typically spent on maintenance by using a preventative strategy.

- When possible, retrofit smart meters and controllers for remote equipment.

- Implement a “lights out” environment where all humans are replaced. This delivers energy efficiency not only from the factory floor, but also in the actual energy systems within the facility.

- Use low-power components.

It is the combination of all such energy-efficiency efforts that will produce results, rather than just choosing one method and expecting it to be sufficient.

Energy-saving components

Many new products are coming to market that offer substantial energy savings. The following are examples.

Infineon Technologies AG addresses the fast-growing demand for energy-efficient silicon carbide (SiC) solutions in power conversion schemes, such as battery charging infrastructure, uninterruptible power supplies, motor drives, and energy storage. For example, the company is using the ANPC topology for its hybrid SiC and IGBT power module EasyPACK 2B in the 1200-V family.

The module features increased power density and a switching frequency of up to 48 kHz, supporting system efficiency of more than 99%. The hybrid Easy 2B power module weighs significantly less than a corresponding inverter with purely silicon components. Silicon carbide losses are smaller than silicon, so that there is less heat to dissipate and the heat sink can also shrink.

The hybrid EasyPACK 2B module features increased power density and a switching frequency of up to 48 kHz. (Image: Infineon Technologies AG)

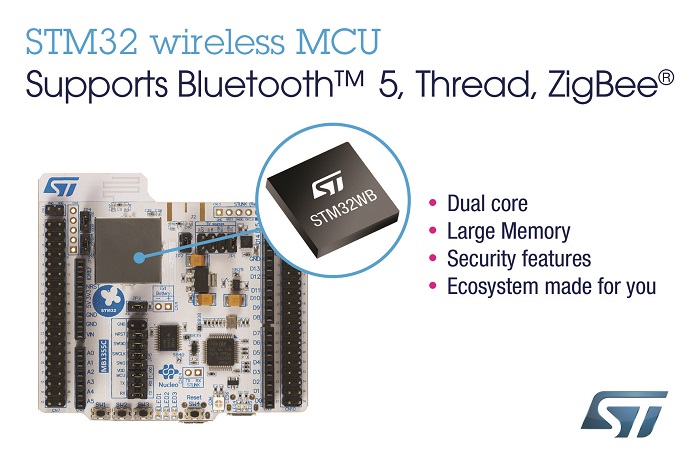

STMicroelectronics continues to address energy efficiency with new products such as its STM32WBx5 dual-core wireless microcontrollers (MCUs) and STM32G4 MCUs.

Delivering ultra-low-power performance, the STM32WBx5 wireless MCUs come with Bluetooth 5, OpenThread, and ZigBee 3.0 connectivity. Although the product is power-conscious, it is capable of concurrent wireless protocol and real-time application execution, suitable for remote sensors, wearable trackers, building automation controllers, computer peripherals, drones, and IoT devices. Features include multiple power-saving modes, such as 13-nA shutdown mode, adaptive voltage scaling, and an adaptive real-time ART accelerator that maximizes energy efficiency and ensures long-lasting performance. An integrated radio transmitter is optimized for high RF performance and low power consumption to maximize battery runtime.

STMicro’s STM32WBx5 MCUs deliver ultra-low-power performance combined with Bluetooth 5, OpenThread, and ZigBee 3.0 connectivity. (Image: STMicroelectronics)

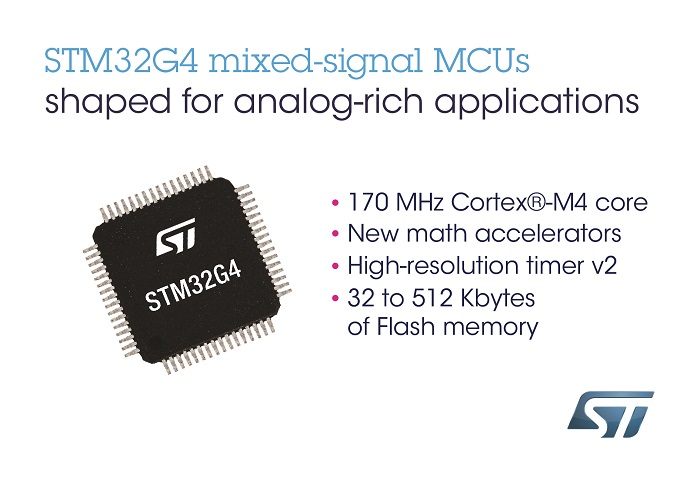

Targeted at advanced digital power applications, as well as consumer and industrial products, the new STM32G4 microcontrollers introduce two new hardware mathematical accelerators that boost the processing of applications using Coordinate Rotation Digital Computer (CORDIC). CORDIC is a computationally efficient algorithm for handling elementary mathematical functions and supports increased performance and energy efficiency.

The MCU speeds calculations for energy-saving motor controls and filtering for signal conditioning or digital power control. The accelerators compute results faster and more efficiently than the general-purpose main processor, increasing energy efficiency in a wide range of products addressing smart factory and smart energy applications.

The STM32G4’s algorithms handle elementary mathematical functions with high accuracy and filtering functions that support increased performance and energy efficiency. (Image: STMicroelectronics)

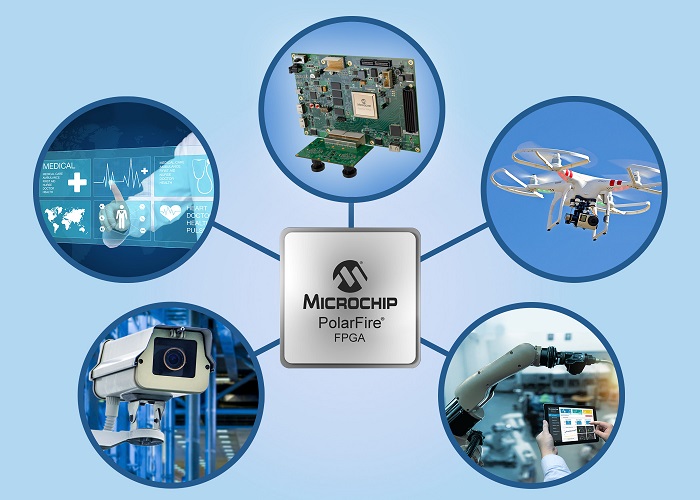

Microchip Technology Inc. recently announced a Smart Embedded Vision initiative offering FPGA-centric IP, hardware, and tools for low-power, small-form-factor machine-vision designs. The company’s subsidiary, Microsemi, simultaneously unveiled a family of low-power PolarFire FPGAs. Microsemi claims that PolarFire FPGAs provide 30% to 50% lower power than SRAM-based FPGAs and 5x to 10x lower static power. They are suited for use in compute-intensive edge devices as well as thermally and power-constrained environments.

Microchip’s Smart Embedded Vision delivers IP, hardware, and tools for low-power machine vision. (Image: Microchip Technology Inc.)

Renesas Electronics Corp. has introduced a single-chip microcontroller that features an EtherCAT slave controller for industrial Ethernet applications. The RX72M family of MCUs offers larger memory capacities for industrial equipment that mandates robust control and communication functions in applications such as energy-efficient compact industrial robots, programmable logic controllers (PLCs), remote I/O, and industrial gateways. Renesas claims that it’s the first RX microcontroller to include an EtherCAT slave controller that features 1 MB of SRAM and 4 MB of flash memory.

The RX72M devices allow for about a 50% reduction in circuit board area compared with earlier devices. (Image: Renesas Electronics Corp.)

Another important and emerging trend is artificial intelligence (AI) to deliver low-power machine intelligence. For example, Eta Compute’s latest machine learning SoC, TENSAI, performs image classification, keyword spotting, and wakeup word detection for ultra-low-power embedded solutions.

The TENSAI chip includes Eta’s delay-insensitive logic, which enables products to reliably operate at the lowest supply voltage, resulting in very low power consumption. Its image-classification application consumes a mere 0.4 mJ per picture, which is a 30x power reduction compared with competitive results. The company’s DIAL architecture combines with its algorithms to perform machine learning inferencing in hundreds of microwatts to deliver machine intelligence to the network edge.

Summary

Industrial automation is expected to grow substantially as IoT solutions replace traditional manufacturing solutions. Advanced robotics and sensors; AI and its subsets, including machine learning and deep learning; cloud computing; and big data analytics will continue to change the manufacturing industry’s landscape. Sensors powered by vibration energy or light-harvesting power supplies will become the norm.

The capital costs of the resources necessary to roll out Industry 4.0 in factories will offset potential savings in the near term. However, the systems that will replace communication technologies, actuators, sensors, processors, and more will rely on relevant data for improved efficiency while requiring a fraction of the energy to operate and generating cost savings over the long term.

Advertisement

Learn more about Electronic Products MagazineInfineon TechnologiesMicrochip TechnologyRenesas Electronics AmericaSTMicroelectronics