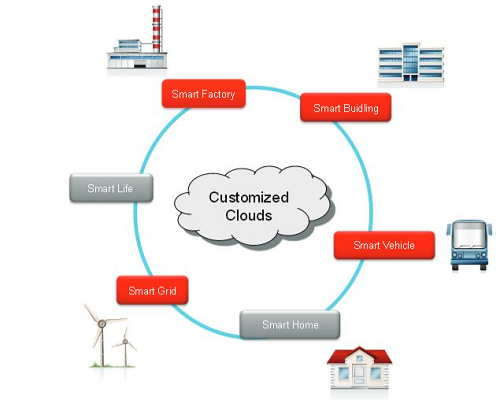

Experts argue that industry is undergoing its fourth revolution, following in footsteps of the steam power, mass production, and early automation revolutions of previous centuries. “Industry 4.0,” as it is dubbed, links control networks that were once isolated to the front office and field, introducing an entire barrage of real-time data in factories that promotes real-time decision making. Central to these dynamic factories are the networking innovations that allow a new level of faster, flexible communication, enabling plant operators to respond to changing market conditions at the drop of a hat.

With multiple solutions on the market and a high investment ceiling, companies require the security that their investment will pay off in the form of increased productivity and flexibility. This encourages solution providers, such as Texas Instruments, to strike a balance between performance and affordability. TI, in particular, is in an ideal position to usher in the revolution on account of its network communication expertise and adaptability to changing industry standards.

Smart factory advantages

Unlike traditional factories, smart factories produce an exponential amount of information, creating a situation where data that formerly affected production on an indirect level, after back-office scrutiny, can now be sent directly to the factory floor through its network connection. This creates a sudden transparency in all aspects of the factory production, essentially enabling tighter control.

For example, if a business accesses a database of customer preference, product successes and failures, repair and maintenance feedback, or changes in material availability, among other factors, it can use this information to alter its production run right-away to manufacture goods that directly reflect the demand highlighted in the sales data. A factory employing conventional Ethernet instead of Industrial Ethernet per say, cannot react at the same speed as a smart factory can. If 60 percent of your customers like black phones and 40 percent prefer white phones, why spend a week making 50/50 of each. Smarter factories can turn out a greater variety of products in greater quantities.

What's driving this manufacturing revolution?

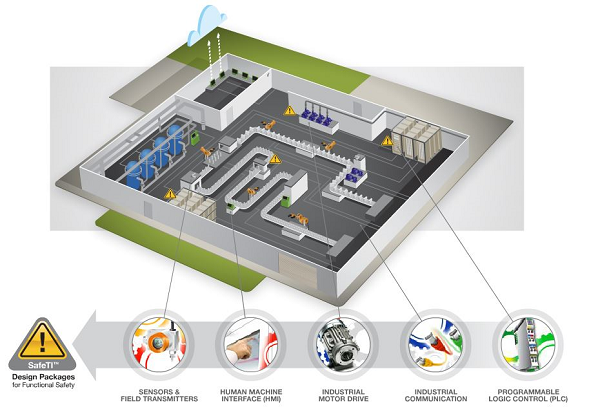

Contemporary manufacturing processes easily encapsulate more than 100,000 nodes, each requiring electronic communication between the various motors, actuators, sensors, cameras, scanners, robots, and their equipment. The automation of this many factors requires a great deal of coordinating among the vast amount of points transmitting data; precision and robustness are therefore key, and advanced communication technologies such as Industrial Ethernet make it possible to maximize productivity and minimize costs.

Sophisticated communications on the factory floor can also reduce the downtime of nonfunctional machines by reporting problems as soon as they occur, ensuring that machines remain operative for the longest possible duration. This ultimate increase in efficiency directly results in less power consumed in producing each item; the less power consumed, the higher the cost effectiveness of the investment ― smart factories are green factories in a broad sense. Yet competition is an ultimate driving force in industry, and if the rest of the world is innovating, becoming more interconnected, then factories must do same.

TI's contribution

Last fall — at SPS IPC Drives in Nuremberg, Germany — TI unveiled its premier Industry 4.0 solution based on wireless connected sensors and analog embedded processing technologies. The solution takes advantage of TI's Bluetooth low energy SensorTag kit, based on SimpleLink™ CC2541 wireless MCU, adds a range of additional wireless connected sensors.

A SimpleLink C3000 Wi-Fi module included in the solution enables remote access for sensor maintenance, configuration through a remote web interface, and data storage to the cloud. Furthermore, one of the wireless sensors uses NFC technology leveraging TI's latest NFC contactless transceiver and dynamic transponder interface product solutions.

Lastly, the indispensable AM3359 ARM Cortex-A8 microprocessor provides TI solutions with production-ready industrial Ethernet and Fieldbus communication protocols with master and slave functionality including: EtherCAT®, Ethernet/IP, PROFIBUS®, PROFINET®, POWERLINK, and SERCOS III.

Orderable Mouser parts:

• AM3359 ARM Cortex-A8

o DDR3, NOR Flash, SPI Flash

o OLED Display

• TPS65910 Power management

o 24V Power supply with regional adapters and cables

o USB Cable for debug

o RoHS Compliant

Advertisement

Learn more about Texas Instruments