James Watt's improvements to the steam engine in the late 18th century increased the productivity of the textile industry and kick-started the First Industrial Revolution .

The Second Industrial Revolution dates from Henry Ford's introduction of the assembly line in 1913, where assembly lines increased productivity and cut costs.

The Third Industrial Revolution resulted from the introduction of the computer in the 1970s, giving rise to another major inflection point in productivity.

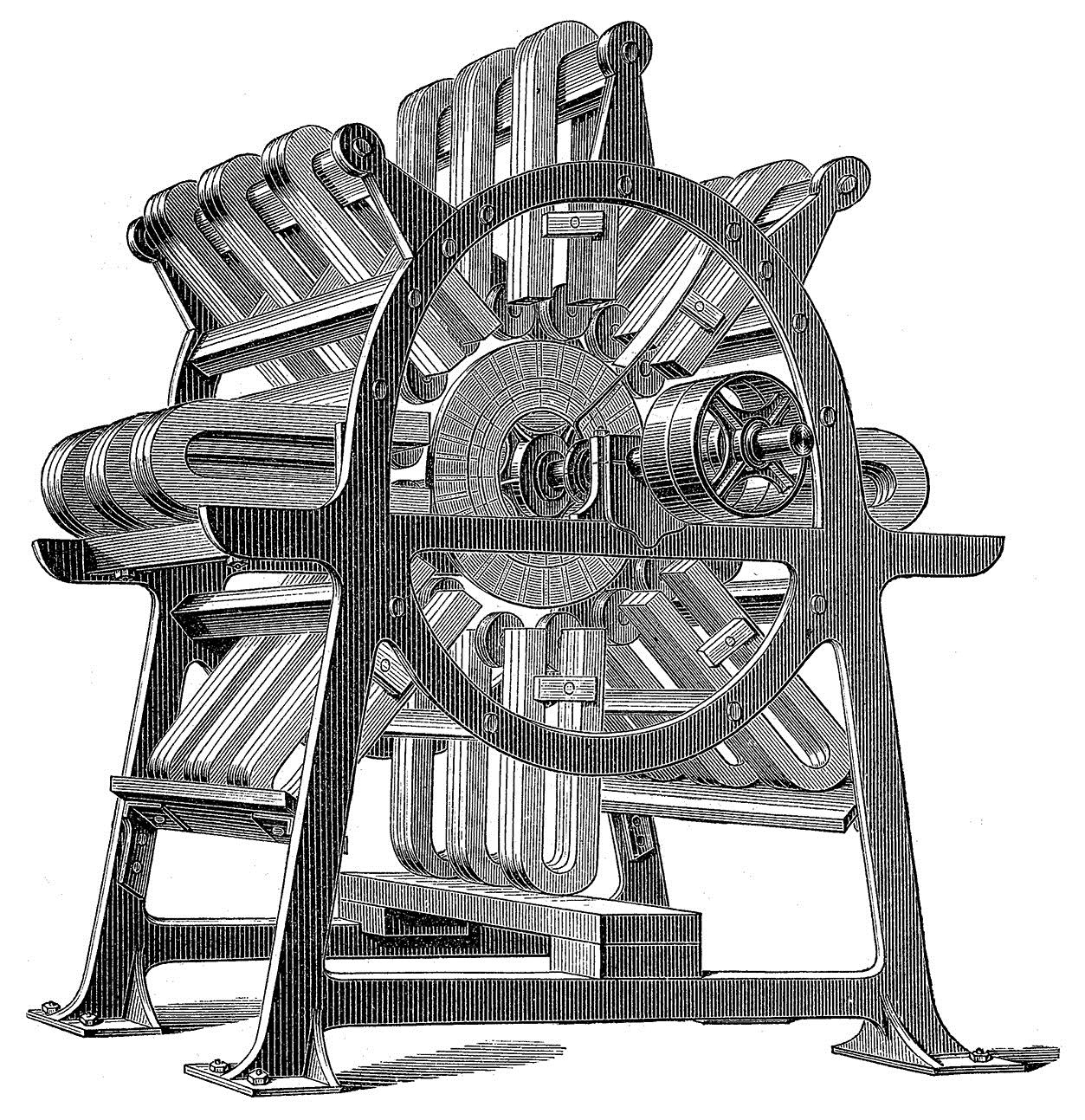

Fig. 1: Electric dynamo. Meyers, 1877.

And now we have a new Industrial Revolution: Industry 4.0, which is a vision for “cyber-physical production systems” in which sensor-laden “smart products” tell machines how they, the products, should be processed. Processes govern themselves in a decentralized, modular system. Smart embedded devices work together wirelessly to revolutionize production. Centralized factory control systems give way to decentralized intelligence as machine-to-machine (M2M) communication hits industry. This is the Fourth Industrial Revolution .

The concept of cyber-physical systems was first defined by National Instruments in 2006 and based on a virtual manufacturing process in software. In January 2012, the German Federal Ministry of Education and Research set up a working group to draft recommendations for implementing “Industry 4.0,” a term coined by the group. Industry 4.0 is now part of the official German strategy, and Germany is actively pursuing private-sector partners.

Currently more vision than reality, Industry 4.0 has potentially far-reaching consequences. However, some things are clear:

- Sensors will be involved at every stage of manufacturing, providing raw data as well as feedback to control systems.

- Industrial control systems will become more complex and widely distributed, enabling flexible, fine-grained process control.

- RF technologies will tie together the distributed control modules in wireless mesh networks, enabling systems to be reconfigured on the fly.

- Programmable logic will become increasingly important because it will be impossible to anticipate all the environmental changes to which control systems will need to dynamically respond.

- Smart, connected, embedded devices will be everywhere.

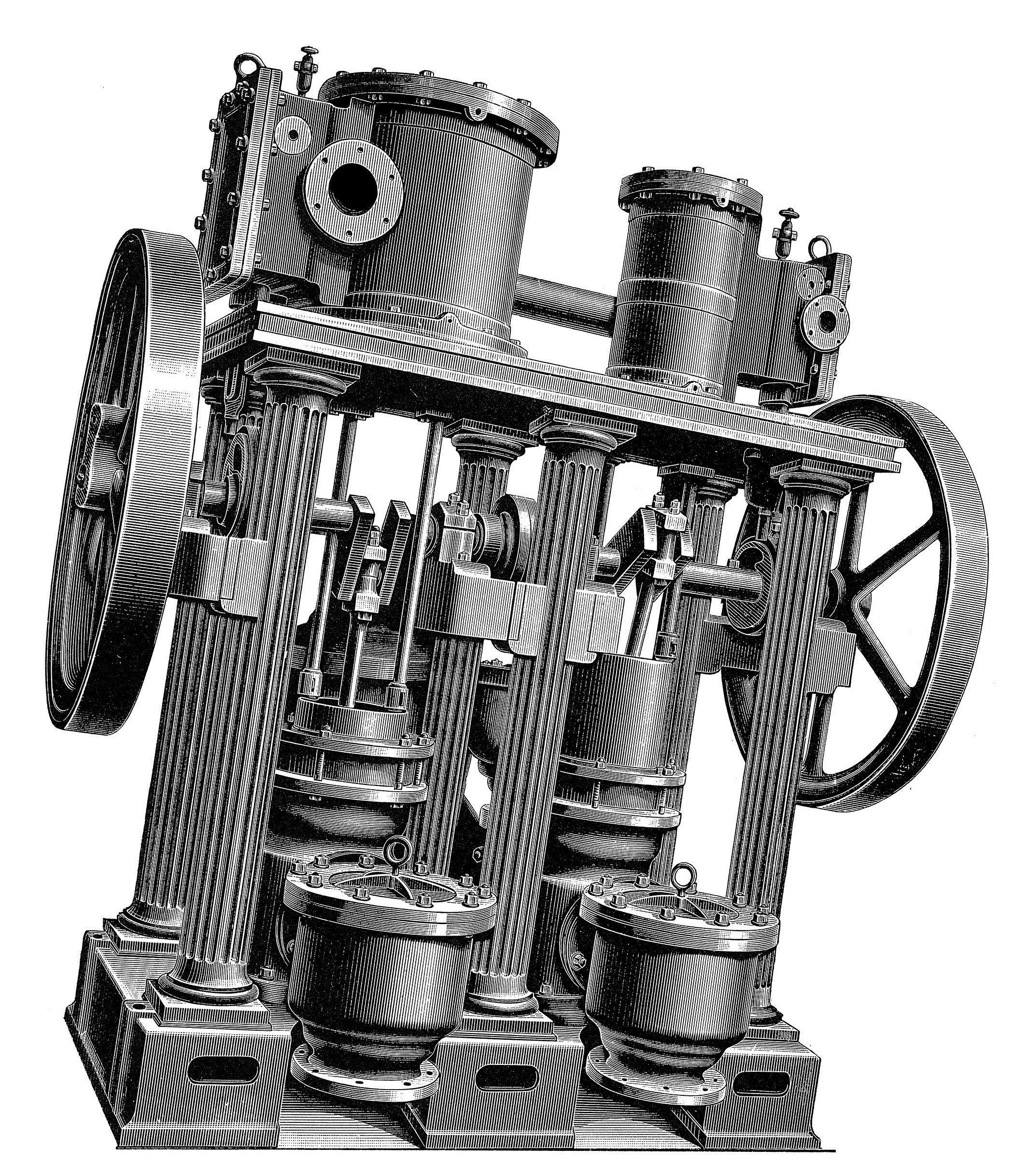

Fig. 2: Greek columns on an unidentified machine.

Most of what is needed to implement Industry 4.0 exists today. Radios, sensors, and modules can track circuit board assets. But instead of passively tracking an RFID-tagged PCB down an assembly line, the Industry 4.0 pick-and-place module alerts inventory before memory chips run out. If the chips cannot be restocked in time, then all other relevant machines in the factory reprogram themselves to begin producing the next product for parts that are in stock, drawing from remote inventory as needed. Meanwhile, second-source suppliers are alerted and assets are automatically reconfigured accordingly. The result is an enormous savings in time and cost.

Revolution or evolution?

Industry 4.0 may not be recognized as revolutionary in retrospect. But this natural consequence of M2M communication further automates factories, and should result in greater efficiency and lower-cost products.

By John Donovan for Mouser Electronics.

Advertisement

Learn more about Mouser Electronics