Taking another step toward reducing its carbon footprint and promoting sustainability, Infineon Technologies AG has announced that it is using Soluboard, a recyclable and biodegradable printed circuit board (PCB) substrate based on natural fibers and a halogen-free polymer, for its demo and evaluation boards. These recyclable PCBs supports the company’s commitment to the responsible collection and recycling of electronics products under the EU’s Waste of Electrical and Electronic Equipment (WEEE) directive.

Infineon also is looking at the potential of the material for all boards for a more sustainable electronics industry in an effort to meet the European Commission’s “Green Deal” agenda, which aims to achieve climate neutrality by 2050.

Soluboard, a plant-based PCB material made from natural fibers and developed by UK start-up Jiva Materials, is reported to have a much lower carbon footprint than the traditional glass-based fibers. “The organic structure is enclosed in a non-toxic polymer that dissolves when immersed in hot water, leaving only compostable organic material,” said Infineon.

The non-toxic polymer in the Soluboard PCB dissolves when immersed in hot water, leaving only compostable organic material. (Source: Infineon Technologies AG)

The two key benefits of the biodegradable material: it eliminates PCB waste and allows the electronic components soldered on the board to be recovered and recycled.

“Adopting a water-based recycling process could lead to higher yields in the recovery of valuable metals,” said Jonathan Swanston, CEO and co-founder of Jiva Materials, in a statement. “In addition, replacing FR-4 PCB materials with Soluboard would result in a 60 percent reduction in carbon emissions – more specifically, 10.5 kg of carbon and 620 g of plastic can be saved per square meter of PCB.”

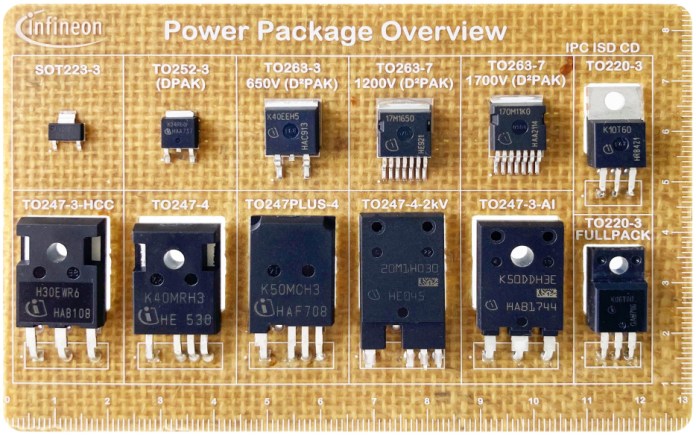

Three Infineon demo boards using the Soluboard technology are available now. Currently, there are more than 500 units in use to showcase Infineon’s power discretes portfolio, including one board that features components for refrigerator applications. The company plans to expand the offering over the next few years.

The Soluboard technology allows the electronic components on the board to be recovered and recycled. (Source: Infineon Technologies AG)

Infineon plans to provide guidance on the reuse and recycling of power semiconductors removed from the Soluboards, based on ongoing stress tests, “which could significantly extend the lifetime of the electronic components,” and “contribute to the development of sustainable designs.” The research also will provide information about reliability challenges with the new material.

Advertisement

Learn more about Infineon Technologies