Infineon Technologies AG has extended its CoolSiC portfolio with the introduction of M1H technology 1,200-V SiC MOSFETs with enhanced features. These devices will be available in Easy modules and discrete packages using the .XT interconnect technology. Applications include solar energy systems, fast electric-vehicle charging, energy storage systems, and other industrial applications.

Infineon is introducing new package features for both modules and discrete components with enhanced thermal performance, and the new M1H technology derivative also offers an extended operating window for the gate operation, said Peter Friedrichs, Infineon’s vice president of SiC, during a video presentation.

Friedrichs stresses that the new M1H variant is an upgrade to the previous M1 technology with the same basic device concept, so there are no changes to the cell layout or cell dimensions. He also noted the number of products will be significantly increased for both discrete devices and modules. Reference boards also will be added to the portfolio.

One of the most important advances to the CoolSiC base technology is its significantly larger gate operation that improves the on-resistance for a given die size, said Friedrichs. With the M1H technology, Infineon can offer the full window of gate voltages even down to –10 V at the highest switching frequencies, he said.

The wider operating gate voltage range also helps with driver and layout-related voltage peaks at the gate, said Infineon.

In addition, the datasheet now provides more details about the gate-source voltage, including maximum transient voltage from –10 V to 23 V and maximum static voltage from –7 V to 20 V, as well as recommended gate voltages. “As in the past, the recommended gate voltage is what we believe is the best performance you can achieve with respect to total losses and reliability,” said Friedrichs.

CoolSiC M1H technology provides a wider selection of gate voltages. Click for a larger image. (Source: Infineon Technologies)

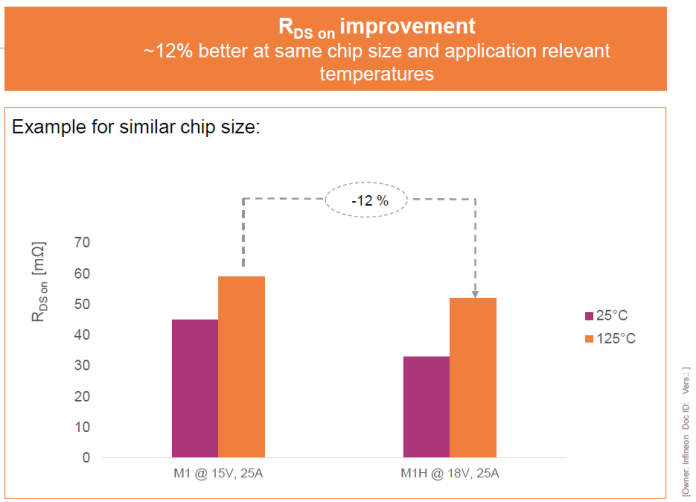

Another feature of the M1H technology is the improvement of the RDS(on) [on-resistance] given the die size, said Friedrichs. “Approximately 12% lower RDS(on) is now possible with this new technology derivative compared with the previous generation [M1] at operating temperature.”

The M1H technology offers a 12% RDS(on) improvement over the previous-generation M1 devices in the same chip size. Click for a larger image. (Source: Infineon Technologies)

Module upgrades

The M1H technology will be integrated into Infineon’s Easy module family to improve the Easy 1B and 2B modules. In addition, Infineon is rolling out the new Easy 3B module with the 1,200-V CoolSiC MOSFET, which offers a maximum temporary junction temperature of 175˚C for greater overload capability. This enables higher power density and coverage of failure events.

Infineon CoolSiC M1H SiC MOSFET in Easy 3B module. Click for a larger image. (Image: Infineon Technologies)

The Easy 3B doubles the size of the Easy 2B and is able to double the power-handling capability, said Friedrichs.

“We have now rolled out new die sizes, which gives us much more flexibility in designing particular products and also particular topologies in a wide range of power ratings: We start from 13 mΩ in the largest die and go up to 55 mΩ,” he said. “Another new added feature for power modules is a short-term overload capability where we can operate the devices up to 175˚C junction temperature. This is, of course, very important to manage certain overload or stress loads.”

Compared with its M1 predecessor, Infineon also made a change to the internal gate resistance (RG) of the M1H modules, with an increase from 4 Ω to 8 Ω, enabling the optimization of the switching behavior. Friedrichs said this enables a faster and easier design-in for customers while maintaining the same basic behavior in turn-on and turn-off for both variants.

Infineon plans to introduce a large portfolio of Easy module configurations with a variety of topologies. These include half-bridge, full-bridge, SixPACK, booster, and three-level modules.

Low-ohmic discrete packages

In addition to upgrades to the Easy module family, Infineon has added low-ohmic discrete SiC MOSFETs in TO packages using the company’s .XT technology, previously introduced in the D2PAK-7L package. The CoolSiC MOSFET 1,200-V M1H portfolio includes new ultra-low on-resistances of 7 mΩ, 14 mΩ, and 20 mΩ in the TO247-3 and TO247-4 discrete packages.

Infineon CoolSiC M1H 1200-V SiC MOSFETs in TO247 package. Click for a larger image. (Image: Infineon Technologies)

The new SiC MOSFETs are easy to design-in, especially due to the gate voltage overshoots and undershoots with the new maximum gate-source voltage down to –10 V, said Friedrichs. In addition, they come with avalanche and short-circuit capability specifications.

The new types include a device with an on-resistance of 7 mΩ, which offers the lowest on-resistance in a single product configuration in the TO package at 1,200 V, said Friedrichs. The power rating can go up to 30 kW for the 7-mΩ parts and 15 kW to 22 kW for the 14-mΩ and 20-mΩ devices.

One of the biggest gains from the low-ohmic part is that the user does not need to parallel to achieve certain power ratings in a single package, so more power and less weight can be achieved, said Friedrichs.

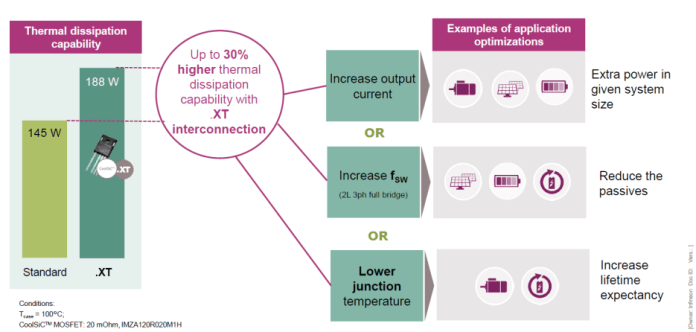

In addition, the .XT interconnection technology improves the thermal dissipation capability by up to 30% compared with a standard interconnection, said Friedrichs. This provides users with various optimizations, such as increasing the output current, increasing the switching frequency, or lowering the junction temperature in order to improve the lifetime expectancy, he added.

The .XT interconnection delivers up to 30% higher thermal dissipation capability. Click for a larger image. (Source: Infineon Technologies)

This translates into a 15% improvement in thermal conductivity or a reduction in the number of passive components due to the increase in the switching frequency. In addition, without changing the system operating conditions, the .XT technology will lower the SiC MOSFET junction temperature, which will significantly increase the system lifetime and power-cycling capabilities, said Infineon.

Benefits include >25% reduction on junction-to-case thermal resistance (Rthjc), a >45% reduction on junction-to-case thermal impedance (Zthjc), and lower thermomechanical stress, which also increases power-cycling capabilities, said Friedrichs.

The module and discrete variants are available now. These include the new Easy 3B module using the 1,200-V CoolSiC MOSFET and the low-ohmic TO247 discrete devices with the .XT interconnection.

Advertisement

Learn more about Infineon Technologies