A review of what we will call integrated passive components is in order. I think this type of component will be the norm for medium- and high-volume designs in a few years. It should be noted that I also said this a few years ago — but this time it's for sure.

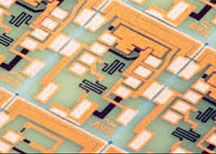

The High-Q Integrated Passive Device (IPD) process technology from ON Semiconductor offers a copper-on-high-resistivity-silicon platform ideal for the production of passive devices such as baluns, filters, couplers, and diplexers that are used in portable, wireless, and RF applications. ON Semi makes a foundry shuttle service available for engineering prototypes.

ON's innovative 8-in. wafer technology delivers higher performance than less sophisticated Cu Si processes at a far better cost than expensive, ultra-high-performance gold-on-GaAs-based passive products. IPD technology supports fabrication of inductors, precision capacitors, and precision resistors. A full-feature design kit is available to customers for layout, simulation, and verification.

Inductors come with 5- or 10-µm copper thickness, up to 40 µm wide and in 1 to 50-nH values. Capacitor values range from 1 to 100 pF and resistors are 2 µm wide and a minimum of 9 µm long. The HighQ process technology offers thick copper inductors, MIM capacitors (0.62 fF/μm2 ), and TiN resistors (9 Ω/square).

One problem with integrated passive components is that the industry has not given it a standard name.

AVX calls its interesting products Passive Micro Components. PMC thin-film technology is said to offer superior space saving, tolerance, and signal integrity for semicustom designs in the MHz to GHz spectrum.

Benefits include 0.05% tolerance or match, controlled parasitic ESR and ESL, 4-μm line width miniaturization, and laser trimming and tuning at die and wafer level. The devices can be packaged via BGA, LGA, or wire bond. They can have resistors made from TaN or SiCr with values from 0.47 Ω to 20 MΩ. Capacitors of XR7 material range from 2.2 to 400 nF and tight tolerance capacitors (±0.5%) using SiON, SiO2 , or BCB materials are available. Copper inductors 1 to 20 μm thick are available range from 0.5 to 40 nH with a 5% tolerance.

Ipdia of Caen, France has developed a unique IPD technology that efficiently integrates tens to hundreds of passive components. The devices can reduce the size of boards by a factor of 10 and are said to provide greater reliability and cost reductions can be achieved by replacing external SMD components by customized IPD dies.

The company, a spin-out of NXP, was formed in June 2009, and its manufacturing facility is certified ISO 9001/14001/18001 as well as ISO TS 16949 for the automotive market and ISO 13485 for medical devices. It offers silicon capacitor arrays from picofarads to tens of microfarads designed for hi-rel applications. They operate from as wide a range as -55° to +250°C with capacitance shift limited to ±1%. Other versions handle -55° to +200°C and -55° to +150°C. The devices offer up to 2 µF/mm3 and can integrate high-Q inductors, resistors, zener diodes, and PIN diodes.

Advertisement

Learn more about Electronic Products Magazine