By Jean-Jacques DeLisle, contributing writer

A team of researchers led by groups at MIT, the University of California at Berkeley, and Boston University have announced the development of a new microprocessor that can integrate optical communication components with electrical components all on the same chip. The new technique makes use of older chip technology and established manufacturing processes, allowing for the optical components to be deposited on the same layer of silicon as the electrical components. The addition of optical components to a microcontroller is monumental because it allows for a massive increase in communication speed while taking up nearly 20 times less space than conventional photonic components.

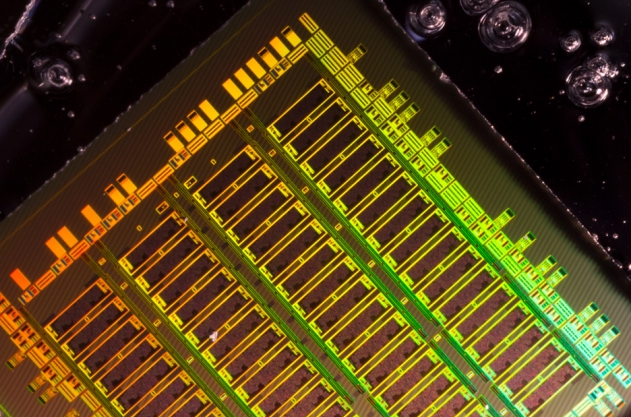

Image source: MIT.

According to Amir Atabaki, a research scientist at MIT Research Laboratory of Electronics and one of the three first authors on the new paper, the advancement will allow optics to be added to existing technologies with ease in the future. “We have different silicon electronic technologies, and if we can just add photonics to them, it’d be a great capability for future communications and computing chips,” he said. “For example, now we could imagine a microprocessor manufacturer or a GPU manufacturer like Intel or Nvidia saying, ‘This is very nice. We can now have photonic input and output for our microprocessor or GPU.’ And they don’t have to change much in their process to get the performance boost of on-chip optics.”

The drive for the industry to move away from electronic communication components and toward optical components is fueled by power consumption. Previous optical communication components were too large and inefficient, producing massive amounts of heat and taking up as much as 20 times the amount of space that is taken up by the new MIT design. The secret to the new optical components efficiency is silicon, which has been used in microchips for decades. Now, the researchers discovered new ways to arrange the crystal structure in order to allow optical and electronic components to exist within the same system.

Impressively, the researchers used a special type of silicon known as polysilicon formed into small wafers to create the microcontrollers. According to Atabaki, the team went through more than 50 silicon wafers before finding the right material. To make the advancement, they used the manufacturing facilities at SUNY Polytechnic Institute’s Colleges of Nanoscale Sciences and Engineering.

These new chips allow for faster, more efficient communication and can be expected to make a massive contribution to the advancement of modern technology. Every day brings new advancements and brings new tools to bear for engineers and developers everywhere. The Semiconductor Industry Association has estimated that, at current rates of increase, computers’ energy requirements will exceed the world’s total power output by 2040, which means that more efficient chips are essential if mankind continues to develop new technologies.

Advertisement

Learn more about Electronic Products Magazine