By Carolyn Mathas, contributing writer

5G wireless communications will require a variety of technologies that transform and meld without skipping a beat — or, in this case, a signal. These disparate technologies include antennas, printed-circuit-board (PCB) materials, and connectors, along with existing network components.

There are big changes with 5G networks that have a significant impact on connectors and cable systems — 5G is 100× faster than 4G, topping out at 10 Gbits/s (theoretical max), and they operate in both LTE frequency and millimeter-wave bands. But widespread adoption of 5G will require the ability to access it without substantial cost.

There are all sorts of challenges and barriers to 5G. As frequency increases, maintaining impedance is more difficult. The most minute anomalies, based on geometry, latency, size, or even material selection, severely impact 5G transmission. PCB effects, for example, such as surface roughness, thermal dissipation, and thermal expansion have greater impact on 5G than any past generations.

Connectors and signal integrity are at the heart of 5G. The precision necessary for connectors to transfer information as data transfer rates explode depends on several factors. Signal integrity must be maintained even though the current is high, the voltage cannot waiver, and PCB materials must evolve yet be common enough for low-cost usage.

5G networks will beam ultra-fast data to a larger user base. The short wavelengths of 5G will enable the use of small antennas, and massive multiple-input, multiple-output (MIMO) techniques will multiply wireless connection capacity. For this to take place, connector precision is critical in circuits that transmit information, especially as data transfer rates increase.

While there are several 5G connectors on the market, true 5G optimization is another story. It’s that optimization that will be key.

Lieven Decrock, TE Connectivity technologist and principal electrical engineer, believes that we’re not there yet: “Connectors for 5G are not just standard connectors that connect bits and pieces inside a box. 5G data volume generation will be that big, and connectors need to be able to transfer that vast amount of data. Connectors and connector systems, including cable assemblies for 5G antenna systems, need to combine thermal performance, signal integrity (high-speed) performance, and EMI performance, as well as have a low cost and automatic assembly.

“The thermal dissipation inside the 5G boxes — antenna systems, remote radio units (RRUs), baseband processing units, edge products — is getting to a critical level. Speeds are going up, FPGAs and ASICS are consuming more power, optical engines for optical transport generate more heat, and even more connectivity will be needed to support data transport that’s anticipated in a 5G world.”

Connectors and technologies

5G connector technology is already launching, and there are some existing products that can be used for 5G applications. Several companies have products to market, including TE Connectivity and Molex . Here’s a look at a few of their product offerings and technologies that are supporting 5G while it continues to evolve:

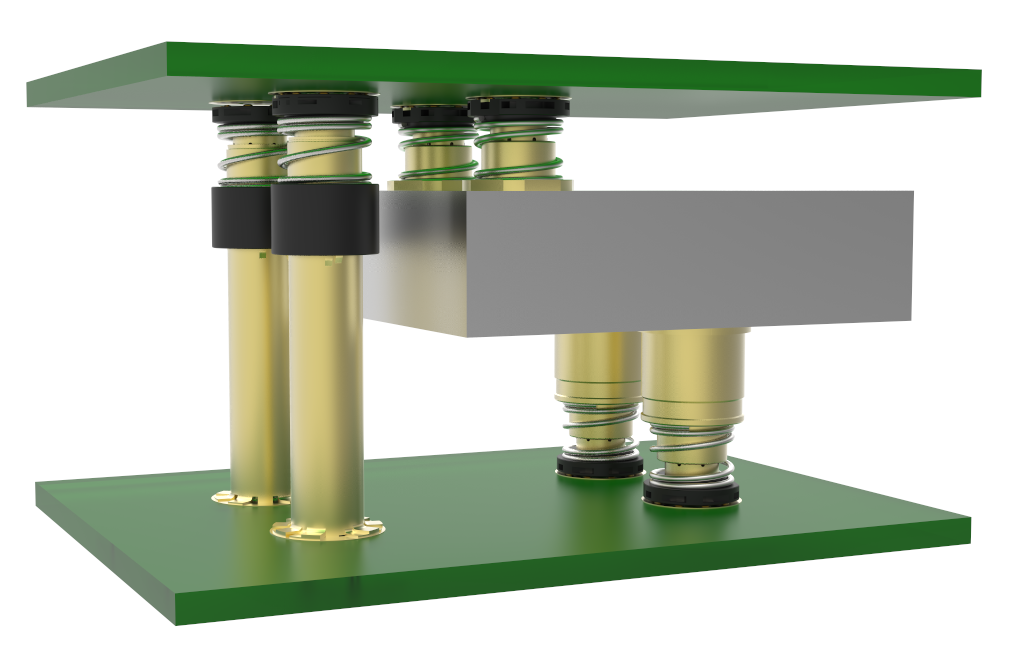

TE Connectivity’s ERFV coax connectors solve tolerance variations that exist in the front end of an antenna system. These connectors are placed between the antenna board and the filter and between the filter and the radio board. All antennas (e.g., 64 pieces) are mounted on a carrier (PCB) and have their own feeding point, which are typically coax-style connectors. Considering that these 64 coax connectors must be aligned and mated at one time, it’s a huge task. The ERFV connector is also pick-and-place–ready, requiring no manual interaction for mounting, which is an important consideration for automatic assembly lines.

TE’s ERVF RF coax connectors provide high reliability and extreme tolerances and overcome insertion and return loss. (Image: TE Connectivity)

TE Connectivity also offers the Sliver Series connectors , which are adopted as the standard connector for the SFF-TA-1002 specification, supporting high-end data-intensive applications. They provide optimal signal integrity and space savings. Featuring a highly robust metal housing on the connector cage, the design helps withstand cable pull, and an active latch provides additional connection security. By eliminating the need for re-timers and costly low-loss PCB materials, the connectors simplify design and lower overall costs yet reach speeds up to 56 Gbits/s with the use of TE high-speed cables.

Molex also offers several connector solutions that currently support 5G requirements. “Currently, there are several connectors that can support the signal integrity requirements for 5G, but it’s each customer’s unique needs, mechanical fit, and thermal requirements that are driving the customization of 5G connector solutions,” said Dan Wandolowski, Molex group product manager.

Molex offers the 2.2-5 form-factor RF connector system and cable assemblies for high-frequency and low passive intermodulation (PIM). (Image: Molex)

The Molex 2.2-5 RF connectors , innovated by adapting and miniaturizing the 4.3-10 form factor, are 53% smaller, with frequencies to 6 GHz. Targeting the needs of wireless and 5G network infrastructures, the connectors provide performance and withstand extreme elements.

Molex offers custom assemblies, integrating the connectors in a range of mating options for design flexibility, ease of installation, and optimal performance. The 2.2-5 system, with an air dielectric interface, provides superior bandwidth and low insertion loss in 5G networks and in any application with critical signal capacities and space.

“When reviewing 5G with our customers, the zSFP+ , SFP-DD , and zQSFP+ are the Molex I/O connector families that address 5G needs, which we customize to achieve specific requirements,” said Wandolowski.

- The zSFP+ interconnect system for 56-Gbits/s serial channels delivers high signal integrity and superior EMI protection.

- The SFP-DD (Double-Density) module and cage/connector system delivers a two-lane electrical interface, complementing QSFP-DD top-of-the-rack interfaces, and addresses issues caused by underpopulated lanes in file server interconnects. Thermal management for current SFP form factors is limited to connectors that generate 1.5 W. SFP-DD cages use a longer structure, providing more area to dissipate heat and offering 3.5-W thermal management for high-signal-integrity performance.

- The zQSFP+ connectors transmit up to 25-Gbits/s per-serial-lane data rates with excellent signal integrity. The zQSFP+ interconnect system with thermal protection offers three options to manage heat: a through-flow cage optimized to allow airflow through the midsection of the cage, an internal riding heat sink, and a top-riding heat sink to increase airflow and manage the additional heat generated by the 5-W plugs.

Where are we now?

While the power of 5G is often touted in terms of the less than four seconds to download a full feature film versus six minutes on 4G, consumer apps are probably not where the focus will be. Big data, massive IoT, industrial automation, connected cars, and robotics are all likely beneficiaries. Not one specific killer app, however, has been identified to dramatically drive implementation.

Even though 5G products are coming to market, 4G, 4G LTE, and 3G will continue to co-exist. Although there are still infrastructure issues to solve, wireless network providers are rolling out 5G, but widespread coverage will likely take a few more years. In addition, energy grids will need bolstering to accommodate small-cell and massive MIMO base stations, and safety, security, and standard disparities will need to be solved.

For interconnects, 5G designers can expect continued advances in connector technologies and greater optimization of existing technologies to further 5G implementation in the near term.

Advertisement

Learn more about Molex