JACOB SEALANDER, Chief Architect,

Integrated Systems, Curtiss-Wright Defense Solutions,

The successful design of Military systems demands a full understanding of the complex performance requirements, testing, and environmental conditions to which the intended product must achieve. This reference guide focuses on international military standard Input Power requirements. It is intended to serve as a reference for comparing the requirements of one standard with another. It’s also intended to help the reader understand the significant amount of work needed to become experts in the various standards and their very different ways of discussing similar performance specifications.

Input power and the compliance matrix

System design engineers are frequently faced with the time-consuming task of filling out a Compliance Matrix to ensure that the Input Power of their system will conform to a specific military system standard. The Compliance Matrix will often consist of many line-items, for which the response must be researched and identified. Often, an individual engineer will only be responsible for the data related to a small sub-set of those line items. This means that the engineers responding to the Compliance Matrix will frequently lack a holistic view of the entire system. The lack of a “holistic view” of the system can add overall program risk because the implications of one requirement on another may not be understood until much later in the design process.

Successful system design requires a holistic view of the entire system architecture and Power Input envelope. This involves understanding the matrix as a whole and how any given requirement can affect numerous other variables. Navigating through the thicket of the many different international Input Power specifications can be both time-consuming and confusing. To help guide the reader though this demanding process, we have collected the most pertinent Input Power specifications for each of the most important international military standards and in this paper we provide that information in tabular form.

While we have done the significant “legwork” needed to assemble this data, it’s important to understand that the next phase of system design, making sense of the requirements and finalizing critical design decisions, demands a full understanding of the system architecture and the implications of the various requirements.

The complex world of international military standards

Adding to the challenge of ensuring that a system’s Input Power is in compliance with a given military specification is the fact that there are many different military standards in use today. It is not unusual for military system designers to confront the need to compare a component designed to a specific US military specification, such as MIL-STD-1275, with one designed to conform to a EUROCAE coordinated standard, such as RTCA DO-160, or a UK standard such as DEF-STAN 61-5 part 6. For example, avionics equipment may need to be in compliance with MIL-STD-704 and DO- 160. While connected electrical equipment may require compliance with MIL-STD-1275 and DEF-STAN 61-5 part 6, other military systems may need to comply with MIL-STD-461 for electromagnetic interference.

One of the benefits of being able to compare two different military standards is that the data can help identify and ensure a pre-existing compliance with an existing solution. This can result in time and cost savings, since it enables the use of the existing solution to meet the needs of the new design requirement.

Cutting through the thicket

While the information in this Reference Guide can help with the task of completing an Input Power Compliance Matrix, the reader should keep in mind that a system design partner like Curtiss-Wright deals with these very complex standard compliance issues on a daily basis. Instead of taking on the often difficult, lengthy and costly process of searching for and “translating” the many different Input Power specifications on their own, the system engineer should consider working with a system design partner to take advantage of their extensive experience and expertise. In many cases a pre-validated and fielded commercial-off-the-shelf (COTS) solution will already be available as an alternative to designing a new system from scratch. The System Design Partner’s expertise in “reading across” the military standard specifications, working with a holistic system view, can eliminate critical program delays or compliance issues. This approach can greatly reduce program risk, schedule time and costs.

Input power specifications for leading international military

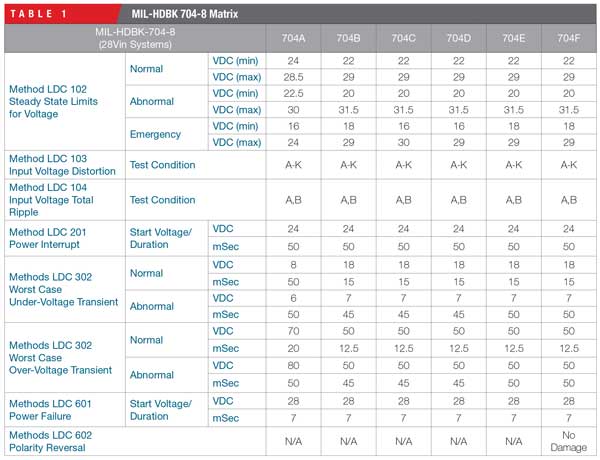

MIL-HDBK-704-8: 28VIN Systems

Table 1 addresses MIL-STD-704 Input Power requirements for 28 Vin Systems.

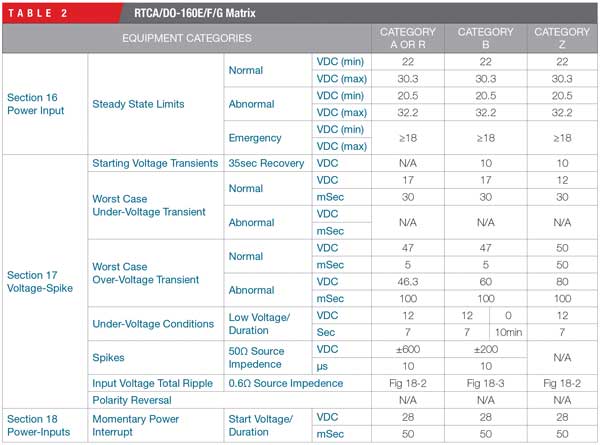

RTCA/DO-160E/ F/G

Table 2 provides the minimum standard and the degree of confidence in the performance characteristics for environmental test categories for airborne equipment in compliance with DO-160.

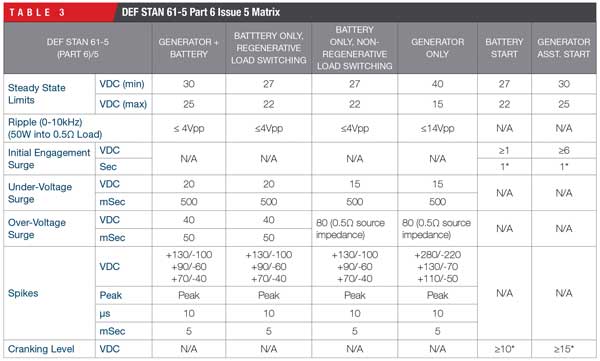

DEF STAN 61-5 (Part 6)/5: 28V and Ground Vehicle Power Supplies

Table 3 addresses electrical compatibility between ground vehicle power supplies and installed equipment for 28 V systems for compatibility with DEF-STAN 61-5 requirements.

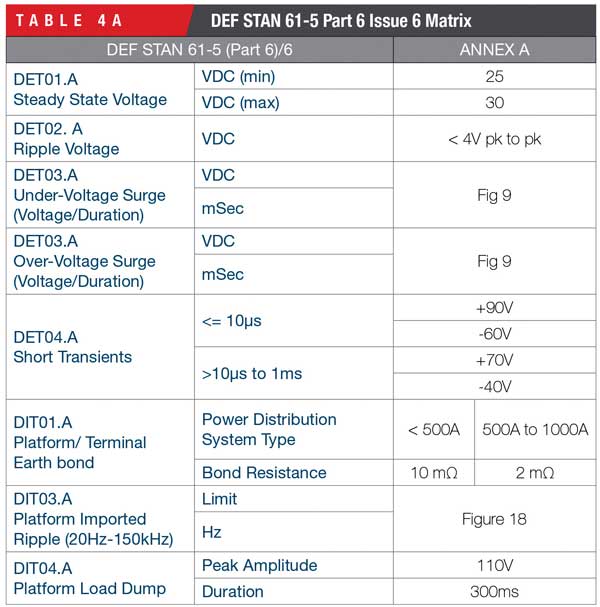

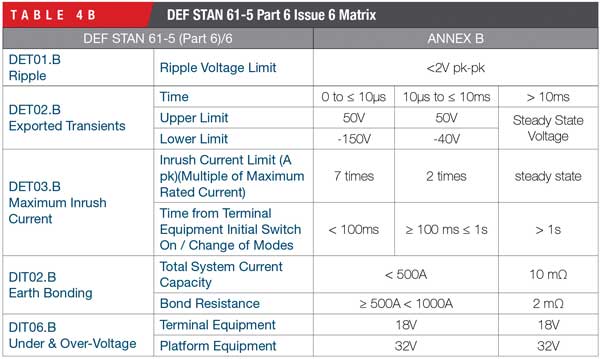

DEF STAN 61-5 (Part 6)/6: Power Distribution

Tables 4a and 4b address the power distribution requirements and constraints for Platform and Terminal Equipment. It covers system military (ground) platform dc power distribution systems, platform and terminal equipment, military off the shelf (MOTS) and commercial off the shelf (COTS) vehicular environments.

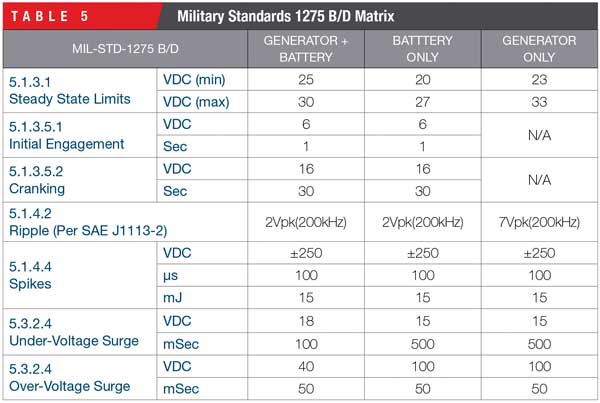

MIL-STD 1275 B/D: Steady State and Voltage Duration

Table 5 addresses the limits of steady state and voltage duration characteristics for military ground vehicles in conformance with MIL-STD-1275.

MIL-HDBK 704-7: 270 Vin Systems

Table 6 addresses the limits for equipment to ensure compliance with the electric power characteristics of MILHDBK-704-7.

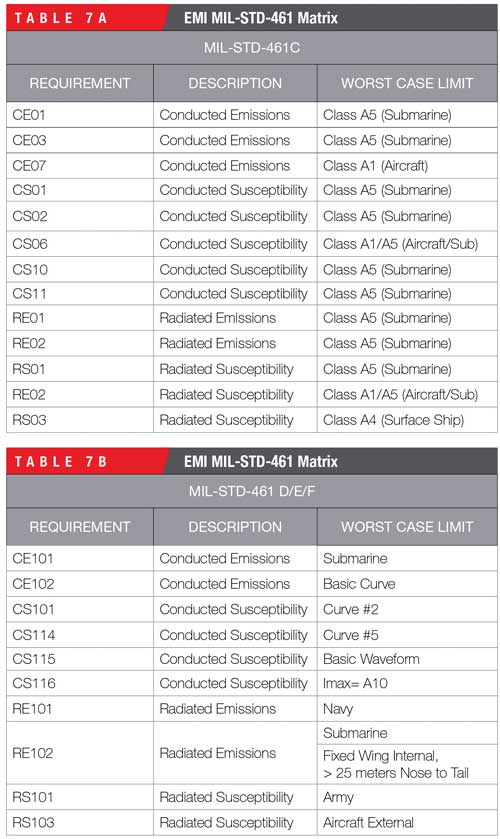

MIL-STD-461C and MIL-STD- D/E/F: 28 V and Ground Vehicle Power Supplies

Tables 7a and 7b address the EMI requirements for compliance with MIL-STD 461.

Advertisement