Any object able to fit inside a one-inch diameter cylinder is rendered invisible, boasts Robert Schittny and his colleagues from Karlsruhe Institute of Technology in Germany. The team have developed one of the first light-bending invisibility cloaks made from commonly available items such as acrylic paint and polymers.

To achieve invisibility, scientists must experiment with a multitude of manmade light-refracting metamaterials in order bend light around the object that’s being hidden, before restoring the beam to its original, unaltered state. The end result creates the illusion that light traveled in a straight line, never straying. But unfortunately, the majority of cloaks thus constructed cannot achieve complete invisibility, instead, only shielding objects from single segments of the visible light spectrum such as red.

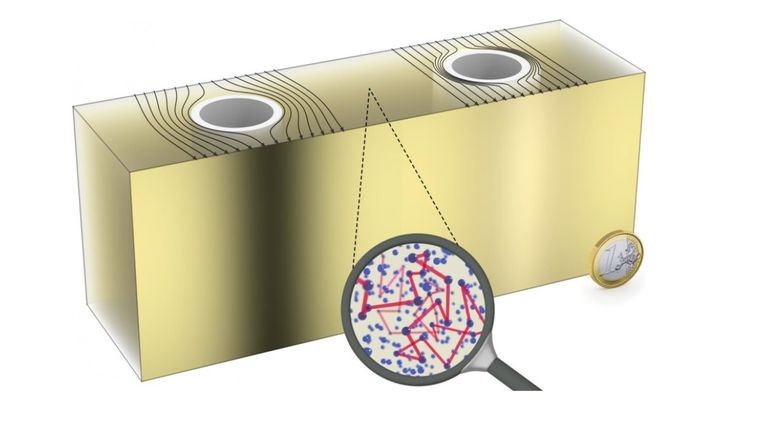

Through a unique composition of polydimethylsiloxane, a polymer used in shampoos and contact solution, infused with nanoparticles of titanium dioxide, Robert Schittny and his team report that they’ve managed to not just completely obfuscate objects visible to the naked eye, but have created a working model for demonstration purposes. Their model, unlike those made of metamaterials, scatters light rather than refracts it.

“It is a macroscopic cloak that you can look at with your bare eyes and hold in your hands,” says Schittny. “With a reasonably strong flashlight in a not too bright room, it is very easy to demonstrate the cloaking. That means no fancy lab equipment, no microscopes, no post-processing of measurement data. The effect is just there for everyone to see.”

Scattering permits light rays to simultaneously exit the cloak in the same direction they arrived by slowing down the speed at which the beam circulates within the cloak, before accelerating its departure to make up for the longer path needed to travel.

Although the military implication of such a device is obvious, Schittny hopes it’ll find purpose in classroom education as a means of exciting students about physics.

Source: Gizmag

Advertisement

Learn more about Electronic Products Magazine