By Junko Yoshida, global co-editor-in-chief, AspenCore Media, chief international correspondent, EE Times

Consumers (and the media) expect to be wowed by Apple every year with the rollout of the latest iPhone and Apple Watch iterations. Apple occasionally disappoints, but not this year; Bloomberg just called iPhone 11 Pro “the world’s best phone camera,” declaring that “iPhone reclaims the title of mobile camera champion.”

It's not that we here at EE Times are unimpressed by the latest iPhone features, but if you want to see us really geek out, crack the thing open.

We uncovered several curious but smart design choices made by Apple for its new iPhones, as well as for the new Apple Watch. Among the changes is Apple’s transition from two-sided PCB to stacked PCB in the iPhone 11. Also, there’s a camera upgrade and a new monolithic battery inside the iPhone 11 Pro. And Apple has removed the iPhone’s pressure touch display.

EE Times received expert help from System Plus (Nante, France), a partner company of Yole Développement (Lyon, France). System Plus beefed up its teardown capabilities by acquiring earlier this year an Austin, Texas-based teardown business previously owned by ABI Research. This Austin group even subjected the new iPhones and Apple Watches to CT scans. It examined chips and other new design elements inside the systems to conduct detailed technology and business analysis.

UWB module

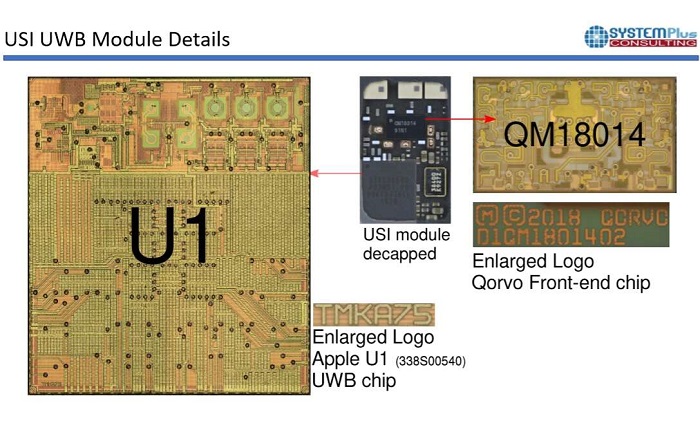

As soon as we learned that Apple is the first company to integrate UWB technology into smartphones, we got curious about Apple’s UWB chip. Apple’s ad claims that the UWB technology inside its new iPhones is enabled by a UWB chip the company describes as an “Apple-designed U1 chip.”

We asked System Plus about not just the U1 chip, but who is responsible for the whole UWB module inside the new iPhones.

(Image: System Plus)

Jim Mielke, vice president, Teardowns at System Plus Consulting, confirmed, “Our estimate is that Apple did indeed do the UWB chip.” Further, he revealed that the UWB module was put together by Universal Scientific Industrial (Shanghai) Co., Ltd., (USI), which integrated the Apple custom UWB chip U1 and Qorvo’s complex switch/frontend.

Stacked PCB

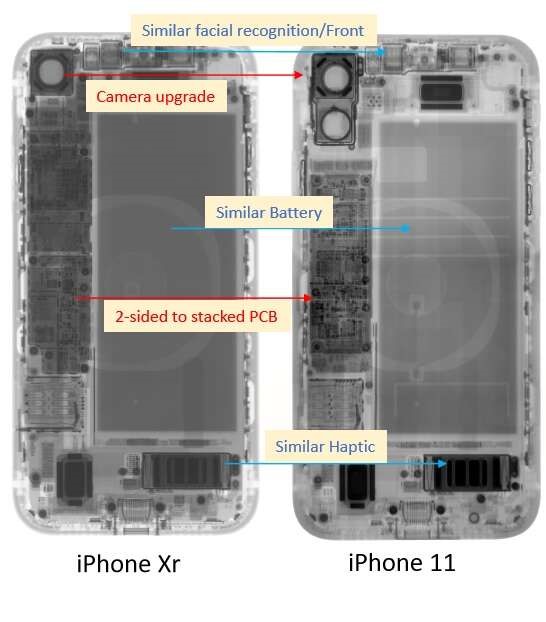

The marked difference between iPhone Xr and the iPhone 11 is a transition from a 2-sided to a stacked PCB. This advance helps create the room for an additional camera and the UWB module.

(Image: System Plus)

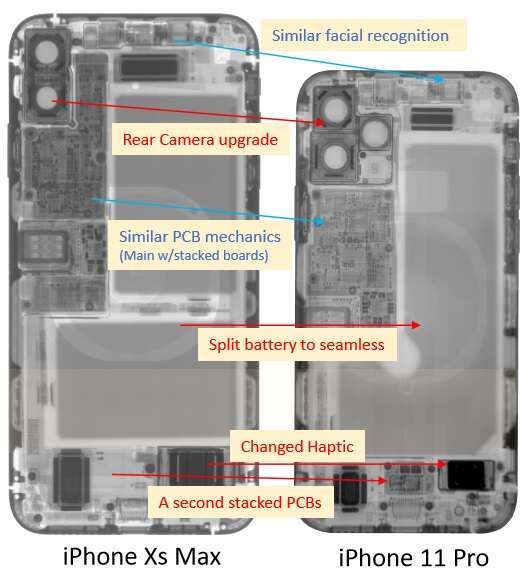

Comparing iPhone Xs MAX with the new iPhone 11 Pro, both handsets use similar PCB mechanics with a stacked PCB as its main board. System Plus, however, found that iPhone 11 Pro is using a second stacked PCB.

Monolithic battery

One of the most notable features of the iPhone 11 Pro was revealed by an X-ray scan that reveals Apple is now using a seamless battery instead of what was, in the iPhone Xs MAX, a split battery.

(Image: System Plus)

Changed haptic

One big discovery is that Apple dropped the “pressure touch display” altogether in iPhone 11 Pro.

It’s important to note that iPhone, known for its use of capacitive touch screens instead of resistive technology for a long time, had already moved away from a capacitive touch screen to a resistive screen when it transitioned from iPhone 8 to iPhone X.

While the resistive version remained in iPhone Xs, that model was its swan song. The resistive technology was completely removed from iPhone 11/11 Pro.

But why did Apple drop “force touch” — an Apple-developed technology?

Force-touch technology, called 3D Touch on iPhone models, was supposed to add improved usability to software by offering a third dimension to accept input. The idea was, “if you press harder, it was supposed to do different things,” explained System Plus’ Mielke. But in the end, it appears that Apple couldn’t find novel applications for this tactile feedback, and ended up dropping it entirely.

For the complete article visit sister publication EE Times.

Advertisement

Learn more about Electronic Products Magazine