To read Part 1 of this article, please click here.

Humanitarian Efforts for the People of Kisengo

In order to build the strong social components necessary to creating a long-term workable solution, KEMET committed $1.5 million over the Partnership’s first two years for social and economic sustainability projects at the mine and village. The Partnership teamed with Kisengo Foundation (KF), which is responsible for defining the needs of the community, the individual projects, and therefore, how the money is spent. Projects already in progress or completed include a school, a medical clinic, fresh water wells, solar street lighting, and more. KEMET anticipates that the Partnership’s social programs will be self-sustaining in the long run, using proceeds from the mine output.

KEMET committed $1.5 million over the Partnership’s first two years for social and economic sustainability projects at the mine and village.

This local school is being built as part of this initiative.

However, it is not enough to simply build a school or a medical clinic—it is just as important to find teachers and doctors who are willing to live at the site. And systems must be developed to guarantee they are paid and that they have the tools they need to do their jobs. In September 2012, doctors from the Upward Africa Project, a private medical foundation in New Jersey, U.S.A., traveled to the DRC to train local and regional doctors on the prevention and treatment of musculoskeletal and spinal injuries, the most frequent type of injuries found at mine sites. This was the first of many visits by these and other physicians in the effort to enhance the overall quality of life for the people of Kisengo.

Securing the Supply Chain

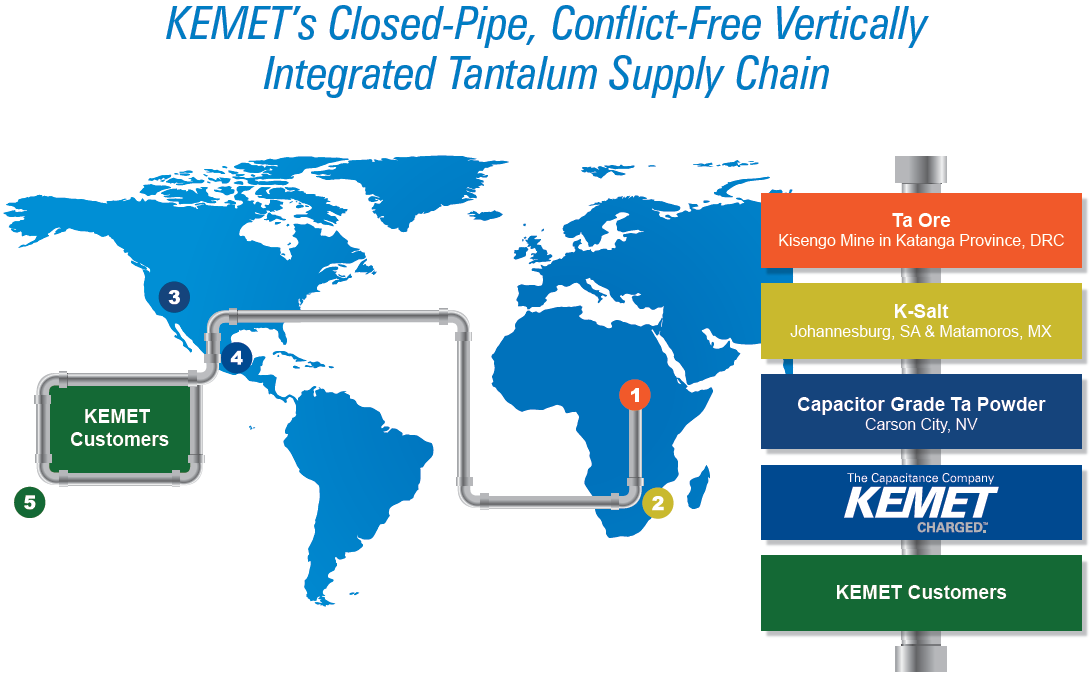

The overall goal of the KEMET project was to create a closed-pipe, conflict-free, vertically integrated tantalum supply chain. The first lots of ore from the Kisengo mine were shipped to a certified Electronics Industry Citizenship Coalition (EICC) conflict-free smelter to produce tantalum powder. But to ensure a more efficient closed-pipe system and complete its vertical integration strategy, KEMET needed access to facilities for tantalum ore processing and capacitor-grade tantalum powder manufacturing.

To this end, KEMET agreed to acquire the sole output rights of Tantalite Resources in Johannesburg, South Africa, and also secured a tantalum powder manufacturing facility in Carson City, Nevada, U.S.A. Named KEMET Blue Powder, this tantalum powder facility has the ability to manufacture a major portion of KEMET’s tantalum powder requirements, both on a volume and powder type basis. Both facilities are compliant with the EICC/ Global e-Sustainability Initiative (GeSI) Tantalum Conflict-Free Smelter (CFS) program.

Moving Forward!

KEMET has shown us and the industry that sourcing conflict-free materials is a complex but necessary process from both ethical and legal perspectives. With the Partnership for Social and Economic Sustainability, KEMET has focused on the social and economic essentials necessary to create a sustainable environment for all stakeholders in the overall tantalum supply chain. It begins with the miners and their families, and ultimately ends with KEMET customers and shareholders.

Companies involved in similar supply chains have a head start in developing initiatives that begin to resolve the issues resulting in conflict and human atrocities. In September 2012, the U.S. Securities and Exchange Commission (SEC) issued a final ruling on Section 1502 of the Dodd-Frank bill. The final ruling document referenced the KEMET solution a total of six times – a significant indication of the impact that the company’s efforts have already had and the roadmap those efforts represent for other manufacturers to follow.

—–

Suzanna Brooks joined Mouser Electronics in 2011 as a Technical Content Specialist and writes web content about the newest embedded and optoelectronic products available. Suzanna holds a Bachelor of Science degree from Embry-Riddle Aeronautical University and is a private pilot.

Suzanna Brooks joined Mouser Electronics in 2011 as a Technical Content Specialist and writes web content about the newest embedded and optoelectronic products available. Suzanna holds a Bachelor of Science degree from Embry-Riddle Aeronautical University and is a private pilot.

Advertisement

Learn more about Electronic Products MagazineMouser Electronics