Motor control plays an important strategic role in the technological development of Industry 4.0. One key concern in industrial development is energy usage. Electricity consumption is growing significantly due in part to the electrical demand of industrial electric motors. As a result of these growing demands, the search for efficient solutions in the field of motor control is a priority for developers and component manufacturers alike.

Along with energy consumption, design complexity is increasing due to the stringent control requirements involving many electronic technologies that require significant efforts. One example is the use of wide-bandgap (WBG) materials.

From a functional point of view, motor control consists of several levels. For example, motion control requires the execution of very sophisticated and computationally intensive control algorithms. Motor control covers a wide range of applications, from the simple control of fans and pumps to the more complex problems of industrial control, including robotics and servo mechanisms. Here, we take a look at the key components of a motor control system.

Motors and drivers

DC motors are the most common, as they are cheaper and consist of a stator (fixed part) — i.e., the permanent magnet — and a moving part (the rotor), which houses the winding connected to the commutator that supplies the current. The speed control of the motor is achieved by regulating the direct current. For this purpose and depending on the nature of the application, full-bridge, half-bridge, or step-down converters are used to drive the DC motor.

An AC motor basically consists of a transformer with the primary section connected to the AC voltage and the secondary section, which conducts the induced secondary current. Microprocessor-based electronics, an inverter, and signal conditioning are used to control the speed of this motor.

The controller is an electronic device that acts as a “brain” in a control system. The number of controllers used varies based on the amount of individual processes that need to be controlled. For a complex system, there may be numerous controllers. Each of these controllers can send commands to the motors and, at the same time, receive instructions from the actuators themselves.

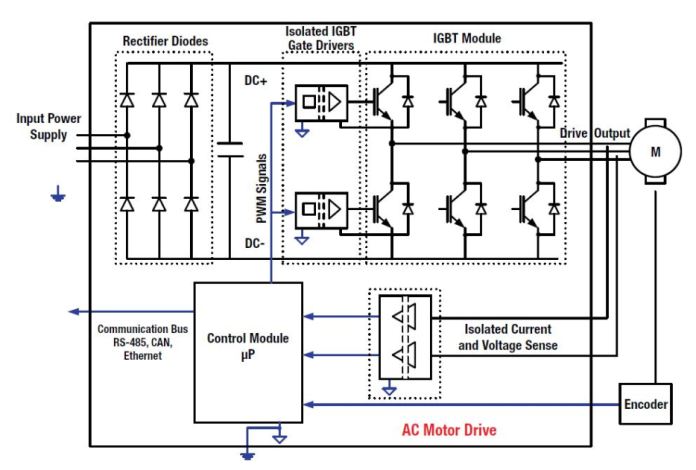

Robotic systems used in industrial applications mainly use three-phase motors powered by alternating voltage (AC). As an example, Fig. 1 shows the block diagram of an electronic control circuit in which a dedicated microcontroller (MCU) generates a PWM signal. As an alternative to the MCU, DSP or FPGA solutions are more suitable for implementing complex digital filtering algorithms.

Fig. 1: Block diagram of an AC-powered three-phase induction motor control (Source: Texas Instruments)

A controller example for DC motors is Trinamic’s TMCM-1637 5- A RMS and TMCM-1638 7-A RMS slot-type modules with two field-oriented controller/drivers that add Hall and ABN encoder functionality for field-oriented control (or vector control). These modules support single-phase DC motors, two-phase bipolar stepper motors, and three-phase brushless DC (BLDC) motors (Fig. 2).

IGBTs

Insulated-gate bipolar transistors (IGBTs) embody a real innovation in electrical power control electronics. As switching solutions, the innovation comes from the high switching frequency. IGBTs represent the basic functionality of electrical power control devices that are well-suited to solving complex motor control problems.

The latest solutions have developed an excellent relationship between switching speed and stability of behavior in particularly extreme use conditions, such as in the automotive sector when implementing inverters to drive electric motors. One example is the 1,200-V IGBT S series from STMicroelectronics. These IGBTs are optimized for use at low frequencies (up to 8 kHz) and are characterized by a low Vce(sat). The 1,200-V IGBT S series is based on third-generation trench-gate field-stop technology.

GaN and SiC

However, WBG materials, gallium nitride and silicon carbide, are making inroads in motor control applications as a replacement for silicon-based devices. In power electronics, the main advantages offered by WBG materials include lower power losses, higher efficiency, higher switching frequencies, more compact size, higher operating temperature (well beyond the 150°C upper limit achievable by silicon), greater reliability under difficult operating conditions, and high breakdown voltages.

For example, the higher electron mobility of a GaN high-electron–mobility transistor (HEMT) translates into a greater switching speed, as the charges that normally accumulate in the joints can be dispersed more quickly. The faster rise times, lower drain-to-source on-resistance (RDS(on)) values, and reduced gate and output capacitance achievable with GaN all contribute to its low switching losses and ability to operate at switching frequencies up to 10× higher than silicon.

Reducing power losses brings additional benefits, such as more efficient power distribution, less heat dissipation, and simpler cooling systems. Many motor control applications require a fan to provide forced air cooling to operate within the safe operating limits of the device. By using GaN, power dissipation can be reduced and enable “fan-less” operation, which is particularly important in low-weight applications such as electronic drones.

In industrial power applications, electronic designers can achieve benefits by also using SiC MOSFETs, which offer significant efficiency improvements, smaller heat-sink size, and lower cost than traditional Si-based solutions such as IGBTs. SiC technology achieves a very low RDS(on) per unit area, high switching frequencies, and negligible energy losses during the reverse-recovery phase that occurs following the turn-off of the body diode.

The use of SiC devices in motor control and electrical power control applications is a real breakthrough thanks to features such as energy savings, size reduction, higher integration, and reliability. These features make them well-suited for high-reliability sectors such as automotive and industrial automation control.

In industrial drives, particular attention must be paid to turn-on and turn-off commutation speeds. As a matter of fact, SiC MOSFET dV/dt can reach much higher levels than IGBTs. If not properly addressed, high-commutation dV/dt increases voltage spikes over long motor cables and might generate common- and differential-mode parasitic currents that, over time, introduce failures in winding insulation and motor bearings. Even though faster turn-on/-off improves efficiency, the typical dV/dt in industrial drives is often set at 5 to 10 V/ns for reliability reasons.

A comparison conducted by STMicroelectronics on two similar 1.2-kV power transistors — a SiC MOSFET and a Si-based IGBT — has proved that the SiC MOSFET device can guarantee much less energy loss for both turn-on and turn-off, in comparison with the Si IGBT, even under the imposed conditions of 5 V/ns (Fig. 3).

The use of SiC devices in motor control and electrical power control applications in general is a real breakthrough thanks to features such as energy savings, size reduction, integration opportunities, and reliability. Among other options, it is now possible to use the optimum switching frequency in the inverter circuit for the connected motor, which leads to important advantages in motor design.

For example, Infineon Technologies’ SiC-based CoolSiC MOSFETs with .XT interconnection technology in a 1,200-V optimized D²PAK-7 SMD package enables passive cooling in power-density–critical motor drive segments like servo drives, thus supporting the robotics and automation industry in implementing maintenance-free and fanless motor inverters (Fig. 4).

In automation, fanless solutions enable new design opportunities, driven by the fact that they save costs and effort on maintenance and materials. Infineon’s CoolSiC trench MOSFET chip solution with .XT interconnect technology offers attractive thermal capabilities in a small form factor, making it well-suited for drive integration in a robotic arm, as an example. The CoolSiC MOSFET SMD devices have a short-circuit withstand time of 3 µs and are rated from 30 mΩ up to 350 mΩ. This meets the requirements of servo motors.

Microcontrollers

Motor control solutions consist of hardware and software components. The hardware component is electronic control devices such as IGBTs, SiC and GaN MOSFETs, power diodes, etc., while the software component addresses the control of the hardware, which is becoming increasingly complex and sophisticated. The availability of computing architectures that are optimized for the control and management of power devices allows developers to obtain performance that would otherwise not be possible in the control field.

A couple of examples come from NXP Semiconductors and Renesas Electronics. NXP’s MPC57xx family of 32-bit processors is based on Power Architecture technology for automotive and industrial powertrain applications in addition to other automotive control and functional management possibilities. The processors offer AEC-Q100 quality, on-chip security encryption protection for tamper-proofing, and support of ASIL-D and SIL-1 functional safety (ISO 26262/ IEC 61508). They provide Ethernet (FEC), dual-channel FlexRay, and up to 6 SCI/8 DSPI/2 I2C for different communication protocols.

Renesas offers the RA6T1 32-bit MCUs based on the Arm Cortex-M4 core to operate at 120 MHz with a collection of peripherals optimized for high performance and precision motor control. A single RA6T1 MCU can simultaneously control up to two BLDC motors. In addition, the Google TensorFlow Lite Micro framework for TinyML applications adds enhanced failure detection to the RA6T1 MCUs, offering customers an intelligent, easy-to-use, and cost-effective sensorless motor system for predictive maintenance.

Motor requirements vary depending on the application, which may need to be optimized and fine-tuned for a specific use case. The market provides several solutions in terms of IGBTs, WBG semiconductors, and MCUs to meet those requirements. However, new hardware needs to be developed that offloads real-time critical tasks from the processor, while enabling more diagnostics, predictive maintenance and AI, and functional safety systems.

Advertisement

Learn more about Infineon TechnologiesSTMicroelectronicsTexas InstrumentsTRINAMIC