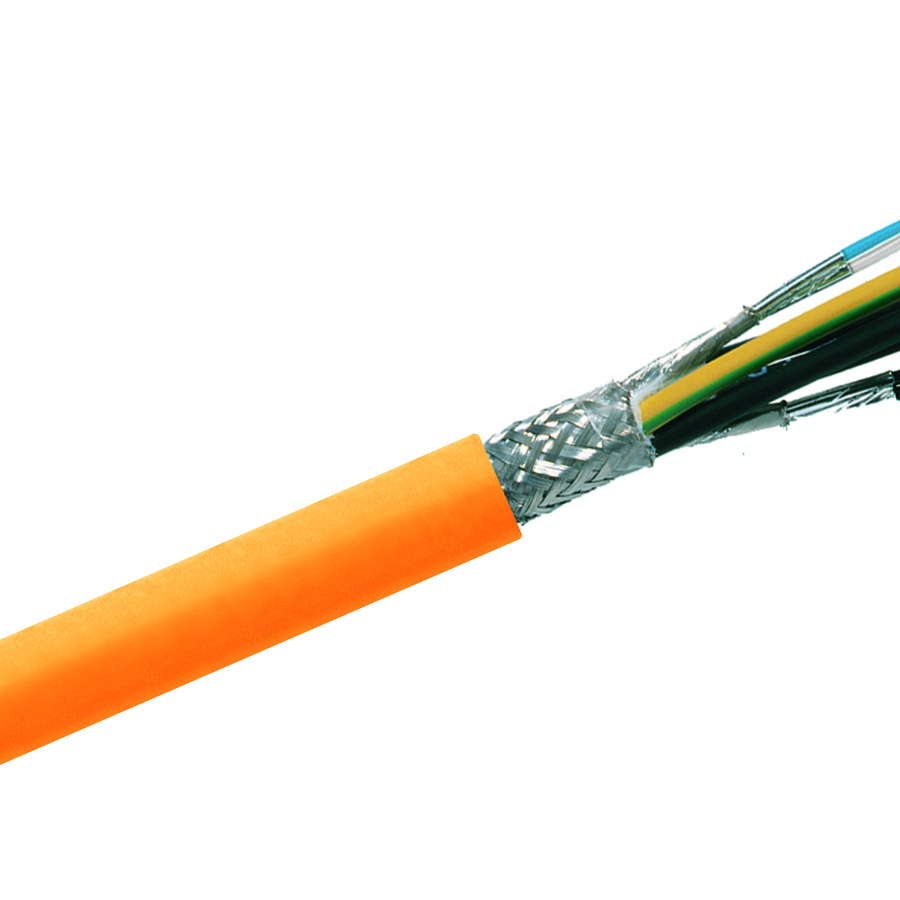

The Lapp Group has developed two new hybrid servo cables designed to meet the requirements of the emerging HIPERFACE DSL control architecture. The OLFLEX SERVO FD 7DSL features a polyurethane jacket for use in cable tracks, while the OLFLEX SERVO 7DSL from Lapp is PVC jacketed for fixed installations. Both products meet HIPERFACE DSL standards and have UL AWM approvals.

Hybrid servo cables tend to use either PVC or polypropylene core insulation systems. Lapp’s new servo cables have a polypropylene insulation, which delivers better electrical properties than PVC. The superior electrical properties mean that polypropylene insulation can be substantially thinner than PVC for a roughly 20% reduction in overall cable diameter.

According to Lucas Kehl, product manager at the Lapp Group, servo system designers have traditionally not paid much attention to the cost of the cabling. Says Kehl, “The upfront and lifetime costs associated with power and signal cables can represent a significant portion of the total outlay for a servo system. And the smaller the servo system, the more the cable costs matter. Fortunately, the up and coming new HIPERFACE DSL control architecture can reduce the lifetime costs of servo cabling by more than 35%.”

HIPERFACE DSL is a digital servo architecture that uses a single hybrid servo cable for both power and signal. This cable contains a shared signal pair for the motor feedback and temperature signals, both of which are modulated for transmission. This streamlined approach to cabling eliminates the need to buy, install and maintain standalone encoder and resolver cables.

Both of Lapp’s new hybrid servo cables are resistant to temperature extremes, oil and flame. OLFLEX SERVO FD 7DSL additionally resists UV light and offers a tight bend radii that can facilitate smaller, more economical cable tracks.

Advertisement