MIT’s Photonic Microsystems Group is developing a LIDAR-on-a-chip system that’s smaller than a dime, has no moving parts, and could be mass-produced at a low cost to be used in robots, drones, and self-driving cars. Light detection and ranging, or LIDAR, is a sensing technology based on laser light. Simply put, it’s similar to radar, but can have a higher resolution since the wavelength of light is about 100,000 times smaller than radio wavelengths.

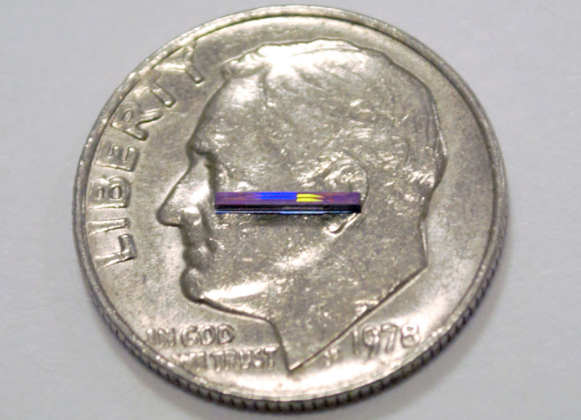

With a LIDAR sensor that fits on a 0.5 mm x 6-mm chip, the team predicts the technology will cost as little as $10 to manufacture at scale. Image source: IEEE Spectrum.

For a machine such as a robot, LIDAR is important. Since radar isn’t capable of accurately imaging small features, a robot equipped with only a radar module would have a difficult time grasping a complex object. Currently most LIDAR applications are autonomous vehicles and robotics, but also include terrain and ocean mapping and UAVs. Such applications depend heavily on LIDAR, and an expensive module is a major obstacle to their use in commercial products. Today’s high-end models typically cost tens of thousands of dollars, and even the smallest systems are the size of a hockey puck. MIT and DARPA have collaborated with plans to take these large, expensive, mechanical systems and integrate them on a microchip that can be mass produced in commercial CMOS foundries. According to MIT, this new version of LIDAR will shrink the light-bouncing apparatus onto a chip that’s smaller than a grain of rice.

Researchers Christopher Poulton and Michael Watts claim their prototype sensors “promise to be orders of magnitude smaller, lighter, and cheaper than LIDAR systems available on the market today.” They could possibly be the eyes of future robots.

The base of this new-found technology is a discipline called silicon photonics, which is when engineers create miniature circuits that guide and steer light on a microscopic level. Poulton and Watts compared it to the fabrication of microchips, which shrunk electronic systems that used copper wire and components onto smaller transistors.

With a LIDAR sensor that fits on a 0.5 mm x 6 mm chip, the team predicts the technology will cost as little as $10 to manufacture at scale. These chips have a number of limitations, including a narrow field of view and a short range (they can 'see' distances of two meters), but those involved say these properties could be quickly improved.

Source: IEEE Spectrum

Advertisement

Learn more about Electronic Products Magazine