By Gina Roos, editor-in-chief

Texas Instruments (TI) has expanded its temperature-sensing portfolio with the introduction of a new family of linear thermistors that deliver up to 50% higher accuracy compared with negative temperature coefficient (NTC) thermistors. The higher accuracy of the thermistors enables operation closer to the thermal limits of the other components and the overall system, which helps reduce the bill of materials (BOM) and total solution cost, said TI. Other benefits over NTC thermistors include the elimination of additional linearization circuitry, minimized calibration, less resistance tolerance variation, higher sensitivity at high temperatures, and simplified conversion methods.

What’s significant about TI’s linear thermistors is that they are the industry’s first to provide the accuracy of a linear thermistor at a similar size and cost of an NTC thermistor.

“Price is one of the biggest selling points for our linear thermistors,” said Will Cooper, temperature & humidity sensing marketing and applications manager, Texas Instruments. “Not only can you avoid the hidden costs associated with compensating for an NTC’s performance — most notably the need for additional components and linearization circuity and to calibrate at more than one point — but our devices are available at a price point of $0.05 in 1,000-unit quantities, which is similar to the price of comparable NTCs (i.e., those providing 1% resistance tolerance).”

NTC thermistors offer a low price, but engineers often face several design challenges, depending on the application, which include degraded performance at temperature extremes and complex calibration, which impacts design time.

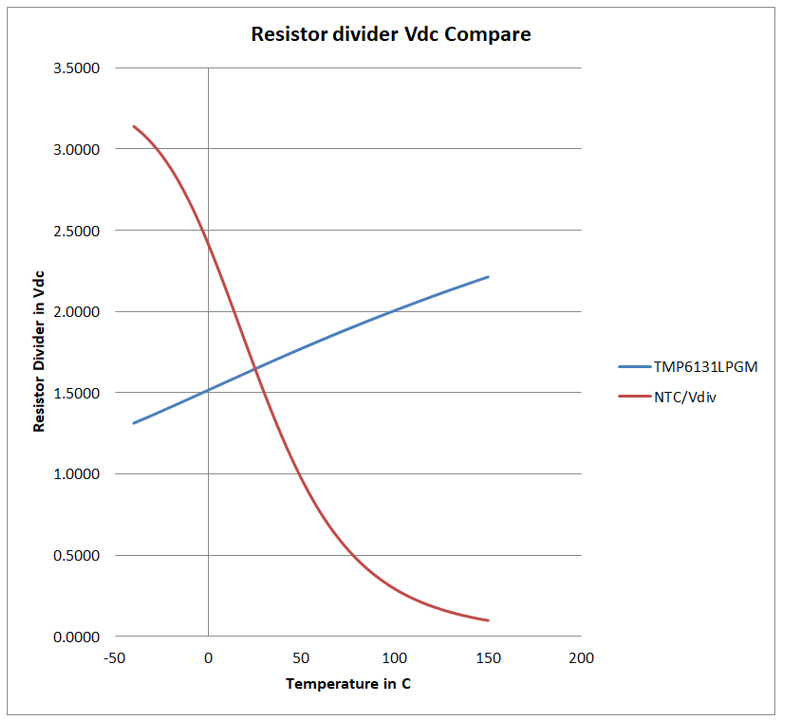

“NTC thermistors have a non-linear slope that will lead to lower sensitivity than a linear thermistor at some point,” explained Cooper. “While this varies by NTC, in most cases, this happens between 65°C and 75°C. At that point, assuming the same analog-to-digital converter (ADC) resolution and resistance tolerance, and assuming that the customer calibrated both thermistors at the point of interest, NTC thermistors will offer lower temperature accuracy. Now, if an engineer calibrates at 25°C, the error with respect to the NTC would be even greater due to the non-linearity.

“In high-temperature applications above 80°C, the resistance drops and current consumption (power) increases as the NTC gets hotter,” he said. “In the same scenario, our linear thermistors stay much more consistent across temperature while actually decreasing current consumption in high-temp environments” (see Fig. 1 ).

This means that the linear thermistors offer more accurate thermal measurements, particularly at temperatures above 80°C, making them well-suited for industrial, automotive, and consumer applications in which real-time temperature readings are needed for system performance and protection.

“For example, motor, battery pack, and automotive powertrain systems need accurate, real-time temperature readings to deliver optimal performance and overheating protection,” said Cooper. “NTC thermistors really aren’t ideal for these systems due to their low sensitivity and high resistance tolerance at temperature extremes. They simply can’t measure temperature accurately at temperatures above 80°C.”

In addition, the linear thermistors can be used for systems requiring multiple temperature range measurements — like adjusting a display backlight as temperature changes and shutting off the system if it gets too hot, said Cooper. “The high linearity provided by our thermistors enables engineers to calibrate at one point, rather than the two to three points of calibration that are typically needed when designing with an NTC. Only needing to calibrate once with a linear thermistor provides several benefits — namely, simplified design, increased system performance, and lower total system cost.”

But like any technology, there are tradeoffs that engineers have to consider.

When considering whether to use an NTC or linear thermistor, design engineers have to take into account price, size, and temperature accuracy, said Cooper.

“NTC thermistors are typically one-tenth the size and a third of the price as a linear thermistor, but those savings come at the expense of accuracy across the full temperature range,” he said. “Having said that, NTCs provide better sensitivity at 25°C, so they’re a solid option for applications that operate closer to room temperature. But if high overall accuracy is the goal, a linear thermistor is the better option.”

Engineers can use TI’s thermistor design tool, available on the thermistor product pages and datasheets on TI.com, to calculate temperature resistance values and kickstart their design with example conversion methods and code.

The linear thermistors also reduce printed circuit board (PCB) layout by about 33% compared with NTC thermistors because they eliminate the need for additional linearization circuitry or redundant NTC thermistors. They also are one-tenth the size of similar silicon-based linear thermistors, thanks to their availability in traditional passive component 0402 and 0603 package sizes.

TI offers the linear thermistors in the same packages as traditional passive thermistors to make it easier for system designers and procurement teams to design them into their designs.

“Additionally, the 0402 package is one of the most widely used packages for space-constrained designs, which provides a size advantage in terms of thermal mass and ultimately increases response time,” said Cooper.

The TMP61 , TMP63 , and TMP64 devices are available now through TI and authorized distributors with starting prices as low as $0.05 in quantities of 1,000. The devices are offered in through-hole packaging and surface-mount 0402 and 0603 footprint options. An evaluation module, the TMP6EVM , is available.

Advertisement

Learn more about Electronic Products MagazineTexas Instruments