By Alix Paultre, contributing editor

We are living in one of the best times ever to be in the power electronics industry. Very powerful forces have been moving power technology forward in a pace unseen since electricity was first commercialized. Once upon a time, the power system was the last thought in an advanced electronic systems design; now, power technology is the first consideration. Power management is no longer just a cost issue. The way that your product handles its energy can mean the difference between success and failure in today’s marketplace.

The revolution began with the commercialization of switching power systems just a few decades ago, then ramped up with the advent of digital power, and now is running full bore with the addition of new semiconductor materials and new power topologies enabled by these various complementary advances. It is obvious to even the most jaded industry observer that power is now a major factor in electronic systems design today.

This new love affair with power electronics has come about for multiple reasons. Portable devices like smartphones and tablets put a renewed emphasis on battery storage and system efficiency, as the two are inextricably linked. This pressure increased by an order of magnitude with the advent of the electric vehicle revolution, partly fueled by, and now dependent upon, advances in power electronics in the areas of efficiency and power density previously unimagined. Add to that the realization that even tethered equipment can save a facility owner insane amounts of money, and you have the foundation for a new renaissance in power systems.

New materials

A lot has been said about wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), and until recently, most of it was promise and promotion. However, in the last couple of years, both GaN and SiC have come out strongly as a viable and improved alternative to silicon in advanced power applications.

One of the issues with any new solution is compliance with industry standards. This criticism is fading in strength as more and more devices are qualified. For example, Efficient Power Conversion (EPC) recently met the AEC-Q101 qualification with two of their eGaN devices, enabling them to address applications in automotive and other harsh environments.

The EPC2202 and EPC2203 are discrete transistors in wafer-level chipscale packaging and will soon be followed with several more discrete transistors and integrated circuits designed for the harsh automotive environment. GaN is emerging as a critical core technology in vehicle systems.

Another issue is that these devices are so new that many engineers have no experience working with them, so development kits and reference designs are vital to market acceptance. Addressing this aspect, Transphorm recently released a complete 3.3-kW continuous conduction mode bridgeless totem-pole power factor correction reference design for high-voltage (HV) GaN power systems.

Image source: Transphorm.

Image source: Transphorm.

Based on Transphorm’s 650-V GaN platform of JEDEC and AEC-Q101 HV GaN transistors, the reference design delivers 99% efficiency in a TO-247 power package. The TDTTP3300-RD kit includes all of the resources required, including both hardware and firmware design guides (with downloadable firmware), design schematics, bill of materials, and Gerber files.

Topologies and packaging

Of course, better discrete components are only a part of the equation. Sticking SiC into a TO-220 package will give you some improvement, but the performance increase may not be cost-effective due to the higher price point. The only way to truly harness the potential of these new materials are with new, low-parasitic packages and advanced topologies that take optimum advantage of the performance offered by these next-generation materials.

At the driver level, there are already chips available to properly drive GaN and SiC transistors. This is a critical point, as an improperly driven device cannot perform as desired. One way to address the issue is with an on-chip driver, which is tailored to match electronically and physically to maximize efficiency in output and footprint.

An example is monolithically integrated GaNFast technology from Navitas , an on-chip topology that provides a direct connection between the control IC’s digital PWM output and the driver’s PWM input, with precise internal voltage regulation and no parasitic path to the GaN FET gate. With propagation delays down to 5 ns and a robust dV/dt up to 200 V/ns, GaNFast power ICs almost eliminate frequency-related losses, making a significant increase in switching frequencies realistically possible.

There is a lot of interest at the government level in these developments. Imagen Energy recently received $30 million from the Department of Energy’s ARPA-E Creating Innovative and Reliable Circuits Using Inventive Topologies and Semiconductors (CIRCUITS) program. Imagen is creating an SiC-based compact motor drive system to efficiently control high-power high-performance permanent magnet electric motors operating at extremely high speeds. Imagen Energy’s design seeks to address a major roadblock by overcoming large back electromotive forces.

On the enterprise side, the biggest advance since digital power management down to the board level is the emergence of software-defined power (SDP). A logical extension of digital communication capability, SDP takes system virtualization to a new level.

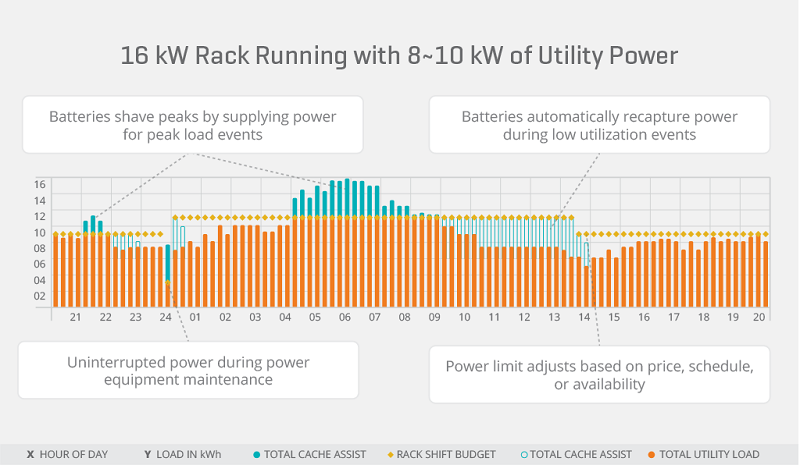

To address data center power usage dynamically, one needs to take an active role in power management, as even the best electronics can’t operate efficiently if they are not used well. Considering most system downtime is related to power and power-related issues (thermal management), software-defined power is a viable solution. SDP can manage power usage down to the individual subsystem on a given board in a given rack or server to help data center managers use the power that they have more efficiently.

Data center and other enterprise power demands require monitoring and automation at a very granular level to help data centers better manage risks as well as power. In this space, CUI and Virtual Power Systems have created ICE, a software/hardware solution leveraging existing infrastructures in data centers and networking systems. ICE intelligently and dynamically allocates power within a system using advanced algorithms and historical usage patterns to improve power utilization, reliability, and flexibility.

CUI Intelligent Control of Energy (ICE) Block solution. Image source: CUI.

CUI Intelligent Control of Energy (ICE) Block solution. Image source: CUI.

The ICE system, paired with CUI’s ICE Block, uses peak shaving to free up redundant power capacity, profiling power demand and battery storage to manage peak demand. In data centers providing 2N Service Level Agreements, ICE enables a data center to allocate excess power and use it for 1N SLA applications without impacting any 2N SLA applications. In failure events, power is routed to the 2N SLA applications first, with remaining power allocated based on established priority levels.

Infrastructures and applications

This was going to be two separate topics, but the two are also inextricably linked. Without a supporting infrastructure, no solution can go mainstream. The iPod succeeded because iTunes was the best music support infrastructure available at that time, a more important consideration than the device’s obvious functional advantages.

The current infrastructure issues are congruent with the two of the biggest issues in society — alternative energy and electric vehicles. Neither of these technologies will gain any traction or have any success in the marketplace at any significant level unless the required supporting infrastructures are in place.

However, unless range anxiety is eliminated, EVs won’t get very far (pun intended). Beyond bigger batteries and more efficient and lighter electronics, the charging infrastructure must be abundant and accessible. One of the players in the space, EVgo, is making a dedicated electric vehicle fast-charging station network for GM’s Maven car-sharing service.

Image source: EVgo.

Image source: EVgo.

Across the pond in Europe, players like Ionity — a company launched last year by BMW, Daimler, Ford, and the Volkswagen Group — are in the process of building a network of stations with a capacity of up to 350 kW across Europe with a target completion date of 2020.

The best thing about this new renaissance in power management is that it isn’t only restricted to power systems. More efficient sensors, processors, and other peripheral systems are also coming down in power consumption while going up in functionality, integration, and efficiency. The integration of these advances is resulting in the creation of some of the most advanced electronic systems ever created, and this new phase of development is just beginning.

Advertisement

Learn more about Electronic Products Magazine