Graphene may soon take the all-important step from novelty material to commercially viable product thanks to researchers from the University of Manchester and BGT Materials Limited. That’s because the group has figured out a way to print a radio frequency antenna using compressed graphene ink, and proven it is effective for use in radio-frequency identification tags and wireless sensors.

Additional benefits include flexibility, environmental friendliness, and the fact that the technology can be mass produced for considerably less than current antennas.

For those unfamiliar, graphene is an incredibly strong and conductive single-atom thick sheet of carbon — due to its unique set of electrical and mechanical properties, researchers have long sought practical uses for it. One of the material’s most successful commercial application thus far has been conductive ink, which can be used to print circuits and other electronic components.

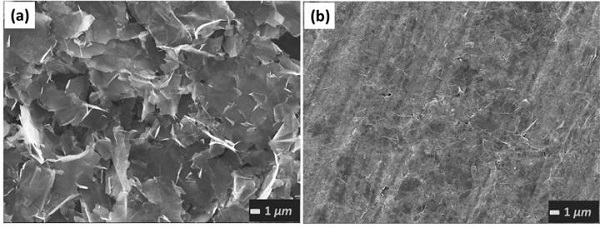

To create the graphene ink-based RF antenna, the researchers mixed graphene flakes with a solvent. Typically, the next step is to add a binder like ethyl cellulose to help the ink stick — it also helps the graphene conduct electricity better than binder-free ink. Instead of adding the binder, though, the researchers printed / dried the ink, and then compressed it with a roller. They found that in doing this they were able to increase the material’s conductivity by more than 50 times. This “graphene laminate”, if you will, was also two times more conductive than previous graphene ink made with a binder, and exhibited a more efficient radio frequency radiation.

To test the latter point, the group printed a compressed graphene laminate antenna onto a piece of paper. Measuring about 14 centimeters long and 3.5 millimeters across, the antenna was reported to have radiated radio frequency power effectively. The team expounded on the notion that they believe being able to print electronics on to cheap, flexible materials like paper and plastic could mean that wireless technologies like RFID tags that currently transmit identifying info on everything from animals to household items to vehicle parts in the shop, could become even more universal.

“Graphene based RFID tags can significantly reduce the cost thanks to a much simpler process and lower material cost,” said Xianjun Huang, who is the first author of the paper and a PhD candidate in the Microwave and Communications Group in the School of Electrical and Electronic Engineering.

The group plans to further work on graphene-enabled tags as well as sensors and wearable electronics. Read the full study, entitled “Binder-free Highly Conductive Graphene Laminate for Low Cost Printed Radio Frequency Applications,” in Applied Physics.

Advertisement

Learn more about Electronic Products Magazine