The wearable electronics and smart clothing industry is a multibillion-dollar operation, offering consumers everything from smart shirts that can track breathing patterns as you exercise to baby hats that can monitor your infant’s vitals remotely. Now, researchers at the University of California, San Diego are trying to make smart clothes even smarter by incorporating magnetic ink particles into components that could allow devices to self-heal when broken.

While the wearable market offers seemingly endless possibilities, most wearable electronics today are comprised of multiple rigid moving parts, making them both complicated and expensive to produce. One way to make devices cheaper is to mass-print electronic components using special electrically functioning inks that can produce lower-cost, more flexible devices, including batteries, sensors, and wearable circuits for smart clothing. The catch? Printed electronics are fragile.

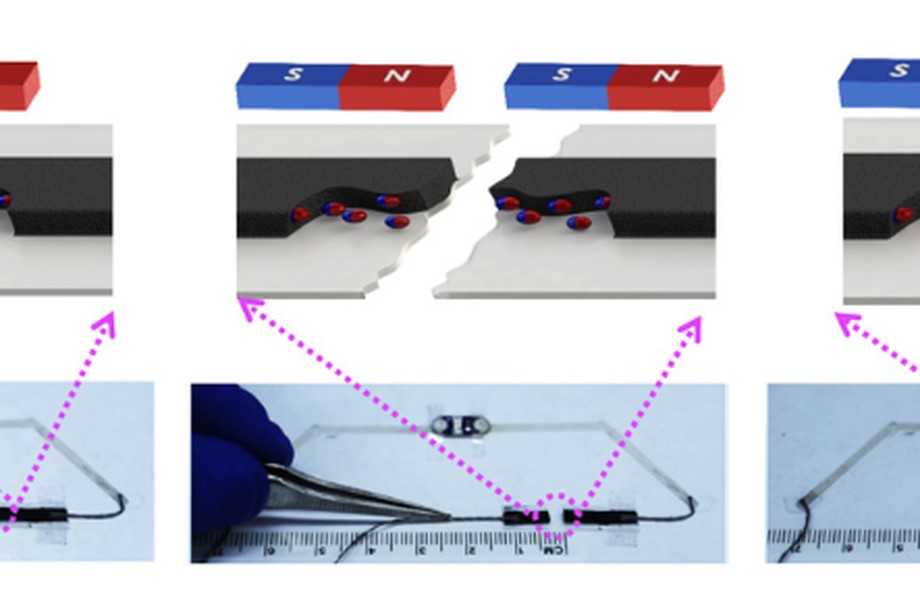

Joseph Wang and his team at the nanoengineering lab at the University of California, San Diego are developing a solution, attempting to streamline the wearable’s repair process by incorporating magnetic particles into the electronic print ink. The team uses neodymium magnets that have been pulverized into microscopic particles. The magnetic particles are then incorporated into the printer ink.

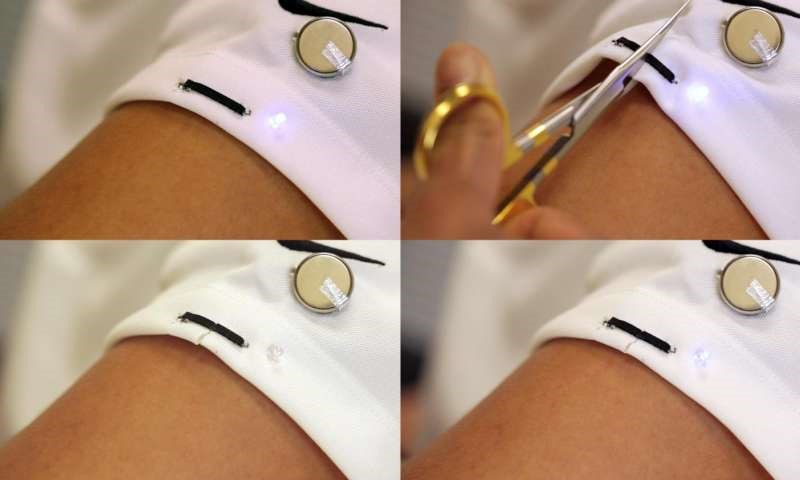

The self-healing concept relies on the fundamental magnetic principle of attraction; in the event of a tear, sensors printed within the ink would magnetically attract and re-attach to each other, closing the gap and effectively repairing the electronic connection. The ink can repair smart clothing cuts up to three millimeters long in 50 milliseconds. The ink is also low-cost, making it ideal for most wearables. Wang and his team estimate that $10 worth of ink material can yield hundreds of small devices.

“Just like human skin is stretchable and self-healing, we wanted to impart a self-healing ability to printed electronics,” said Amay Bandodkar, a member of the research team.

Traditional self-healing approaches use materials that rely on polymerization, a chemical reaction that mends broken fragments over a period of hours or days using chemical bonds activated by external inputs like heat. Magnets offer a simpler, faster method that does not require any additional light, heat, or chemicals.

The new aim of the research is to determine the optimal magnet-ink ratio for specific applications, with the ultimate goal being to incorporate magnetic self-healing into all devices from solar panels to implantable medical devices.

“If you’re wearing a device on your skin and it gets broken as you move around, you don’t have to throw it away,” said Bandodkar. “Within a few seconds, it’s all going to self-heal, and you can use it over and over again.”

Sources: The New York Times, The Verge

Advertisement

Learn more about Electronic Products Magazine