By NIGEL PICKETT, CTO and

STEVE REINHARD, Vice President of Business Development

Nanoco

www.nanocotechnologies.com

Quantum dots (right) offer more beautiful, vibrant and true-to-life color performance than traditional LCD technology (left).

Quantum dots have quickly become the next big advancement in the display industry, as a growing number of electronic display manufacturers are incorporating these brilliant tiny semiconductors into their backlight unit (BLU), improving color purity compared to conventional phosphor-based light-emitting diode (LED) backlit liquid-crystal displays (LCDs).

The excitement is driven by quantum dots’ unique ability to efficiently absorb and convert light, typically that of a blue LED, into very specific reds and greens — offering more beautiful, vibrant, and true-to-life color performance than traditional LCD technology.

With quantum dots, LCD screens finally have the capability to rival OLED products. Quantum dots also present an easy solution for display manufacturers to integrate into their products. Unlike OLED, which requires a complete and expensive overhaul of a production line, quantum dots take advantage of the existing LCD infrastructure, helping manufacturers bring innovative new technologies to consumers without exceptional expense or complexity.

Furthermore, the flexible nature of quantum-dot technology (as these particles are easily tunable simply by changing their size) is applicable to all sizes of displays — from large HDTVs to smaller devices like tablets and mobile phones.

Overcoming the traditional color triangle dilemma

Reds and greens have traditionally been difficult to mimic on displays due to color gamut constraints, which limit saturation levels. A wider color gamut gives manufacturers the ability to better match color according to how the eye sees it, so images on the screen appear more realistic.

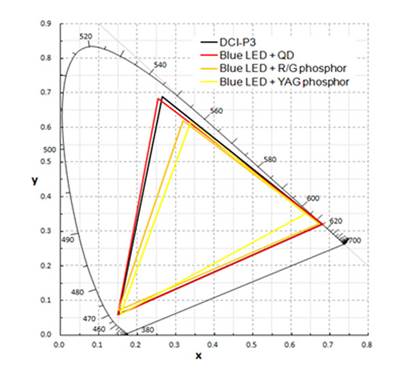

Today, the average gamut is about 72% of the DCI-P3 color triangle — meaning red more often looks closer to orange. At 100% gamut, viewers enjoy a true, precise red. However, achieving 100% color gamut via established technologies goes hand-in-hand with a trade-off in brightness or efficiency. The method involves heavy use of color filters, which ultimately leads to increasing efficiency losses.

Fig. 1: Color triangle, wide triangle equates to better color while narrow triangle equates to poor color.

Quantum dots offer a solution to this problem. Their highly saturated emissions can pass through the color filters with fewer losses, enabling high color purity with 100% of the DCI color triangle without sacrificing brightness.

Three approaches to integrating quantum dots into LCD screens

To achieve the near-perfect color quantum dots deliver to LCD screens, there are three approaches to consider:

- On-chip, where the quantum dots are deposited directly into the LED package

- On-edge, where the quantum dots are integrated within a component, such as a thin glass tube, that is positioned remotely from, but in close proximity to, the LEDs

- On-surface, where the configuration utilizes a remote quantum dot film that covers the surface area of the display

Though it has the highest material consumption, the on-surface geometry offers the advantage of operating near room temperature and is more easily and cost-effectively incorporated into the encasing display architecture.

Using the on-surface method, quantum dots, incorporated into a film located in between the LED light source and the LCD panel, are “excited” by light emitted from blue LEDs, transforming some of it into very pure green and red light. As a result, the LCD panel receives a richer white light and expands the range of color that the display can reproduce.

Getting beyond the cadmium concerns

It’s important to note that not all quantum dots are created equal. To date, a number of quantum dot products seeding the display market have contained cadmium. Cadmium is a toxic heavy metal, and its use is restricted under European and other environmental legislation due to the threat it presents to both human health and the environment. For example, the European Union’s Restriction of the use of certain Hazardous Substances (RoHS) Directive limits the amount of cadmium, lead, and mercury that can be included in electrical and electronic equipment placed in the European market. Cadmium is restricted to 100 ppm in homogeneous material — a figure 10 times less than that for mercury and lead.

The presence of cadmium has hindered the broad adoption of quantum dots in devices, keeping display manufacturers from realizing the benefits of the technology and products out of consumers’ hands. However, research into the synthesis and mass-manufacture of heavy metal-free quantum dots is of growing interest. Cadmium-free quantum dots offer a safer and more sustainable option for manufacturers and consumers, giving them all of the color benefits associated with the technology without the risks associated with toxicity or potential regulatory limitations.

Moving beyond cadmium-based quantum dots

Research into visible light-emitting, cadmium-free quantum dots for display applications has predominantly focused on indium phosphide. However, one of the shortcomings of indium phosphide for backlighting applications is that the full width at half-maximum (FWHM) of the emitted light is somewhat broader than that of II-VI materials, such as cadmium. In part, this originates from the quantum confinement effects in indium phosphide being stronger than those in cadmium, leading to a relatively larger change in emission wavelength from a given change in particle size.

This means that much narrower particle size distributions are required to obtain the same FWHM as that of cadmium-based quantum dots. For display applications, using quantum dots with a broader FWHM makes it a challenge to maximize the color gamut.

To overcome this problem, Nanoco has developed a unique quantum dot matrix of semiconductor alloy that is free from cadmium. By tailoring the structure of the quantum dot and allowing the strength of the bonding interactions to be manipulated, the quantum confinement effects are reduced. The result is that Nanoco has made considerable advances in narrowing the FWHM and improving the photoluminescence quantum yield of its cadmium-free quantum dots, making them perform nearly identically in an LCD as their cadmium counterparts do.

Research demonstrates high performance of cadmium-free quantum dots

Nanoco has developed a versatile molecular seeding methodology that enables good control of the quantum dot growth process. Further, the process allows the substitution of precursors containing the required elements at specific times that, along with precursor ligand design, enables the mechanism of precursor decomposition to be controlled, maximizing alloying when needed.

To demonstrate the efficacy of cadmium-free quantum dots in the on-surface configuration, a BLU was prepared using a film comprising Nanoco’s red and green cadmium-free quantum dots in a resin matrix, illuminated by blue LEDs. The film was optimized for Digital Cinema Initiatives P3 (DCI-P3) color space, with the color triangle displaying 95–98% coverage (depending on the filters used) and a white point close to the Commission Internationale de l’Eclairage (CIE) Standard Illuminant D65 after applying color filters.

The research results showed the color gamut of the film comprising the cadmium-free quantum dots was significantly larger than that of the conventional yellow phosphor Ce:YAG BLU, and comparable to that of the cadmium-based quantum dot television. This demonstrates that, despite the technical challenges, excellent optical performance can be achieved with cadmium-free quantum dots and films.

As further advancements are made in molecular seeding, we envision that even narrower FWHM values will be achieved in the future. The color gamut will be further improved not only by using quantum dots with a narrower FWHM but also, as the technology becomes more widely adopted, by tuning the color filters for use with quantum dots rather than for use with conventional rare-earth phosphors.

Research also assessed the lifetime of a BLU prepared using cadmium-free quantum dots. During 3,000 hours of testing, the photoluminescence intensity remained stable. Using a logarithmic extrapolation of the data, this yields a projected lifetime of at least 30,000 hours, which is sufficient for electronic display devices.

The results show that the company’s cadmium-free quantum dots offer a viable alternative for LCD BLU applications to commercially available displays using cadmium-based quantum dots, without the use of toxic heavy metals.

As legislation restricting the use of heavy metals gets ever restrictive, cadmium-free quantum dots are uniquely positioned as the future-proof quantum-dot display technology on the market. Thanks to this innovative technology, the future indeed looks more colorful (and safer) for both manufacturers and consumers.

Advertisement