Plastic 3D printing has its place in prototyping and education, but 3D printing in metal is being used to manufacture parts in a wide variety of industries. Metals are the fastest-growing segment of 3D printing, with printer sales growing at 48% and material sales growing at 32%, according to new IDTechEx report 3D Printing of Metals: 2015-2025.

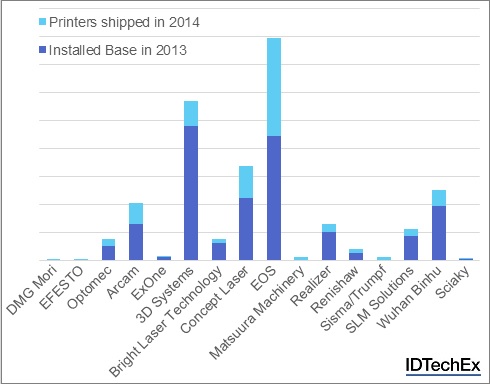

Fig 1. Breakdown of installed base and 2014 sales by company showing most companies are experiencing huge growth in sales and there are many new players in the market. Source: IDTechEx Research

Adoption by high-value low-volume industries

Because of the current speed, size and cost limitations, the high value, low volume industries such as aerospace and biomedical, have been the earliest adopters. GE Aviation is investing $3.5B in a new plant to house EOS M-280 printers to print 100,000 fuel nozzles by 2020. Arcam claims its 3D printers had been used to manufacture over 50,000 orthopedic implants so far. Both these industries demand titanium alloys, giving them a market share of 31% by volume. Aerospace is also heavily investing in cobalt alloys, nickel alloys and aluminum alloys.

Jewelers are also early adaptors of SLM technologies. There are many reasons jewelers are able to quickly adopt the technology; there are no qualifying standards for jewelry; jewelry designers are already good at CAD; they are used to subcontracting; they are skilled in finishing and polishing; they used to making bespoke items; and they crave design freedom and unusual designs. The jewelry industry is driving 3D printing in precious metals, with gold powder having a 49% market share by revenue.

More and more industries are adopting 3D printing

Dental suppliers, Argen Digital, offers metal substructures to make copings and bridges with the same properties as cast parts. Siemens are producing blades for gas turbines for power generation. NASA said that it intends to 3D print 80 to 100% of rocket engines in the future.

Advertisement