By Majeed Ahmad, contributing writer

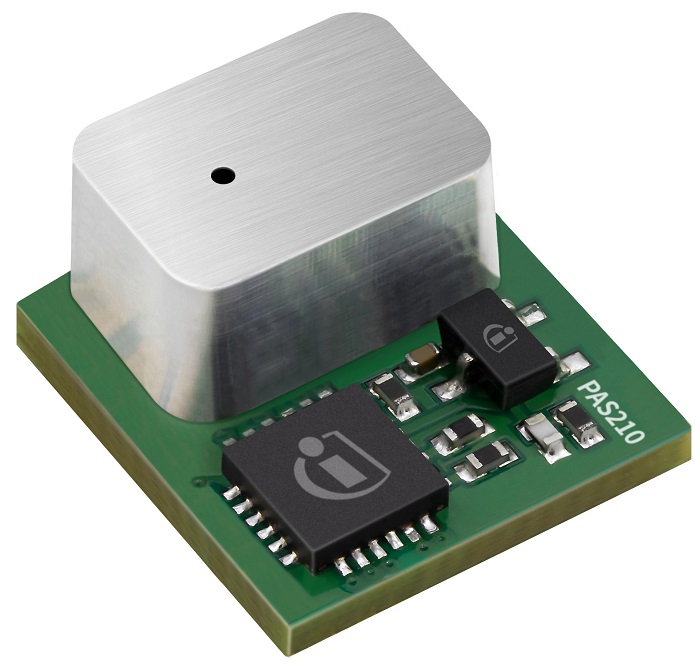

Infineon Technologies AG claims that its new CO2 sensor — based on the photoacoustic spectroscopy (PAS) technology — saves 75% board space compared to commercially available gas sensors. The XENSIV PAS210 sensor board comprises a detector, an infrared source, and an optical filter.

It employs a high-sensitivity MEMS microphone as a detector, and a microcontroller converts the MEMS microphone output into a ppm reading via the serial I²C, UART, or PWM interface. A MOSFET on the board drives the infrared source.

Its simple design, surface-mount capability, and direct ppm readings enable an easy and fast integration into low- and high-volume applications alike. The CO2 sensor covers a range from 0 ppm to 10,000 ppm with an accuracy of ±30 ppm, or ±3% of the reading. Moreover, in a pulsed mode, the PAS210 sensor is designed to have a lifetime of 10 years.

Infineon is targeting this CO2 sensor at applications like demand-controlled ventilation in smart homes and building automation. The new gas sensor can also be used in various indoor air quality IoT devices such as air purifiers, thermostats, weather stations, and personal assistants.

Engineering samples are expected to be available in the first half of 2020, and production is planned in the second half of 2020. Infineon will demo the XENSIV PAS210 sensor at Sensor+Test in Nuremberg and at Sensors Expo, both in June 2019.

Advertisement

Learn more about Electronic Products Magazine