This post sponsored by Texas Instruments.

Manufacturing operations and industrial service facilities require a lot of specialty machines. Everything from toys to medicines and power are mass-produced and it is the machines, assembly lines, and robots that make it possible to perform these often complex and precise tasks cost-effectively. In many cases, specialty machines are needed to handle a new process such as a new powder-coat formulation or plating process.

Machine designers have some sciences nailed down. Conveyer belts and motorized assembly lines are out-of-the-box functions these days, and even robotic grabbers and placers come in all sizes, shapes, and form factors. But, even established technologies cannot stand still. If you don’t find a way to innovate and improve, then the competition will, providing them with a distinct advantage.

As a result, older factories just cannot compete with their newer counterparts. A factory from the 50s does not have the same “technology” as a factory built in the 70s, which can’t keep up with a factory constructed in the 90s, and so on. It is a narrow efficiency gap that allows the more innovative producer to offer their product and/or service at a lower cost in a market where margins are already bone-slice thin.

This means that entirely new factories and facilities need to be built constantly, or that the existing factories and industrial facilities need to be modular in nature. Both are occurring and automation technology is tightly interwoven at all levels; however, automation and efficiency gains do not happen overnight. Processes need refinement and continuous improvement, and microcontrollers are a key part of this.

Micros, Micros Everywhere

The ability to create a single-chip device that entirely handles a given process is the ideal solution to a specific problem, and microcontrollers allow engineers to do just that. A single-chip microcontroller can be programmed to be a self-contained solution with mixed-signal capabilities, communications, and processing horsepower to implement rather complex algorithms all by itself. This makes them ideal as part of a sensor interface or control node in a complex machine’s web.

But designers need a level of consistency. They don’t have time to learn a dozen different microcontrollers’ intricacies and quirks. Designers want to learn and master the tools, architectures, peripherals, timers, DMAs, A/D and D/A converters, PWMs, UARTs, IIC, SPI, and so on, only once in order to spend more time designing and testing. In order to do this, designers need a scalable, flexible, feature- and peripheral-rich family of processors with a common core, toolset, and knowledge base.

A Family Affair

The MSP family of processors from Texas Instruments is a mature and growing family of 16- and 32-bit microcontrollers that is ideal for dedicated devices in industrial settings. More than 500 configurations for the low-power MSP processors include small 8-pin MCUs with 2 Kbytes of flash, up to the hefty MSP430F677x with up to 512 Kbytes of flash and 64 Kbytes of RAM in a 128-pin LQFP package with plenty of I/O (90) and mixed-signal peripherals.

Ultra-low-power features help remote sensors and controllers draw less and operate from battery backup for more than 20 years using coin-cell batteries in some cases. Smart peripherals and development kits that focus on specific areas of technology are an added bonus.

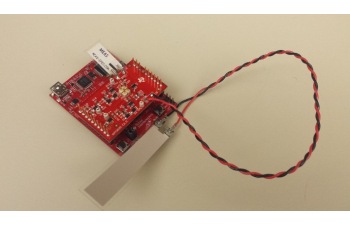

For the next-generation assembly line, the MSP MCU family is supported with reference designs and evaluation kits for machine functions such as the Three-Phase Brushless Motor Drive for Sensorless Trapezoidal Motor Control, or Low-Voltage Brushed Motor Systems. Even off-the-beaten-path applications like the MSP microcontroller-based Piezoelectric Airflow Sensors are supported with a reference design (Figure 1), and the Low-Power Orientation Trackers are useful for factory- or industrial-position and orientation sensing.

Figure 1: The MSP family of MCUs includes a multitude of narrowly focused reference designs, demonstration, and evaluation kits for a variety of functions such as this piezoelectric airflow-sensor reference design and kit. (Source: Texas Instruments)

Another benefit of the MSP family from Texas Instruments is the availability of FRAM blocks placed inside the core. FRAM is high-endurance and rugged non-volatile memory that can protect data and code from EMI, RFI, EMP, ESD, and more.

When faced with multiple tasks and challenges, a consistent well-engineered family of processors such as Texas Instruments’ MSP family can provide a common platform from which to launch.

MSP430FR5969

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

MSP432P401R

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

MSP430FR4133

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

MSP430F5529

For more information about this product, click here.

To request a sample, click here.

o buy now at Mouser, click here.

MSP430FR6989

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

MSP430FR5739

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

MSP430F5172

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

By: Jon Gabay

Advertisement

Learn more about Texas Instruments