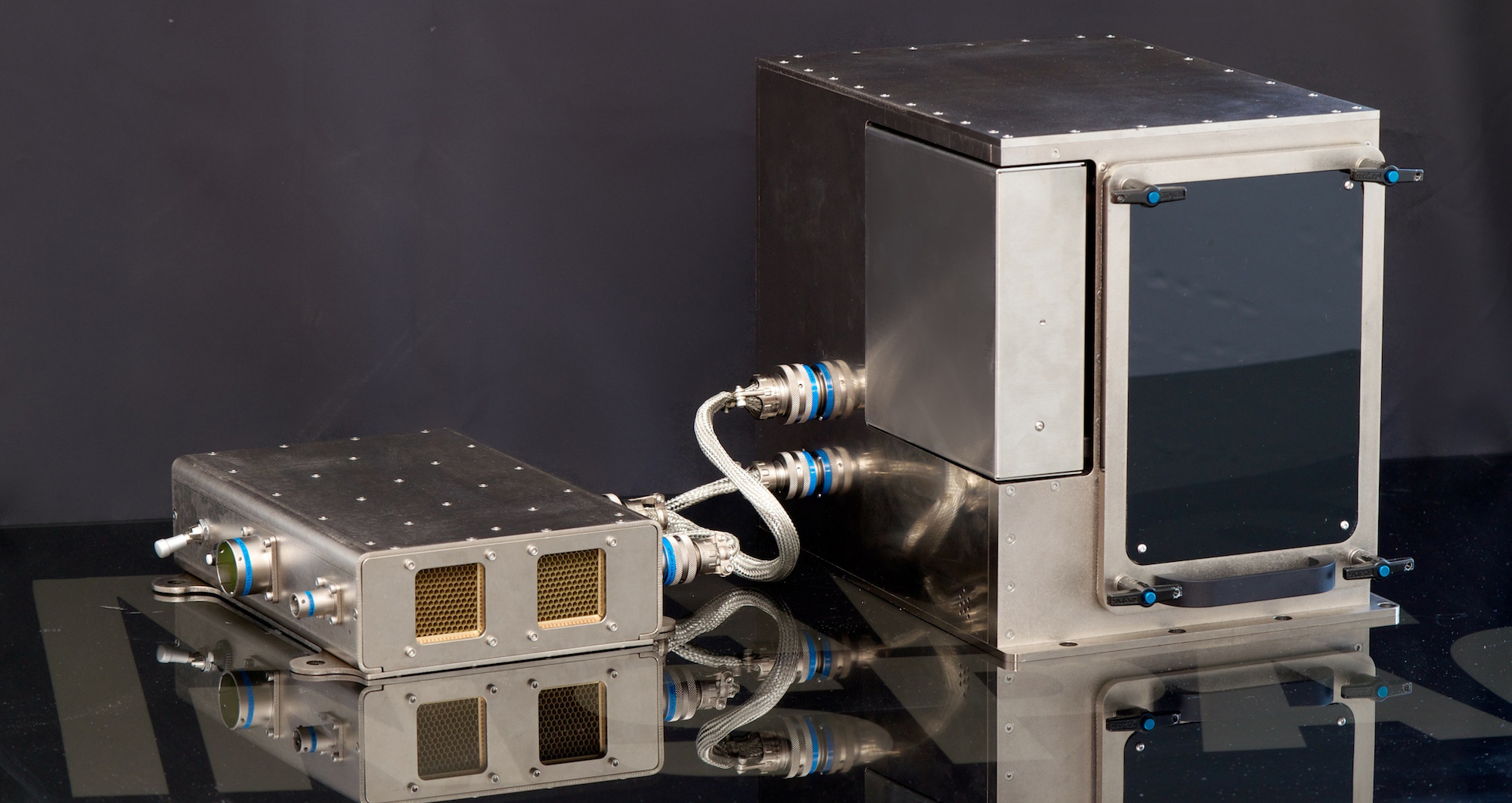

Among the bevy of scientific experiments shuttled aboard SpaceX’s recently launched Dragon spacecraft was the Zero-G, the first 3D printer capable of operating in microgravity. The delivery is scheduled to rendezvous with the International Space Station on September 23, bringing fabrication aboard PCB pipes and other plastic parts.

The idea of manufacturing components, tools, and other assets directly in space is an alluring prospect, considering the millions of dollars in cost spent transporting even a small amount of material into space. Made In Space, the firm spearheading the printer’s development, believes that the instrument will accelerate space development and exploration by freeing up additional assets which can then be reinvested in R&D.

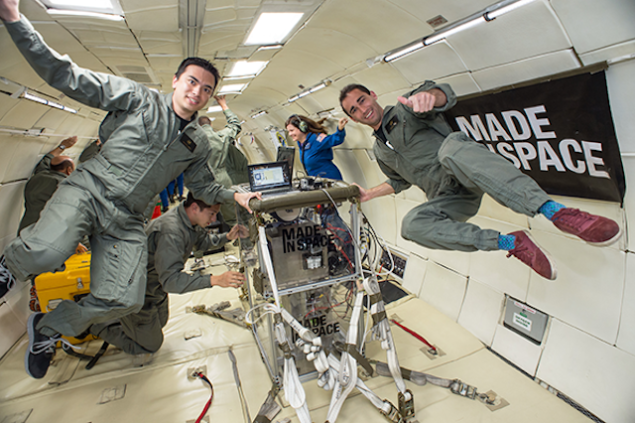

Zero-G isn’t your typical high-end Makerbot or consumer model printer; it was developed in a joint partnership between NASA, MSFC, and Made In Space with the intention of testing the long-term effects of microgravity on 3D printing. Since 2010, 30,000 hours of testing have gone toward creating the working prototype, including the time spent aboard NASA’s modified Boeing 727 that simulates zero-g using parabolic flight paths.

“The printing process itself is very similar to plastic extruding 3D printers on Earth,” said Made In Space engineer, Brad Kohlenberg, to Gizmodo, “but the adjustments that were needed to make the printer work both in micro gravity and aboard the closed-loop system of the ISS necessitated building a new printer from the ground up.”

Once the Zero-G arrives aboard the ISS, it will be placed into a “Microgravity Science Glovebox,” otherwise known as a self-contained microgravity testing space. The Made In Space team can then remotely control the printer from Earth to fabricate basic items and “test coupons,” or samples designed to verify that the printing process aboard the space station parallels that on Earth.

The completed test coupons will eventually find their way back aboard the Dragon on a return trip to Earth for evaluation. The current prototype exclusively uses ABS plastic, but a new variation scheduled for a 2015 ISS delivery expands both the build volume and the material capacity to include multiple types.

“This is more than a 3D printer. It’s more than a machine shop in space. It’s a landmark for humanity. For the first time in the history of our species, we will be manufacturing tools and hardware away from the Earth. Now that we’ve made this breakthrough, the sky is no longer the limit for additive manufacturing – the era of off-world manufacturing has begun,” says Aaron Kemmer, CEO of Made In Space, in a recent press release.

Advertisement

Learn more about Electronic Products Magazine