By Jean-Jacques DeLisle, contributing writer

NextFlex, America’s Flexible Hybrid Electronics (FHE) Manufacturing Institute, recently announced a new type of flexible microcontroller module that could have big implications for engineers, prototypers, and hobbyists everywhere. Here’s how this new technology can bring about many advancements to the rapidly growing realm of Arduino microcontroller modules.

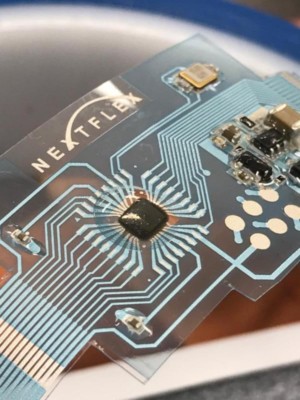

NextFlex’s new technology can bring many advancements to the rapidly growing realm of microcontrollers. Image source: NextFlex.

The advancement that NetFlex has made to Arduinos comes in response to several problems that have plagued the original open-source microcontroller modules. A microcontroller is a device with a programmable control chip with various input and output slots, which can be programmed using a simple code to control other various devices or read sensors and relay the information to a computer or other device. Arduinos are open-source modules based on a microcontroller, and they run on a notoriously easy-to-learn code, which is making them extremely sought after for prototyping new technology. The popularity of Arduinos in the last few years has grown rapidly with various iterations available, such as the Arduino mini, but until now, they have been limited by certain physical restrictions. Typical Arduinos are built using standard PCB boards and are, therefore, rather rigid and bulky. Due to their exposed electronics, they are also rather fragile. NextFlex has solved these problems with a new manufacturing process — flexible hybrid electronics (FHEs) — that uses flexible plastic instead of a PCB and a printed conductive layer allowing the modules to be fully flexible as well as highly durable.

Not only is this new technology, which happened to be sponsored by the United States Air Force Research Laboratory (LARF), expected to be useful in many ways, it’s cheaper and easier to manufacture, cutting the manufacturing steps by two-thirds. “The possibilities for FHE technology are virtually limitless,” said Dr. Benjamin Leever, the AFRL advanced development team leader and NextFlex Government Chief Technology Officer. “Proving the manufacturability of this technology through an open-source platform will expand FHE’s reach even further by providing everyone from industrial product developers to high school students with the opportunity to innovate on new electronics concepts. We are pleased to have teamed with NextFlex on this project and look forward to the next steps in the optimization process.”

This advancement could have far-reaching implications for industry as well as for the military. “Being able to demonstrate the process manufacturability of a low-cost, easy-to-deploy, and truly flexible platform gives everyone — and by that, I mean everyone that feeds into the Arduino open-source developer community — the ability to create and speed to market innovative new products that harness the power of FHE,” said Jason Marsh, NextFlex’s director of technology. With these new flexible microcontrollers hitting the market soon, there’s no telling what amazing, new technology we could see in the future, but one thing is for sure: The march of progress just got a little more spring in its step.

Advertisement

Learn more about Electronic Products Magazine